Glass fiber reinforced plastic centrifugal extractor and method for implementing extraction transformation of metal compounds

A glass fiber reinforced plastic and extractor technology, applied in the field of metallurgy, can solve the problems of poor fluidity, difficult operation of extraction equipment, increased viscosity, etc., to achieve the effects of small retention, improved productivity and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

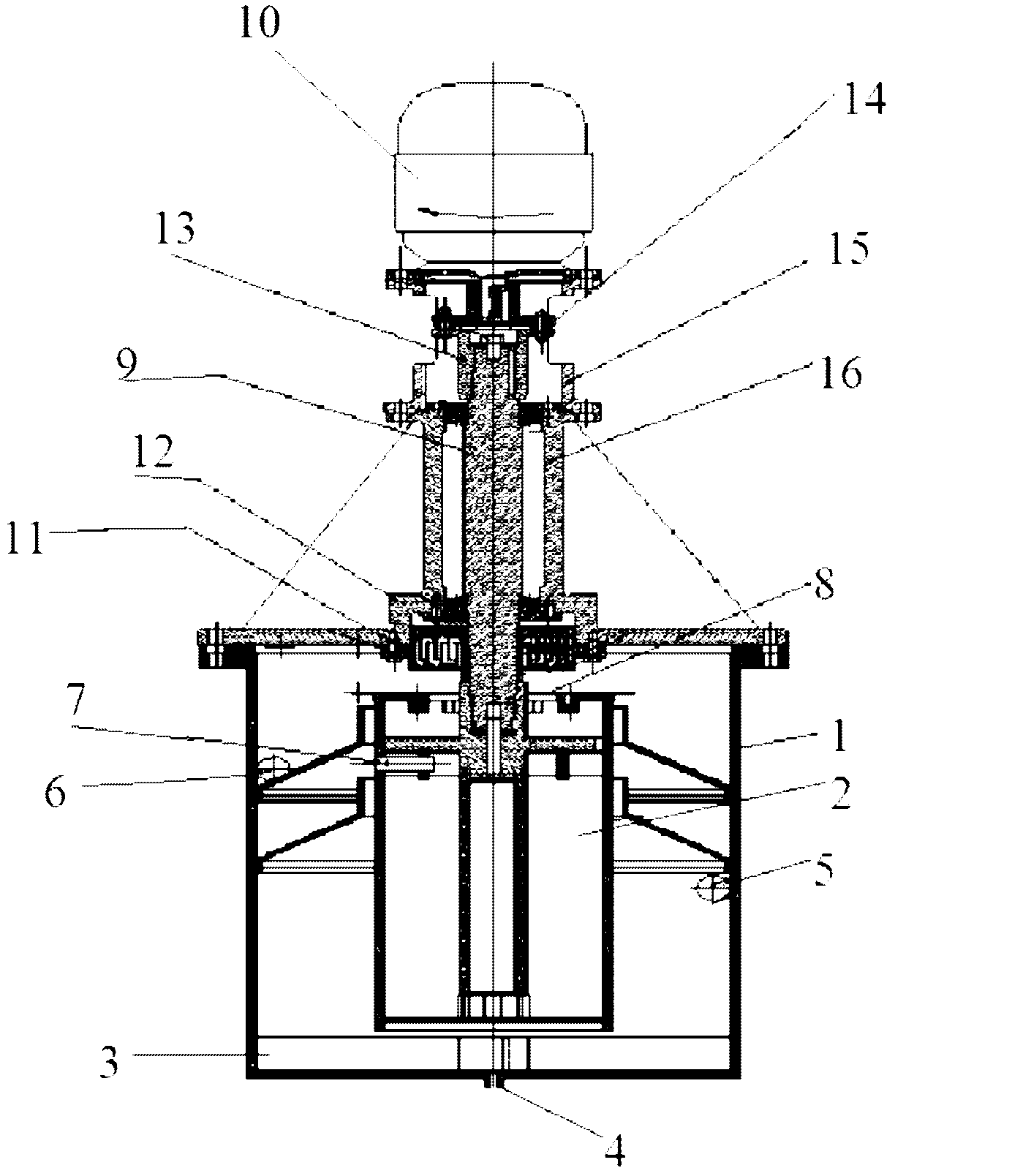

[0026] A kind of fiberglass centrifugal extractor, such as figure 2 As shown, the drum 2 is placed in the housing 1, the bottom of the drum 2 is connected with the mixing guide plate 3, the bottom of the mixing guide plate 3 is provided with a discharge port 4, one side of the housing 1 is provided with a feed liquid inlet pipe 5, and the other side is provided with a There is a heavy phase outlet pipe 6, the upper part of the drum 2 is provided with a light phase liquid ejection pipe 7, and the top of the drum 2 is provided with a heavy phase liquid ejection outlet 8, the drum 2 is connected with the motor 10 through the main shaft 9, and the main shaft 9 is close to One end of the drum 2 is provided with a labyrinth fixing part 11 and a labyrinth moving part 12, a coupling 13 and a coupling flexible part 14 are provided at the joint between the drum 2 and the main shaft 9, the lower end of the motor 10 is connected with the motor positioning seat 15, and the motor The lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com