Carbon fiber surface C/Si composite coating and preparation method thereof

A composite coating and carbon fiber technology, applied in the field of multifunctional C/Si composite coating and its preparation, can solve the problems of reducing carbon fiber strength, large carbon fiber damage, uneven coating, etc., so as to improve oxidation resistance and reduce damage , the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

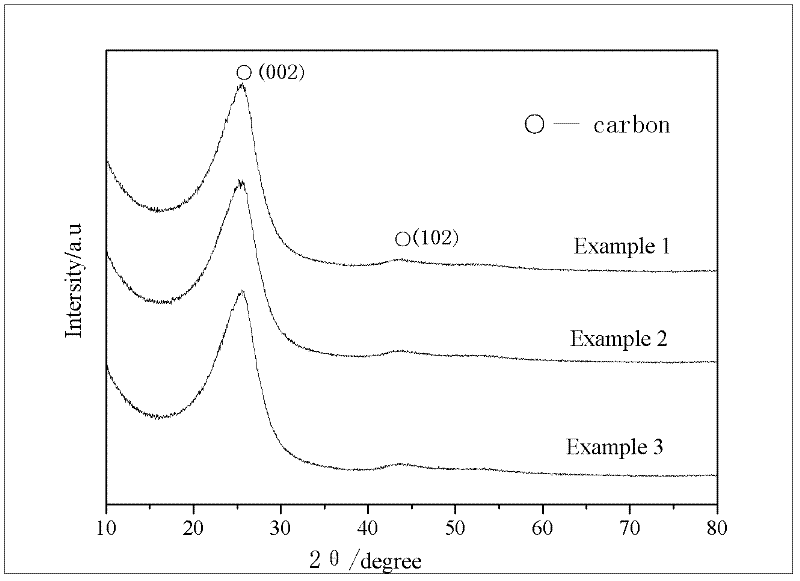

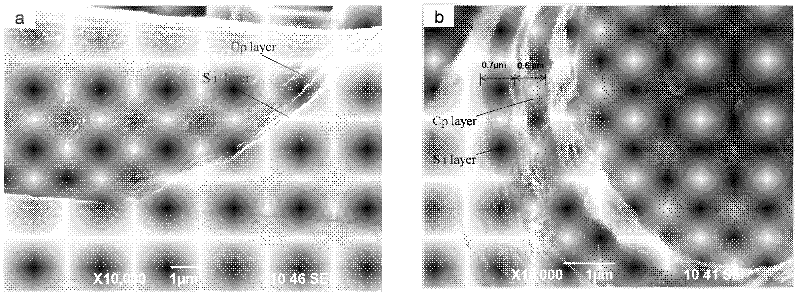

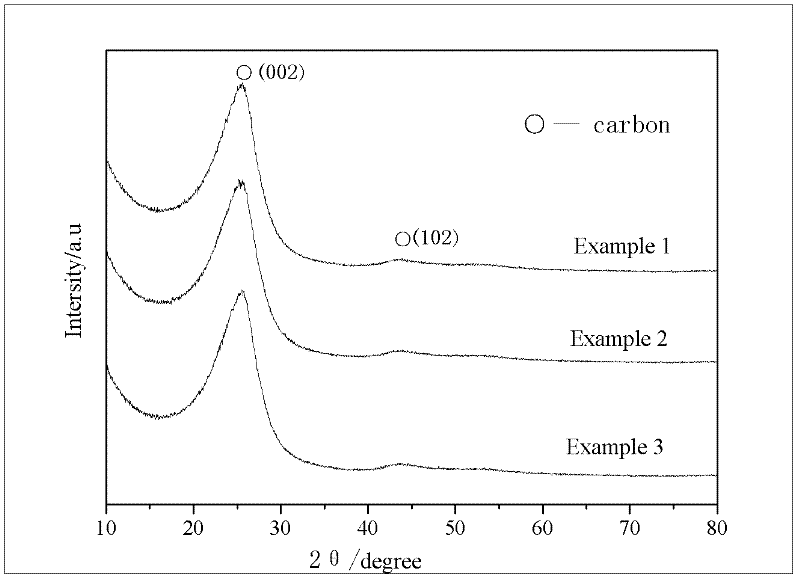

Embodiment 1

[0022] Example 1 : Place the carbon fiber sample in absolute ethanol, clean it with an ultrasonic cleaner for 15 minutes, then take it out, and dry it at 60°C for later use;

[0023] Put the processed carbon fiber sample in the LPCVD furnace, evacuate to -0.096MPa, close the vacuum valve, time 6min, the index of the vacuum gauge remains unchanged, the furnace is well sealed, and start the follow-up test;

[0024] Pass 0.2L / h of protective gas Ar, open the vacuum valve, maintain a negative pressure of -0.096MPa, and the temperature in the LPCVD furnace rises to 1050°C within 3 hours;

[0025] When the temperature rises to 1050°C, start to pass CH 4 , the flow rate is controlled at 20L / h, and the deposition time is 3h. After the preparation of the inner coating pyrolytic carbon is completed, the flow of CH is stopped. 4 ;

[0026] Adjust the temperature of the furnace chamber, the temperature is set to 950 °C, and at the same time, H is introduced into the furnace chamber ...

Embodiment 2

[0029] Example 2 : Place the carbon fiber sample in absolute ethanol, clean it with an ultrasonic cleaner for 20 minutes, then take it out, and dry it at a low temperature at 80°C for later use;

[0030] Put the processed carbon fiber sample in the LPCVD furnace, evacuate to -0.094MPa, close the vacuum valve, and time it for 8 minutes. The index of the vacuum gauge remains unchanged, the furnace is well sealed, and the follow-up test is started;

[0031] Pass 0.3L / h of protective gas Ar, open the vacuum valve, maintain a negative pressure of -0.094MPa, and the temperature in the LPCVD furnace rises to 1100°C within 3 hours;

[0032] When the temperature rises to 1100°C, start to pass CH 4 , the flow rate is controlled at 24L / h, and the deposition time is 4h. After the preparation of the inner coating pyrolytic carbon is completed, stop the flow of CH 4 ;

[0033] Adjust the temperature of the furnace chamber, set the temperature to 1050 ° C, and at the same time pass H in...

Embodiment 3

[0036] Example 3: Place the carbon fiber sample in absolute ethanol, clean it with an ultrasonic cleaner for 25 minutes, then take it out, and dry it at 100°C for later use;

[0037] Put the processed carbon fiber sample in the LPCVD furnace, evacuate to -0.092MPa, close the vacuum valve, and time it for 10 minutes. The index of the vacuum gauge remains unchanged, the furnace is well sealed, and the follow-up test is started;

[0038] Pass 0.4L / h of protective gas Ar, open the vacuum valve, maintain a negative pressure of -0.092MPa, and the temperature in the LPCVD furnace rises to 1120°C within 3 hours;

[0039] When the temperature rises to 1120°C, start to pass CH 4 , the flow rate is controlled at 32L / h, and the deposition time is 5h. After the preparation of the inner coating pyrolytic carbon is completed, the flow of CH is stopped. 4 ;

[0040] Adjust the temperature of the furnace chamber, the temperature is set to 950 °C, and at the same time, H is introduced into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com