Method for assisting in igniting low-volatile coal in burning by adding oxygen

A low-volatility, low-volatility technology, applied in the field of ignition systems, can solve the problems of low-volatility, low-volatility, oxygen addition ratio, and structure without more detailed regulations, so as to optimize combustion, accelerate combustion speed, increase coal adaptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

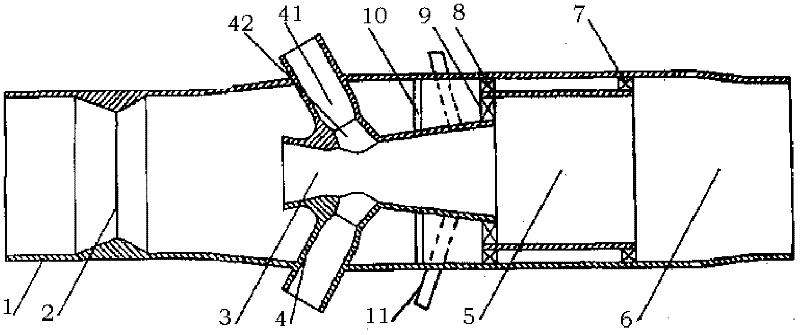

[0012] The low volatile oxygen supplemented micro-oil ignition burner used, such as figure 1 As shown, the oxygen-supplementing micro-oil ignition burner in the combustion chamber includes four parts: a pulverized coal concentrator, a pulverized coal graded combustion chamber, an oil gun and an oxygen supply pipe. A pulverized coal concentrator 2 whose inner diameter gradually decreases is arranged on the inner wall of the housing 1 near the inlet section (primary air inlet). The back of the pulverized coal concentrator 2 is connected to the third-stage combustion chamber, and the combustion chambers are connected to each other through supporting ribs. The connection and fixing of the combustion chamber 5, the second-stage combustion chamber is fixed by the second-stage rear rib 7, the second-level front rib 8 and the first-stage rear rib 9 with the first-stage combustion chamber 3, and the third-stage combustion chamber 6 The rear end is a flame-stabilizing structure whose i...

Embodiment 2

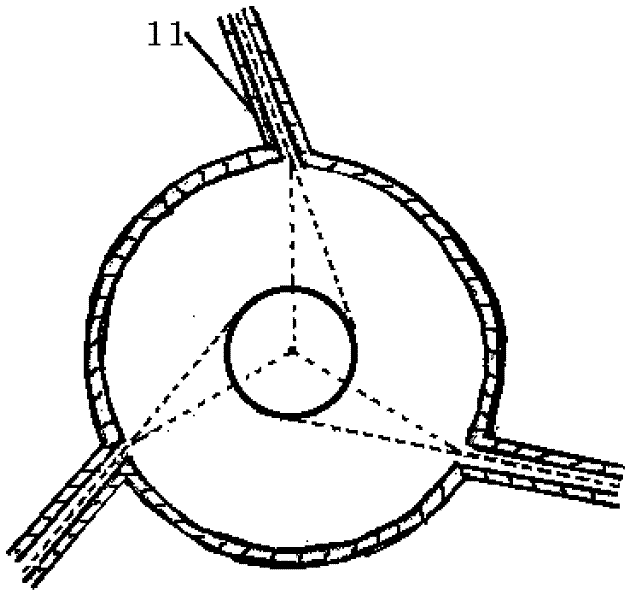

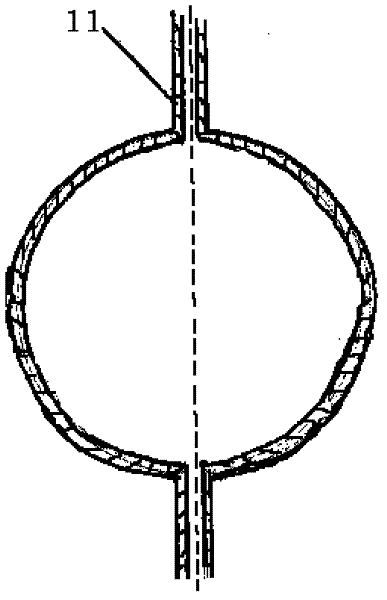

[0014] The difference between embodiment 2 and embodiment 1 is that the way of adding the oxygen supply tube is different, such as image 3 As shown in the projected cross-sectional diagram of the middle oxygen supply pipe entering the inlet of the burner, the oxygen supply pipe in Example 2 uses two oxygen supply pipes, and the oxygen supply pipe enters the burner in a hedging manner. The two oxygen supply pipes in Embodiment 2 can also be arranged in a radial and tangential direction. When arranged tangentially, the included angle between the axis of the oxygen supply pipe and the normal of this point is 10-20°. Other aspects are basically consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com