Additive with high heat stability for jet fuels

A jet fuel and stability technology, applied in fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve problems such as hindering the normal flow of fluid, fuel temperature limitation, engine nozzle deformation, etc., to achieve the suppression of deposit formation, stable and reliable performance , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

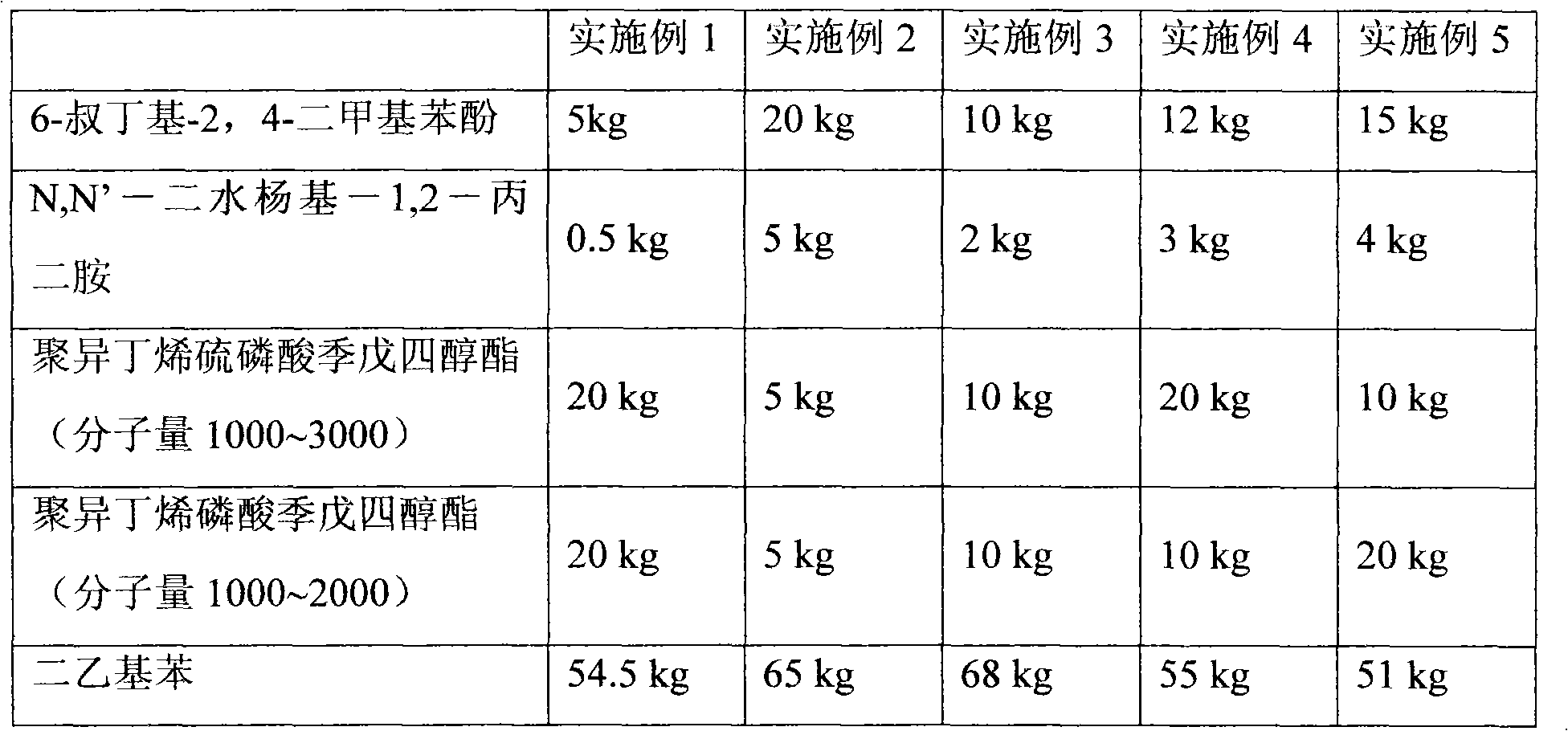

[0028] Embodiments 1-5: Preparation of Jet Fuel High Thermal Stability Additive

[0029] Weigh 6-tert-butyl-2,4-dimethylphenol, N,N'-disalicyyl-1,2-propylenediamine, polyisobutylene thiophosphate pentaerythritol ester (molecular weight 1000 ~3000), polyisobutylene phosphate pentaerythritol ester (molecular weight 1000~2000), diethylbenzene, put them into a stainless steel kettle, and stir at a speed of 100rpm for 3 hours at room temperature to obtain a jet fuel high thermal stability additive. Before mixing, the various components should be dissolved and then mixed, and the stirring should be strengthened to prevent some components from depositing at the bottom and affecting performance.

[0030] Table 1: Formula table of embodiments 1 to 5:

[0031]

Embodiment 6~10

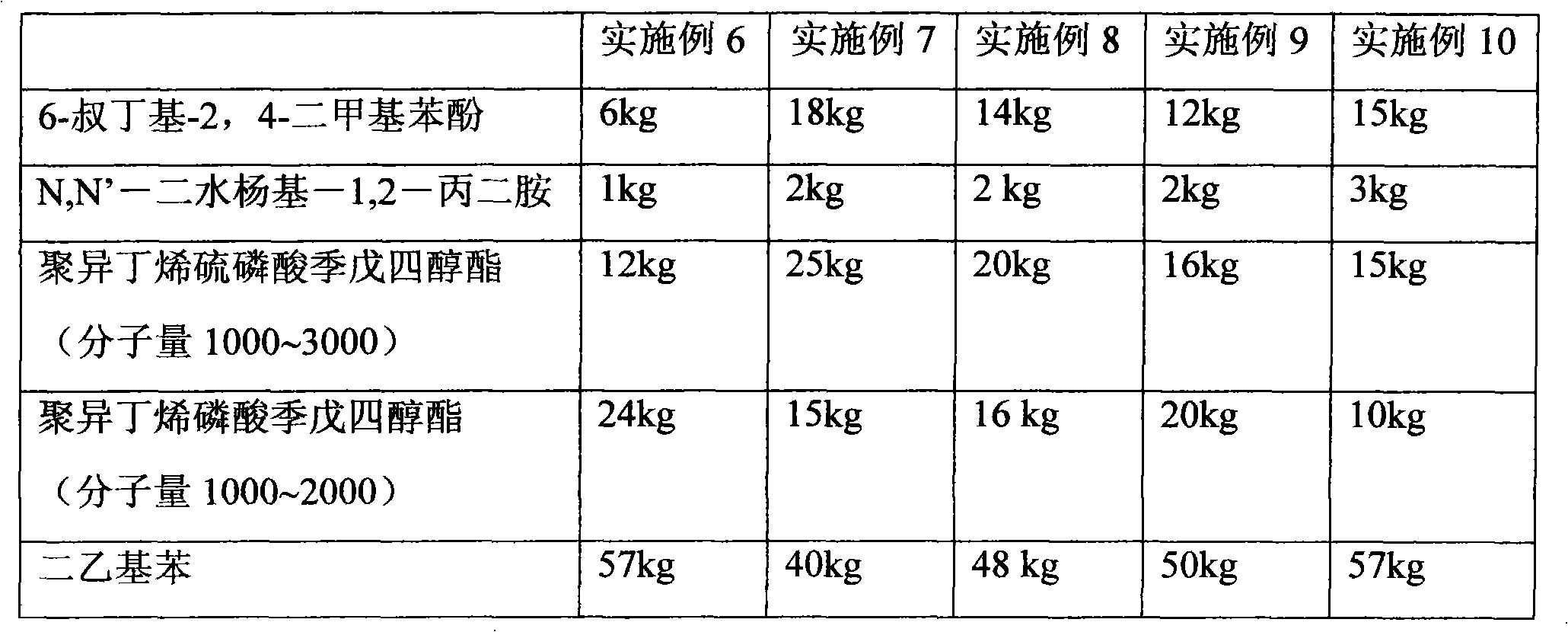

[0032] Embodiments 6-10: Preparation of Jet Fuel High Thermal Stability Additive

[0033] Weigh respectively 6-tert-butyl-2,4-dimethylphenol, N,N'-disalicylic-1,2-propylenediamine, polyisobutylene thiophosphate pentaerythritol (molecular weight 1000 ~3000), polyisobutylene phosphate pentaerythritol ester (molecular weight 1000~2000), diethylbenzene, put them into a stainless steel kettle, and stir at a speed of 100rpm for 3 hours at room temperature to obtain a jet fuel high thermal stability additive. Before mixing, the various components should be dissolved and then mixed, and the stirring should be strengthened to prevent some components from depositing at the bottom and affecting performance.

[0034] Table 2: Formula table of embodiments 6-10:

[0035]

[0036] Experimental example 1 The detection of high heat adding stabilizer to the jet fuel prepared in Examples 1-10

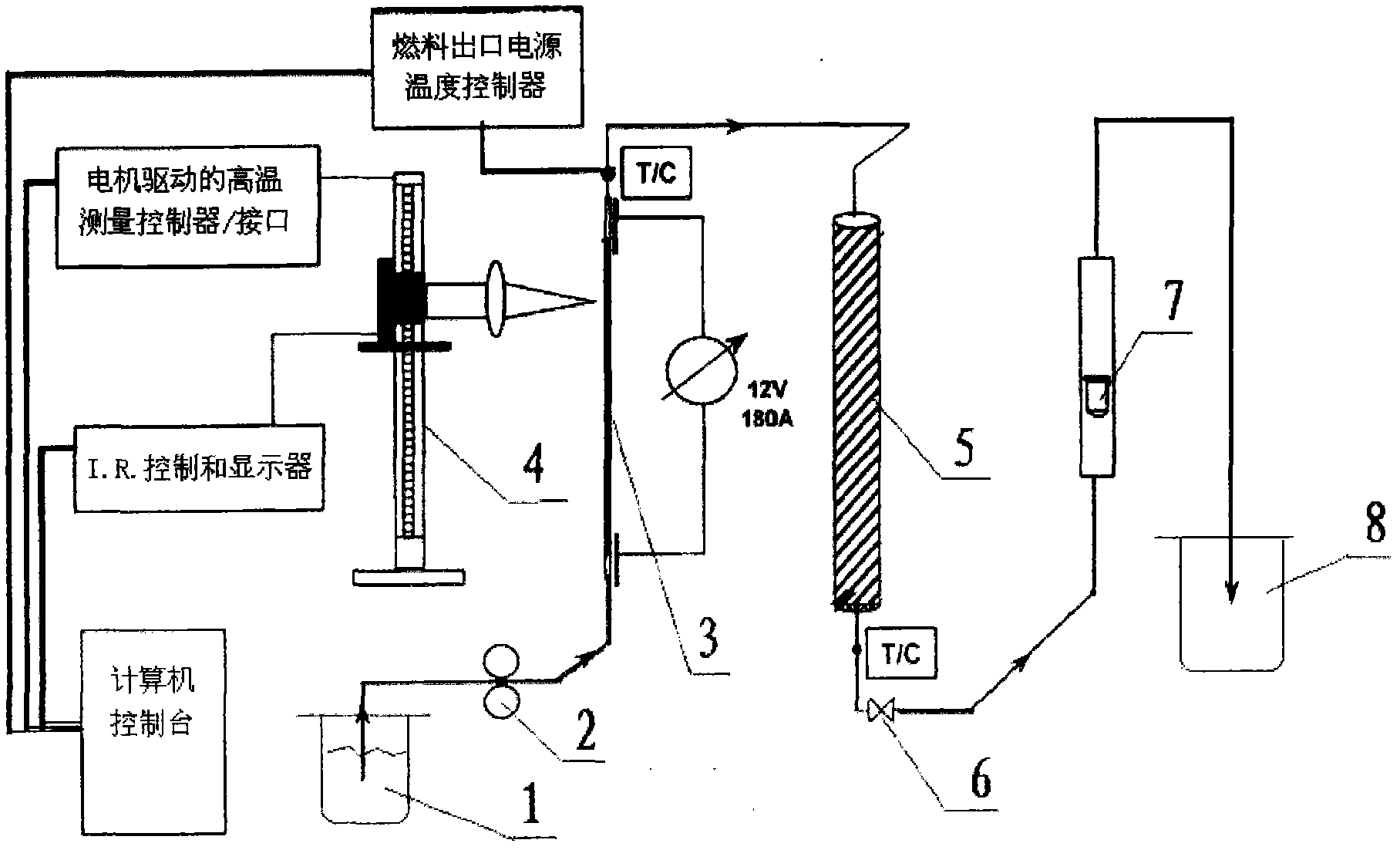

[0037] Jet fuel thermal oxidation stability test method (JFTOT method) refer to the national stan...

experiment example 2

[0045] HiReTS testing machine is a new generation of thermal oxidation stability testing machine developed by Shell Global Solutions and Fuels Business Group, which is specially used to evaluate the thermal stability of fuel before delivering fuel to consumers. Since the HiReTS test machine is designed for quantitative analysis, and the working state is the same as the high Reynolds number state of the actual fuel nozzle (Reynolds number is about 13000), it is generally considered that it is different from JFTOT (and other laminar flow test equipment, Reynolds number About 10) can get more associated data than .

[0046] HiReTS standard test method, in line with ASTM D6811-02 standard, officially released in July 2002. This method is used to determine the dynamic thermal oxidation stability of aviation turbine fuel in turbulent flow state, which is different from JFTOT for the determination of fuel stability in laminar flow state. This method simulates the actual turbulent wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com