Anti-scald textile and preparation method thereof

A textile and anti-scald technology, applied in textiles, papermaking, fiber processing and other directions, can solve the problems of poor wear resistance, unfavorable thickness of anti-scald textiles for use or wear, and the anti-scalding effect is not lasting, and achieves the effect of good use and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

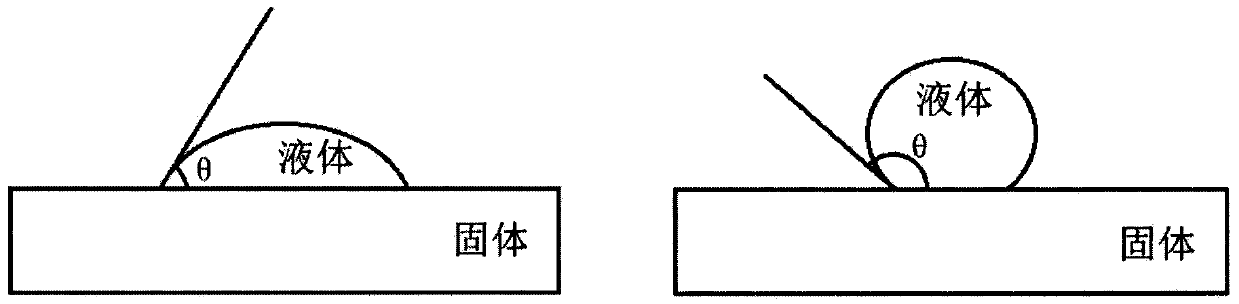

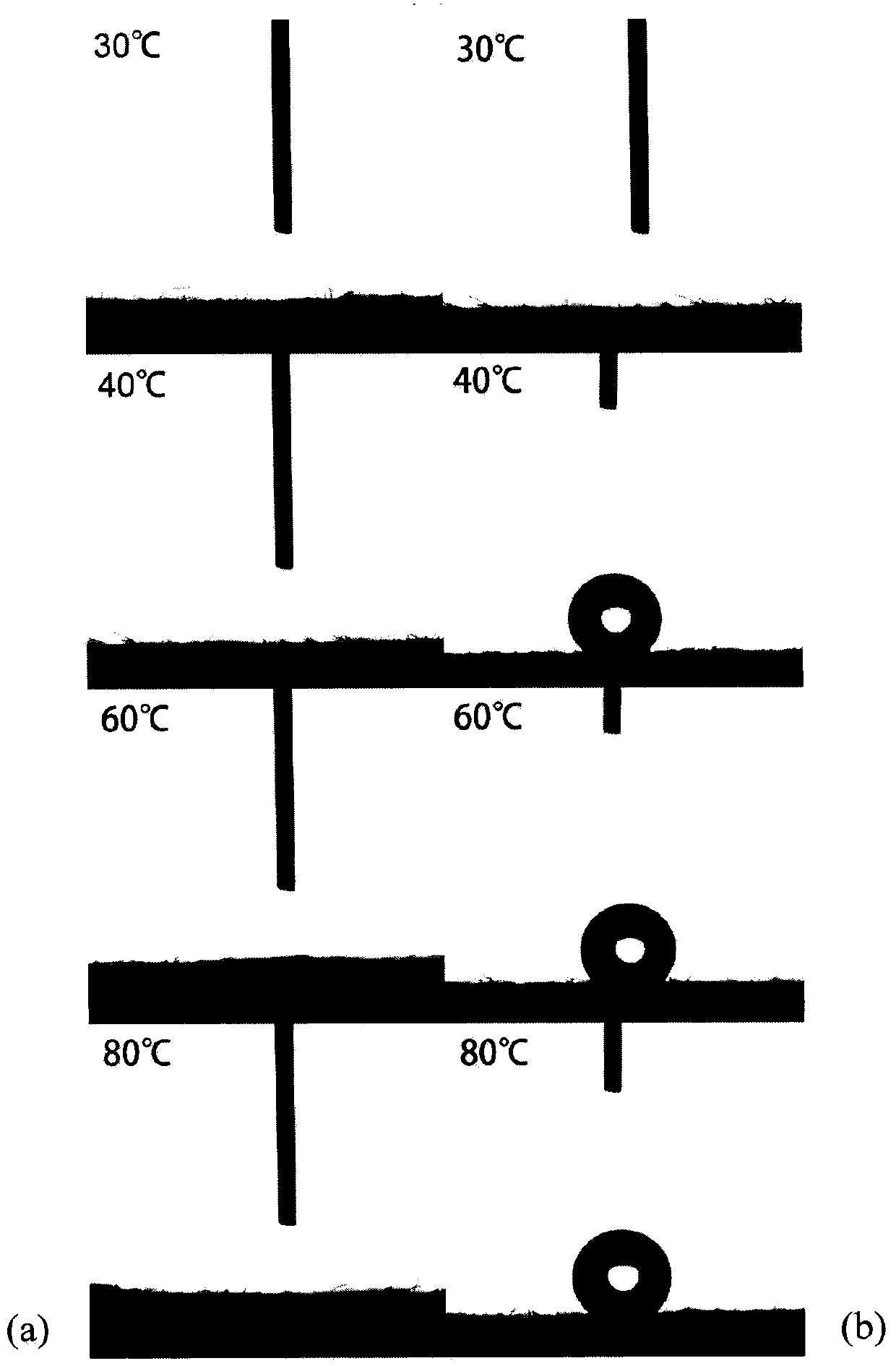

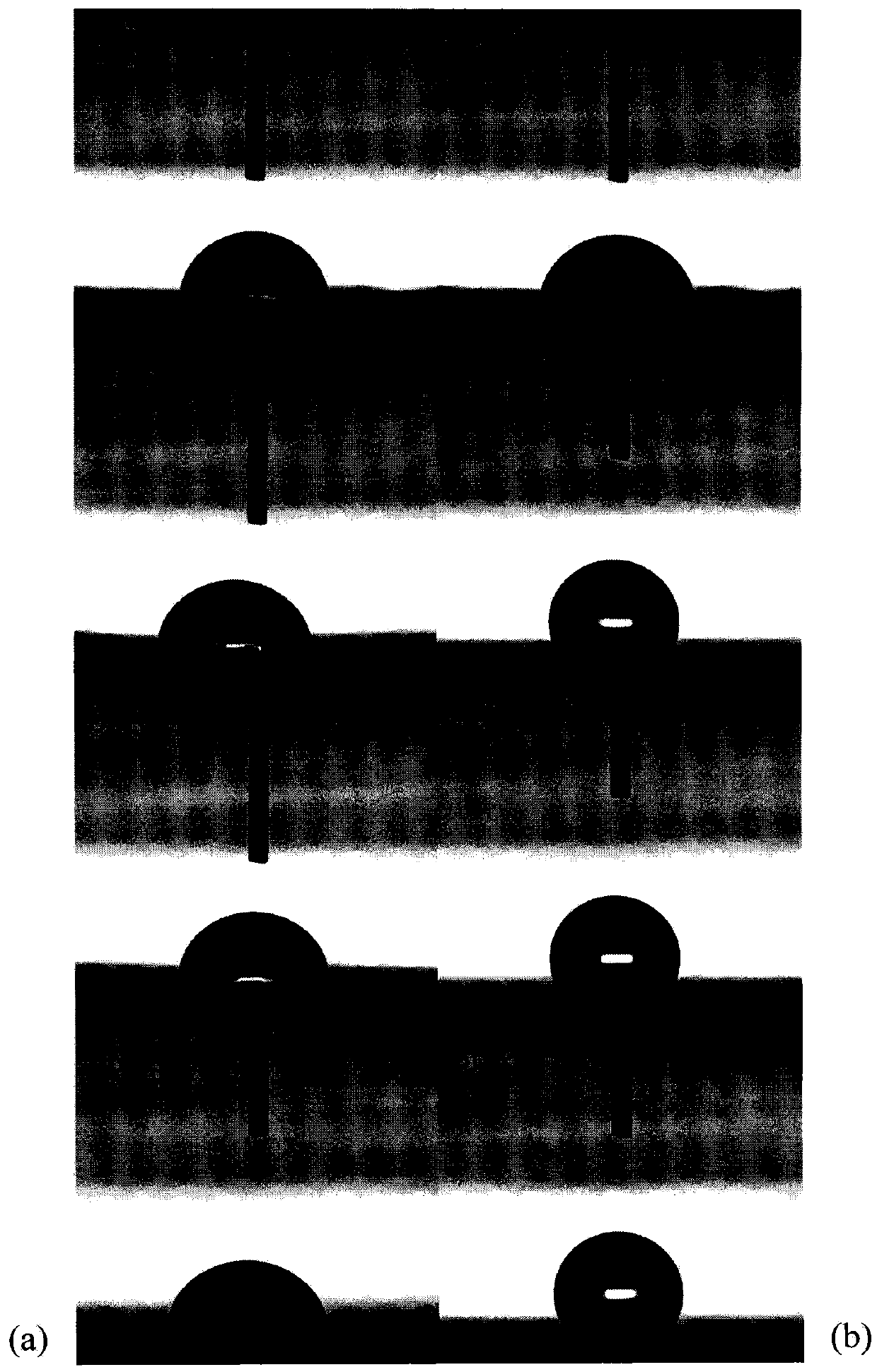

[0040] The contact angle of the cotton cloth described in Example 1 is 0°, because the hydrophilicity of the cotton cloth is excellent, and the water drop is completely spread and absorbed on the surface of the cotton cloth within 5 seconds. According to the definition of the contact angle, the contact angle of the cotton cloth is 0° °.

[0041] Example 1

[0042] Cut the cotton cloth according to the size of 10cm×15cm, after cleaning and drying, accurately weigh its mass as 1.7243g, and put the cotton cloth into the irradiation tube for later use. Prepare 100 mL of a methanol solution of N-isopropylacrylamide with a mass / volume ratio of 15 g / 100 mL (that is, 15 g of N-isopropylacrylamide per 100 mL of methanol), and add 40 mg of copper sulfate to this solution as a barrier. Polymer. Take 40mL of this solution and add it to the aforementioned irradiation tube equipped with cotton cloth. After degassing by ultrasonic vibration, vacuuming, and nitrogen gas, the irradiation tu...

Embodiment 2

[0047] Cut the nylon cloth according to the size of 10cm×15cm, after cleaning and drying, accurately weigh its mass to 0.7040g, and put the nylon cloth into the irradiation tube for later use. Prepare 100 mL of an ethanol solution of N-ethylacrylamide with a mass / volume concentration of 16.7 g / 100 mL, and add 40 mg of copper sulfate to the solution as a polymerization inhibitor. Take 40mL of this solution and add it to the aforementioned irradiation tube equipped with nylon cloth. After degassing by ultrasonic vibration, vacuuming, and nitrogen gas, the irradiation tube was sealed and placed in the cobalt source chamber for co-irradiation grafting. The absorbed dose was 30kGy. After the irradiation, the nylon cloth was taken out and purified with a Soxhlet extractor using ethanol as the purification reagent. After the purification, the anti-scald nylon cloth was dried to a constant weight, and its mass was accurately weighed to be 0.9077g. According to Formula 1, the graftin...

Embodiment 3

[0052] Cut the cotton cloth according to the size of 10cm×15cm, after cleaning and drying, accurately weigh its mass as 1.9724g, and put the cotton cloth into the irradiation tube for later use. Prepare 100 mL of an aqueous solution of N-isopropylacrylamide with a mass / volume ratio of 1 g / 100 mL, and add 40 mg of copper sulfate to the solution as a polymerization inhibitor. Take 40mL of this solution and add it to the aforementioned irradiation tube equipped with cotton cloth. After degassing by ultrasonic vibration, vacuuming, and nitrogen gas, the irradiation tube was sealed and placed in the cobalt source chamber for co-irradiation grafting. The absorbed dose was 5kGy. After the irradiation, the cotton cloth was taken out and purified in a Soxhlet extractor using methanol as the purification reagent. After the purification, the anti-scald cotton cloth was dried to constant weight, and its mass was accurately weighed to be 2.1521g. According to Formula 1, the grafting rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com