Method for preparing olive phenol natural antioxidant

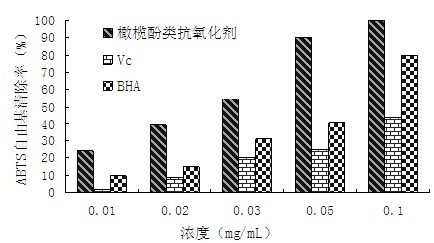

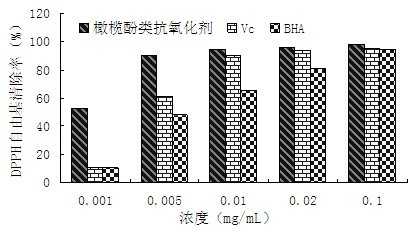

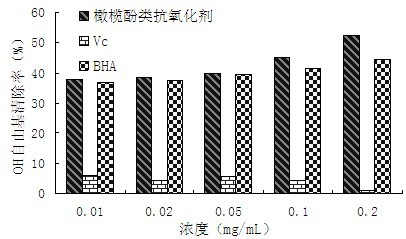

A natural antioxidant, olive phenol technology, applied in the direction of chemical instruments and methods, separation methods, compositions to inhibit chemical changes, etc., to achieve the effect of simple operation, strong free radical scavenging ability, antioxidant activity, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Use fresh olive fruit as raw material, remove the moldy and rotten bad fruit, wash with clean water to remove the sediment and foreign matter on the surface of the fruit, put it in boiling water for 3-5 minutes, and then crush and remove the core after cooling. The olive pulp after pitting is added with water at a mass ratio of pulp to water of 1:0.5 for beating, and the particle size of the pulp is controlled at 1-3 mm. Vacuum-dry the olive pulp, crush it, and pass through a 20-60 mesh sieve to obtain olive pulp powder. According to the mass volume ratio (W / V) of fruit powder and alcohol solution is 1:10, add 60%~80% food grade alcohol solution, and extract phenols with ultrasonic-microwave synergistic extraction apparatus, the ultrasonic frequency is 40 KHz, and the power is 50 W, the microwave frequency is 2450 MHz, the power is 100 W, and the extraction time is 3 min. The olive phenol extract was concentrated in a vacuum to remove alcohol to obtain a crude olive ph...

Embodiment 2

[0043] Use fresh olive fruit as raw material, remove the moldy and rotten bad fruit, wash with clean water to remove the sediment and foreign matter on the surface of the fruit, put it in boiling water for 3-5 minutes, and then crush and remove the core after cooling. The olive pulp after pitting is added with water at a mass ratio of pulp to water of 1:0.8 for beating, and the particle size of the pulp is controlled at 1-3 mm. Vacuum-dry the olive pulp, crush it, and pass through a 20-60 mesh sieve to obtain olive pulp powder. Add 60%~80% food grade alcohol according to the mass volume ratio (W / V) of fruit powder and alcohol solution as 1:12, and extract phenols with an ultrasonic-microwave cooperative extraction apparatus, the ultrasonic frequency is 40 KHz, and the power is 50 W, the microwave frequency is 2450 MHz, the power is 300 W, and the extraction time is 2 min. The olive phenol extract was concentrated in a vacuum to remove alcohol to obtain a crude olive phenol ex...

Embodiment 3

[0045] Use fresh olive fruit as raw material, remove the moldy and rotten bad fruit, wash with clean water to remove the sediment and foreign matter on the surface of the fruit, put it in boiling water for 3-5 minutes, and then crush and remove the core after cooling. The olive pulp after pitting is added with water according to the mass ratio of pulp and water at 1:1, and the particle size of the pulp is controlled at 1-3 mm. Vacuum-dry the olive pulp, crush it, and pass through a 20-60 mesh sieve to obtain olive pulp powder. Add 60%~80% food grade alcohol according to the mass volume ratio (W / V) of fruit powder and alcohol solution as 1:15, and extract phenols with an ultrasonic-microwave cooperative extraction apparatus, the ultrasonic frequency is 40 KHz, and the power is 50 W, the microwave frequency is 2450 MHz, the power is 450 W, and the extraction time is 1 min. The olive phenol extract was concentrated in a vacuum to remove alcohol to obtain a crude olive phenol ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com