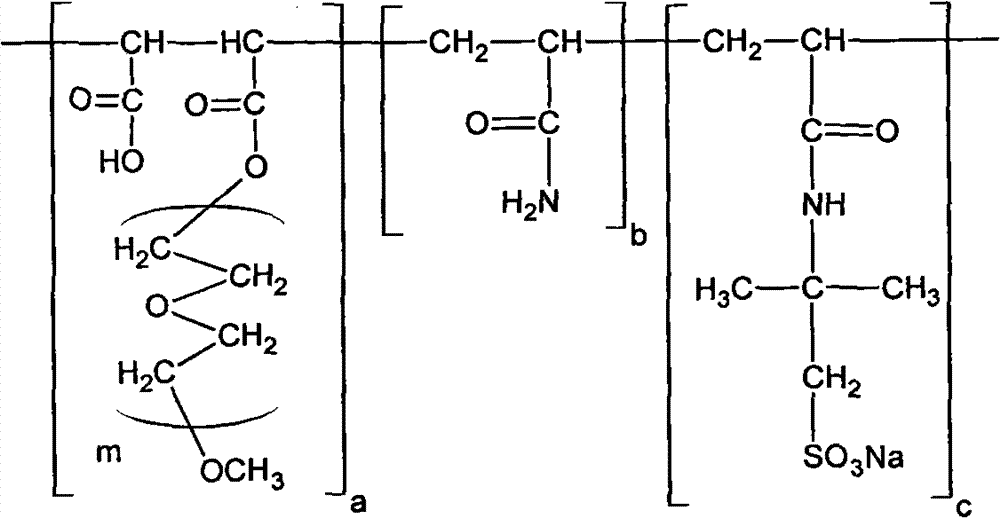

Comb-like polymer fluid loss additive for drilling fluid and preparation method thereof

A technology of comb polymer and fluid loss reducer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of poor stability of temperature and salt resistance and fluid rheological properties, and achieve low equipment requirements , strong hydration ability, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

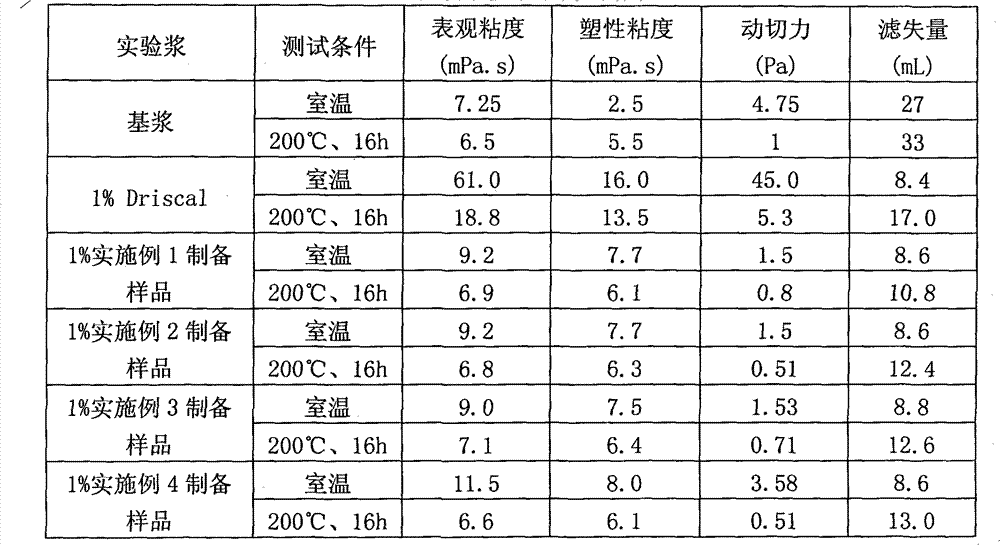

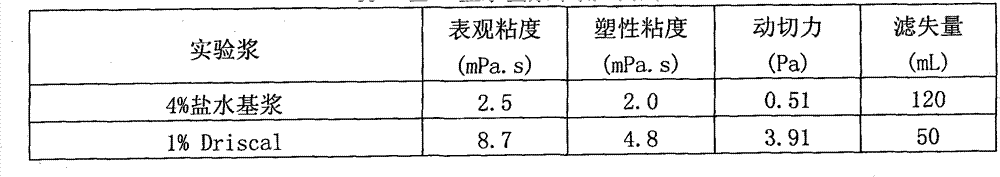

Examples

Embodiment 1

[0016] Take 17g of polyethylene glycol monomethyl ether (PEGM) and 5g of maleic anhydride (MA) in a molar ratio of 1:1.05, and put them into a reaction vessel. The molecular weight of polyethylene glycol monomethyl ether used is 350. Nitrogen was blown, and the reaction was carried out at 60° C. for 3 hours to obtain polyethylene glycol monomethyl ether maleic anhydride ester (PEGM-MA). Dissolve 8.5g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in 34g of water, and adjust the pH value to 7-8 with sodium hydroxide solution at 0-4°C. Then 23g of acrylamide (AM) and 92g of water were added, and the temperature was raised to 70°C. Add 20 g of the obtained polyethylene glycol monomethyl ether maleic anhydride ester (PEGM-MA), control the total mass concentration of monomers to 20%, 2-acrylamido-2-methylpropanesulfonic acid (AMPS), The molar ratio of acrylamide (AM) to polyethylene glycol monomethyl ether maleic anhydride (PEGM-MA) is 1:8:1.

[0017] Stir all the substances...

Embodiment 2

[0019] Take 17 g of polyethylene glycol monomethyl ether and 3.5 g of maleic anhydride in a molar ratio of 1:1.04 and put them into a reaction vessel. The molecular weight of polyethylene glycol monomethyl ether used is 500. Nitrogen was blown, and the reaction was carried out at 65° C. for 2.5 hours to obtain polyethylene glycol monomethyl ether maleic anhydride ester (PEGM-MA). Dissolve 14g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in 56g of water, and adjust the pH value to 7-8 with potassium hydroxide solution at 0-4°C. Then, 16.6 g of acrylamide (AM) and 66.4 g of water were added, and the temperature was raised to 75°C. Add 20 g of the obtained polyethylene glycol monomethyl ether maleic anhydride ester (PEGM-MA) to control the total monomer mass concentration to 20%, 2-acrylamido-2-methylpropanesulfonic acid (AMPS), The molar ratio of acrylamide (AM) to polyethylene glycol monomethyl ether maleic anhydride (PEGM-MA) is 2:7:1.

[0020] Stir all the substances...

Embodiment 3

[0022] 18 g of polyethylene glycol monomethyl ether and 2.5 g of maleic anhydride were put into the reaction vessel at a molar ratio of 1:1.06, and the molecular weight of the polyethylene glycol monomethyl ether used was 750. Nitrogen was blown, and the reaction was carried out at 68° C. for 2.5 hours to obtain polyethylene glycol monomethyl ether maleic anhydride ester (PEGM-MA). Dissolve 5.1 g of 2-acrylamido-2-methylpropanesulfonic acid (AMPS) in 20.4 g of water, and adjust the pH value to 7-8 with sodium hydroxide solution at 0-4°C. Then 14g of acrylamide (AM) and 56g of water were added, and the temperature was raised to 78°C. Add 20 g of the obtained polyethylene glycol monomethyl ether maleic anhydride ester (PEGM-MA) to control the total monomer mass concentration to 20%, 2-acrylamido-2-methylpropanesulfonic acid (AMPS), The molar ratio of acrylamide (AM) to polyethylene glycol monomethyl ether maleic anhydride (PEGM-MA) is 1:8:1.

[0023] Stir all the substances ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com