Anti-stripping agent, preparation method thereof, and liquid asphalt

An anti-stripping agent and liquid asphalt technology, applied in the field of asphalt additives, can solve the problems of poor anti-stripping performance of the anti-stripping agent, and achieve the effects of mild reaction conditions, simple process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

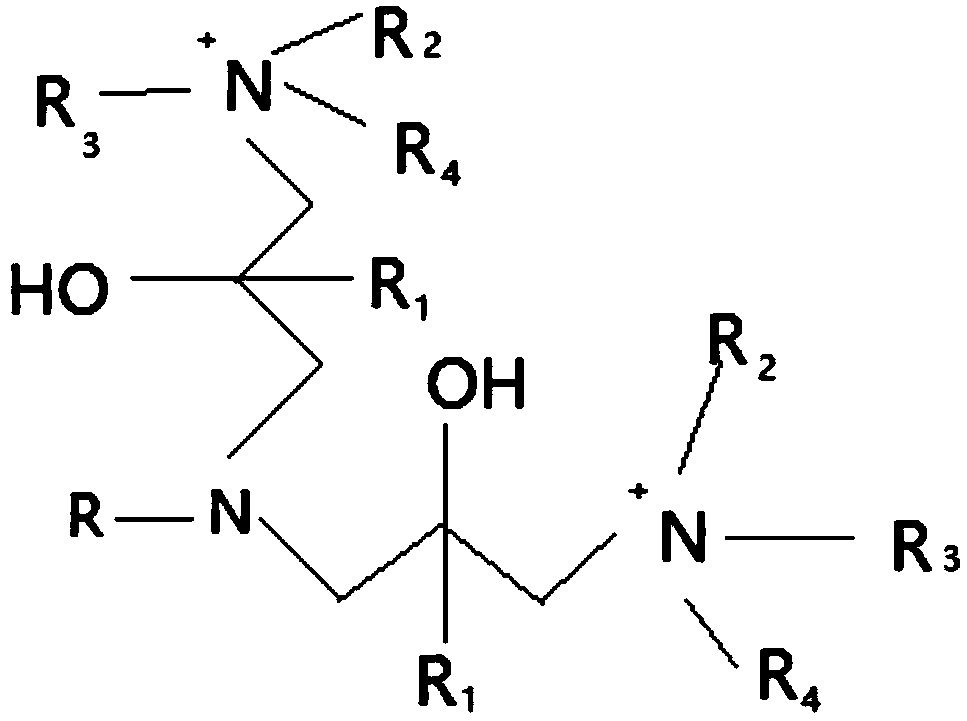

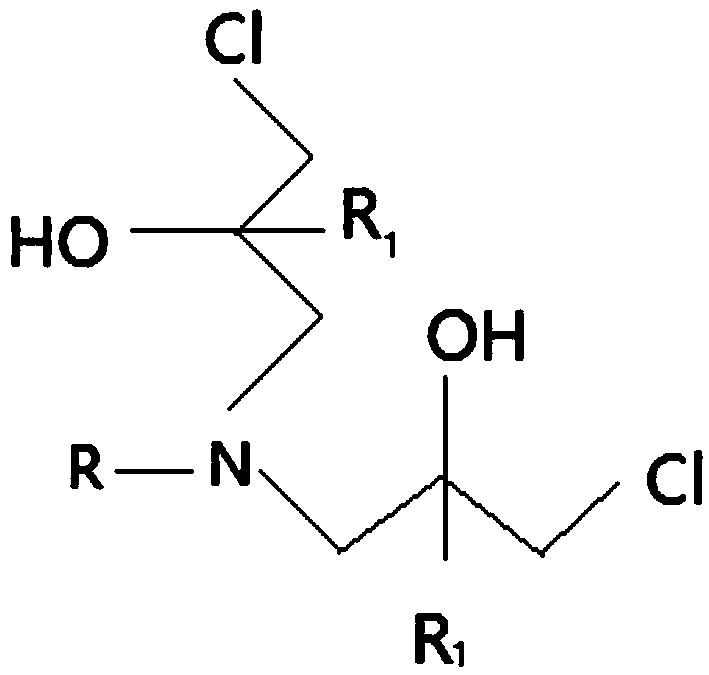

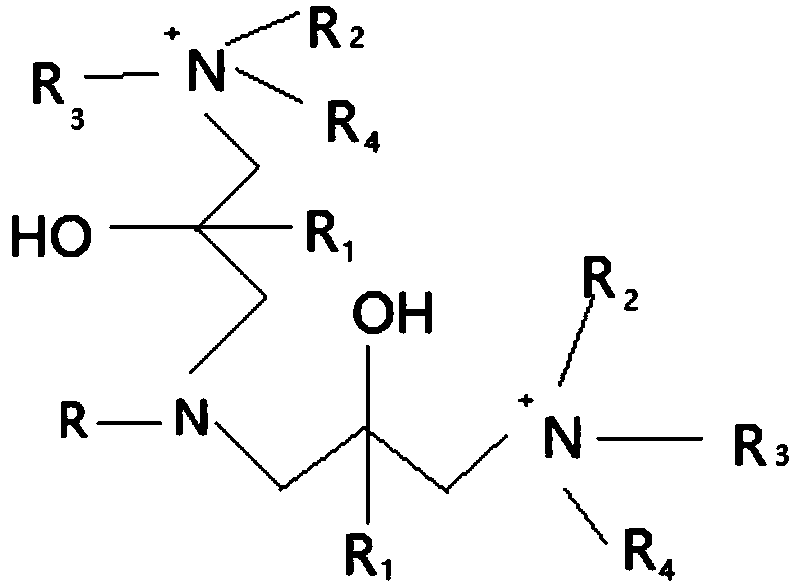

[0028] The present invention also provides a preparation method of the anti-peeling agent of the present invention, the preparation method comprises aliphatic amine and structural formula R 1 C 2 h 3 The epoxy chloroalkanes of ClO undergo a ring-opening reaction to obtain an intermediate with a structural formula of R 1 C 2 h 3 The overlapping orbitals of the epoxychloroalkanes of ClO are unstable at a specific temperature, and are easily subjected to ring-opening reactions to obtain intermediates under the attack of amines; the intermediates and structural formulas are R 2 -R 3 -R 4 -N reacts with amines to obtain anti-stripping agent. Specifically, the ring-opening reaction and the intermediate and structural formula are R 2 -R 3 -R 4 The reactions of -N amines are carried out in a solvent, and the solvent is distilled off after the reaction. The solvent is at least one selected from ethanol, methanol, toluene, ethyl acetate, cyclohexane or n-hexane. The reaction ...

Embodiment 1

[0038] Add 1 mol of octadecylamine, 2 mol of epichlorohydrin and 0.05 L of ethanol into the flask and heat to 35°C for 4 hours to obtain an intermediate product, add 2 mol of methylamine, heat up to 90°C for 10 hours and then distill off the ethanol to obtain the structural formula Anti-stripping agents as follows.

[0039]

Embodiment 2

[0041] Add 1 mol of octadecylamine, 2.1 mol of epichlorohydrin and 0.05 L of n-octane into the flask and heat to 70°C for 7.5 hours to obtain an intermediate product. Octane, for an anti-stripping agent.

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com