Biogas pool for improving gas yield through complementation of solar photo-thermal electric generation and photovoltaic electric generation

A technology of solar cells and photothermal power generation, applied in the field of biogas digesters, can solve the problems of insufficient gas production rate of biogas digesters, lack of temperature increase, heat preservation, and low economic benefits of scattered chicken egg production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

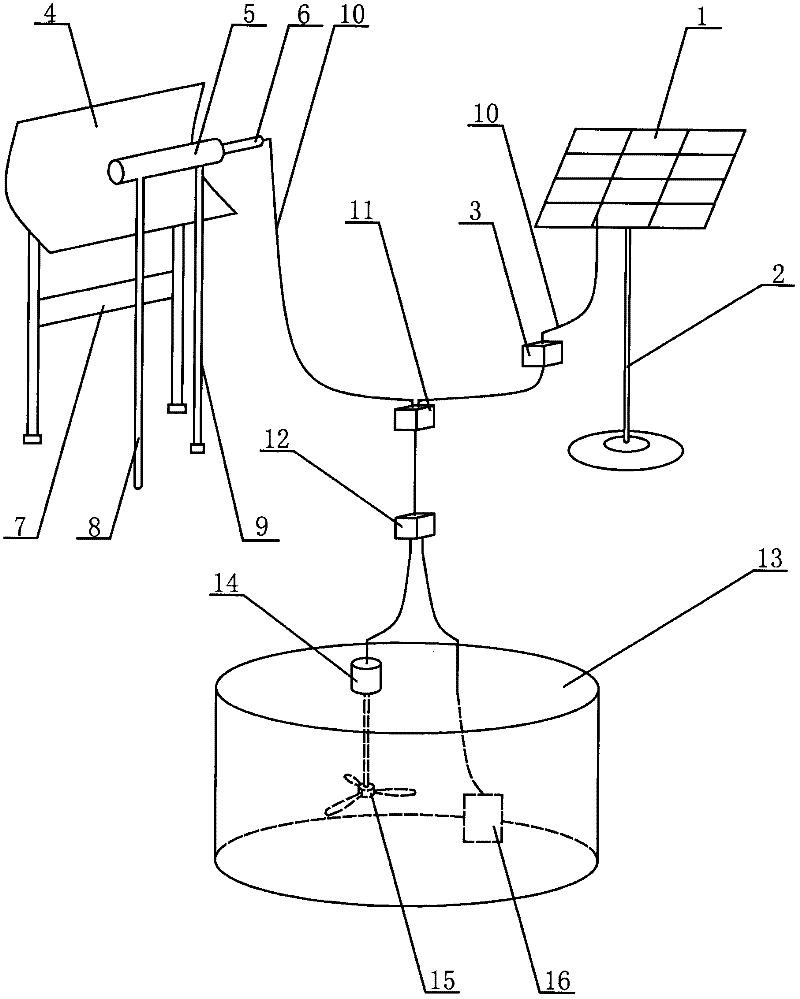

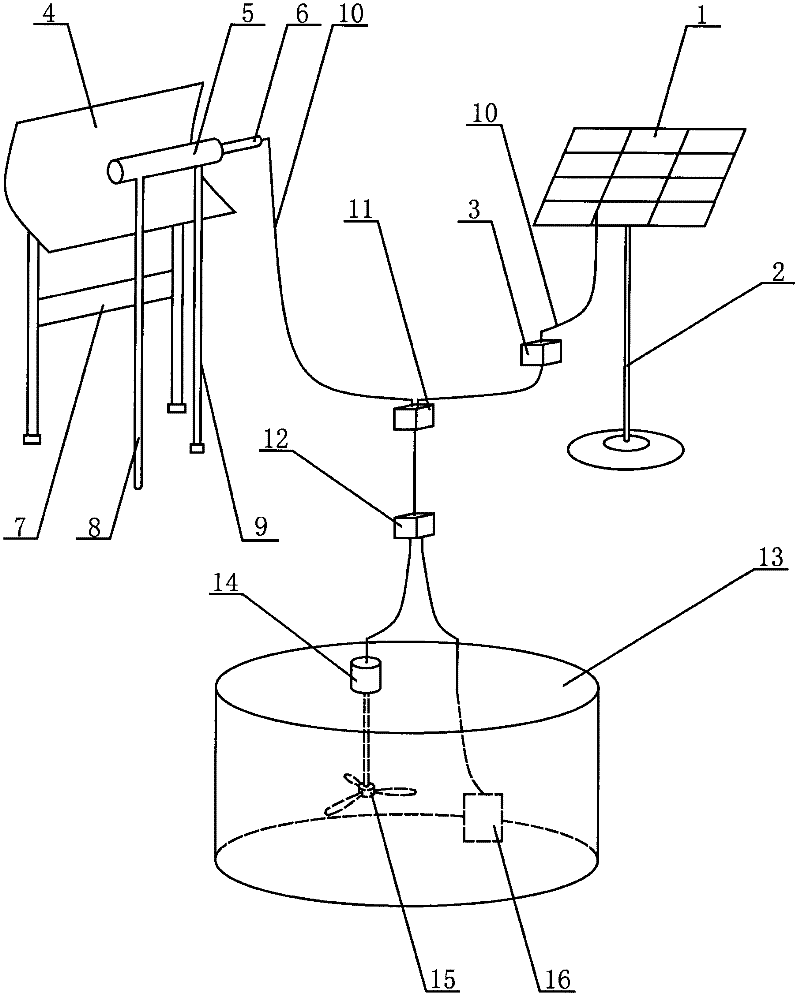

[0024] Sunlight irradiates the parabolic mirror to reflect and gather heat energy, and the liquid water in the heat exchange device is heated to generate water vapor to drive the turbogenerator to generate current, and the current is input into the confluence through the conductive wire; the sunlight irradiates the monocrystalline silicon solar cell to generate current, and the current passes through the conductive wire. Line input controller, the current output from the controller is input into the confluence through the conductive wire, the two parts of the photothermal and photovoltaic currents are combined in the confluence and then input into the shunt through the conductive wire, and the current is divided into two parts in the shunt, one part of the current The heating device in the biogas digester is input through the conductive wire, and the electric energy is converted into heat energy in the heating device, and the heat energy is used to increase the temperature of th...

Embodiment 2

[0026] Sunlight irradiates the parabolic mirror to reflect and gather heat energy, and the liquid water in the heat exchange device is heated to generate water vapor to drive the turbogenerator to generate current, which is input into the confluence through the conductive wire; the sunlight irradiates the polycrystalline silicon solar cell to generate current, and the current is input through the conductive wire The controller, the current output from the controller is input into the confluence through the conductive wire, the two currents of solar heat and photovoltaic are combined in the confluence and then input into the shunt through the conductive wire, and the current is divided into two parts in the shunt. The wire is input to the warming device in the biogas digester, and the electric energy is converted into heat energy in the warming device, and the heat energy is used to increase the temperature of the fermentation biogas liquid; the other part of the current is input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com