Aminosilicone durable hydrophilic potentiating agent, and preparation method and application thereof

A technology of amino silicone oil and synergist, which is applied in the field of textile chemical industry, can solve the problems of complex preparation process, poor hydrophilicity, high cost, etc., and achieve the effect of less dosage, low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

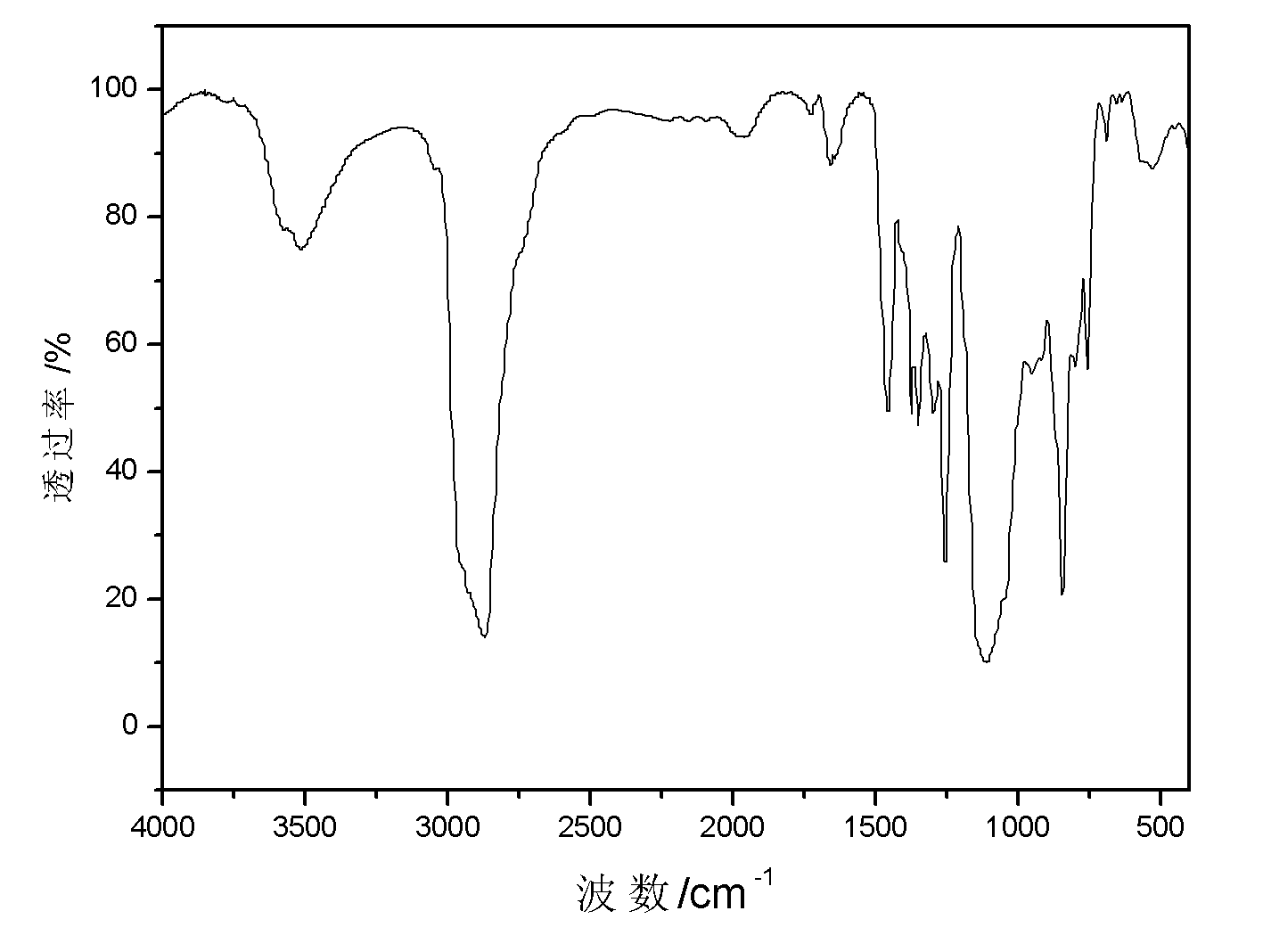

Embodiment 1

[0055] 1. Synthesis of amino silicone oil (emulsion) durable hydrophilic synergist

[0056] The mixture of 79.0g methyl hydrogen-containing silicone oil, 17.1g allyl glycidyl ether, 322.8g terminal allyl polyoxyalkylene epoxy ether and 414g allyl polyether is dropped into the reactor, and nitrogen gas And start stirring, be warming up to 85 ℃, add the isopropyl alcohol solution (mass concentration 10%) 0.238g of chloroplatinic acid, the consumption of catalyst (in terms of chloroplatinic acid) is according to 30ppm (that is 3 * 10 -5 ) was added, kept warm for 5 hours, and then the low-volatile substances were removed by distillation under reduced pressure, and the transparent liquid obtained was amino silicone oil (emulsion) durable hydrophilic synergist, and its solid content was at least 99%.

[0057] In formula I, R is -CH 3 , a=2, b=3, c=1, d=4, m=4, n=14, p=2, q=7;

[0058] The structural formula of methyl hydrogen silicone oil is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO] 2 [(...

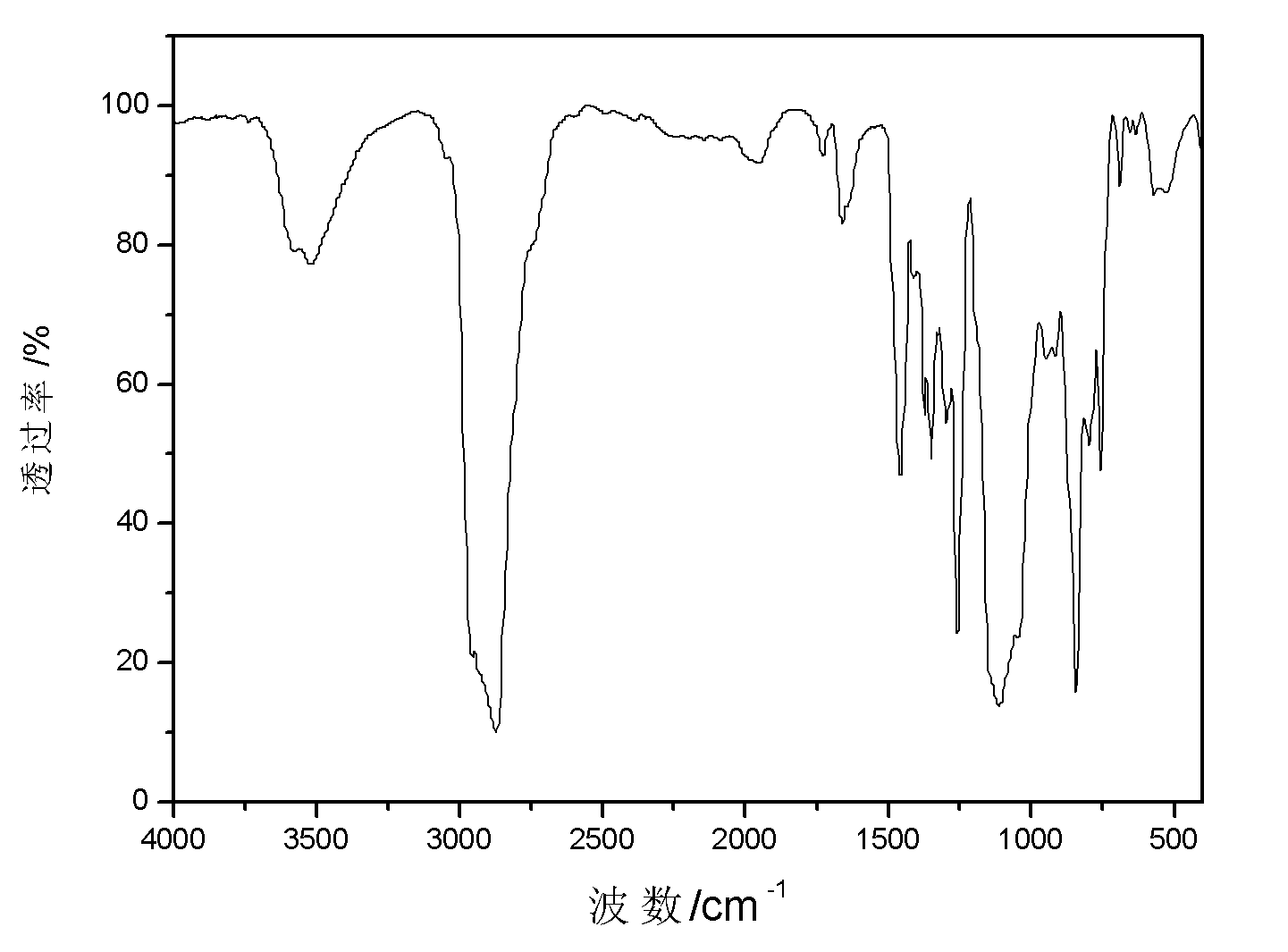

Embodiment 2

[0074] 1. Synthesis of amino silicone oil (emulsion) durable hydrophilic synergist

[0075] Put a mixture of 41.6g of methyl hydrogen silicone oil, 27.4g of allyl glycidyl ether and 50.6g of allyl polyether into the reactor, blow nitrogen and start stirring, raise the temperature to 95°C, and add platinum chloride 0.05g of absolute ethanol solution (mass concentration 12%), the consumption of catalyst (in terms of platinum chloride) is according to 50ppm (that is, 5 × 10 -5 ) added, heat preservation reaction for 7 hours, then decompressed distillation to remove low volatile substances, the transparent liquid obtained is amino silicone oil (emulsion) durable hydrophilic synergist, and its solid content is at least 98%.

[0076] In formula I, R is -CH 2 CH 2 CH 2 CH 3 , a=2, b=1, c=2, d=0, n=7, m=0;

[0077] The structural formula of methyl hydrogen silicone oil is (CH 3 ) 3 SiO[(CH 3 ) 2 SiO][(CH 3 )HSiO] 3 Si(CH 3 ) 3

[0078] The structural formula of allyl gly...

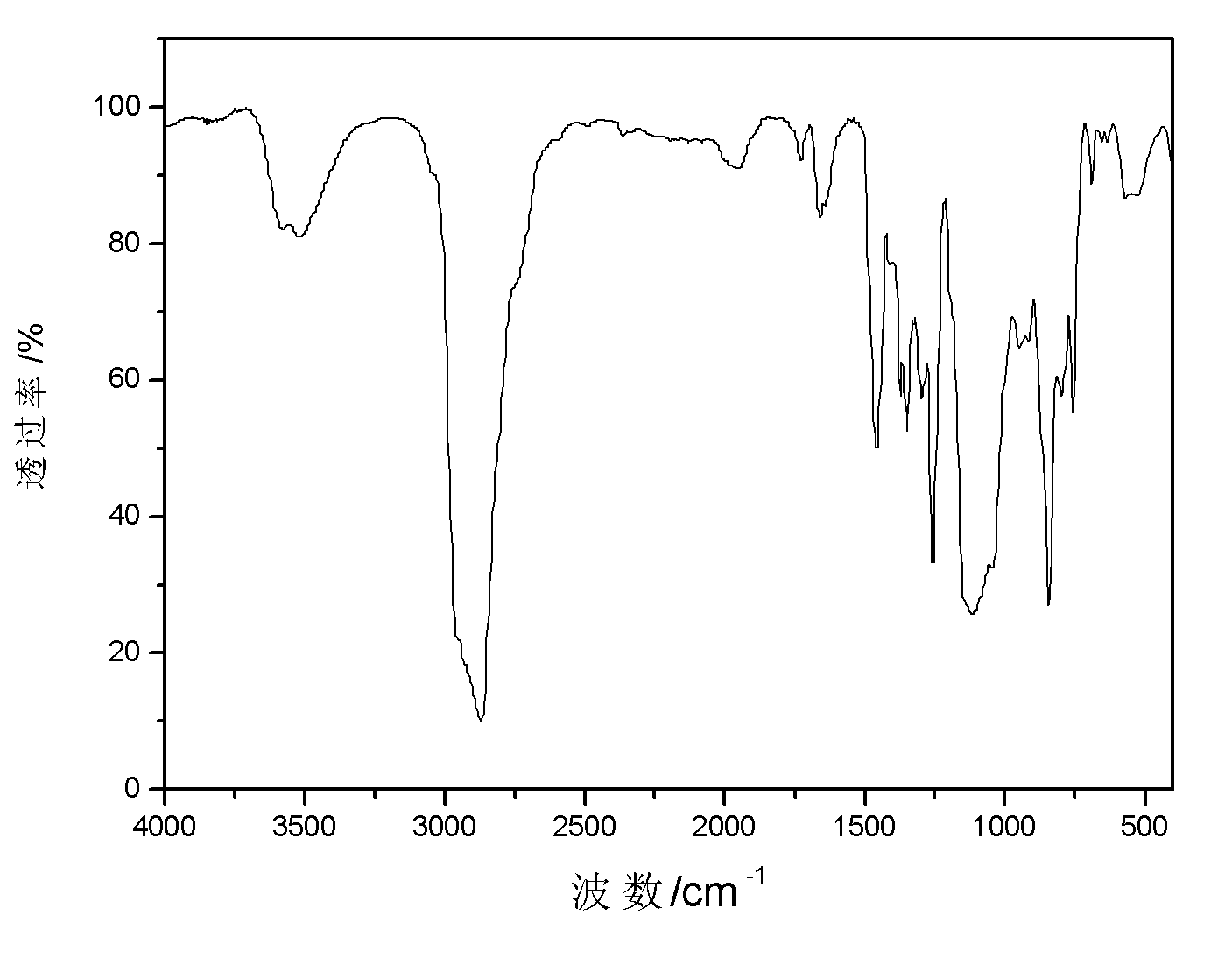

Embodiment 3

[0088] 1. Synthesis of amino silicone oil (emulsion) durable hydrophilic synergist

[0089] Put a mixture of 80.4g of methyl hydrogen-containing silicone oil, 448.8g of terminal allyl polyoxyalkylene epoxy ether and 335g of allyl polyether into the reactor, blow nitrogen and start stirring, and raise the temperature to 92°C , add 0.086g of 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex (mass concentration 15%) in dimethylsiloxane, the consumption of catalyst ( Based on 1,3-divinyl-1,1,3,3-tetramethyldisiloxane platinum complex) according to 15ppm of the total mass of reactants (ie 1.5×10 -5 ) was added, kept for 6 hours, and then the low-volatile substances were removed by distillation under reduced pressure, and the transparent liquid obtained was amino silicone oil (emulsion) durable hydrophilic synergist, and its solid content was at least 99%.

[0090] In formula I, R is -COCH 3 , a=3, b=4, c=0, d=3, m=3, n=9, p=6, q=15;

[0091] The structural formula of me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com