Preparation method of zinc electrode used for zinc-air battery

A zinc-air battery and zinc electrode technology, applied in the field of electrochemical power sources, can solve the problems of battery discharge performance degradation, alkali creep and leakage, etc., and achieve the effect of prolonging the service life and storage period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

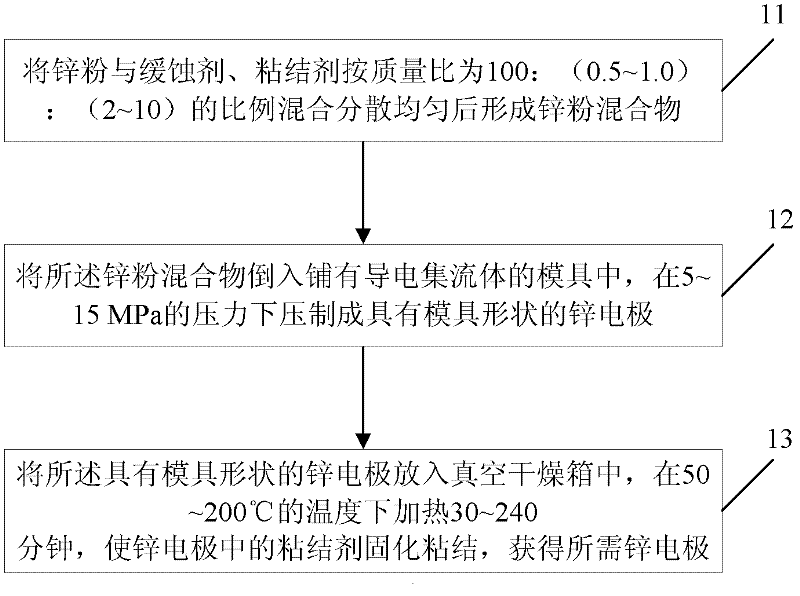

Method used

Image

Examples

Embodiment 1

[0034] First take 0.2g In(OH) 3 , 0.2g CdO, 1g carboxymethyl cellulose (CMC) and 50g of active zinc powder for alkaline batteries are mixed, and dispersed evenly after being stirred by a mixer. The resulting zinc powder mixture was poured into a mold, dry-pressed under a pressure of 5 MPa to form a zinc electrode, then placed in a vacuum oven and heated at 100°C for 60 minutes, and cooled to room temperature with the furnace to prepare a zinc electrode.

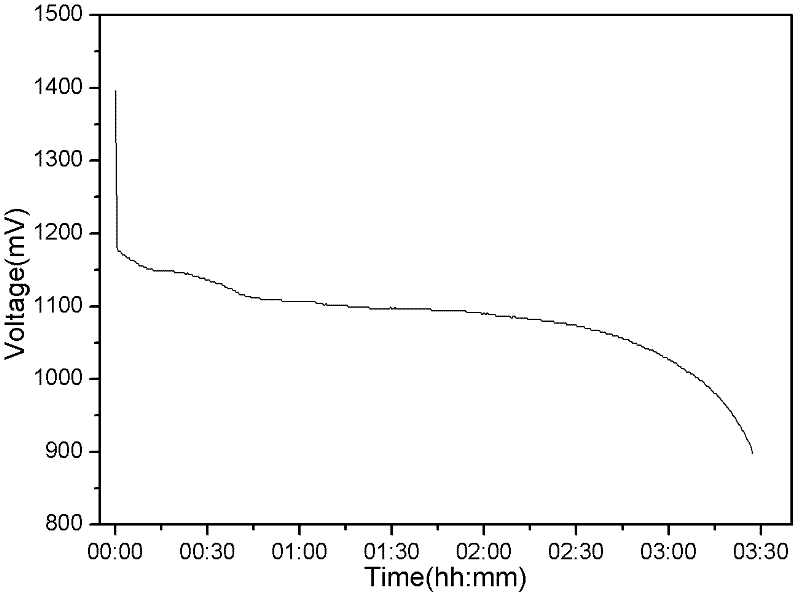

[0035] Then, the prepared zinc electrode and air electrode were assembled into a zinc-air battery. When in use, inject 35% KOH electrolyte solution through the liquid injection port on the top of the battery case, and let it stand for 5 minutes until the electrolyte diffuses evenly, then conduct a constant current discharge test with a current of 8A, set the termination voltage to 0.9V, and the battery discharge capacity to be 27.7Ah with an average voltage of 1.08V. Finally, the 8A constant current discharge curve of the z...

Embodiment 2

[0037] First take 0.5g In 2 o 3 , 3g carboxymethyl cellulose (CMC), 3g polytetrafluoroethylene (PTFE) are mixed with 100g alkaline battery active zinc powder, disperse evenly after being stirred by a mixer. The resulting zinc powder mixture was poured into a mold, dry-pressed under a pressure of 10 MPa to form a zinc electrode, then placed in a vacuum oven and heated at 150°C for 30 minutes, and cooled with the furnace to prepare a zinc electrode.

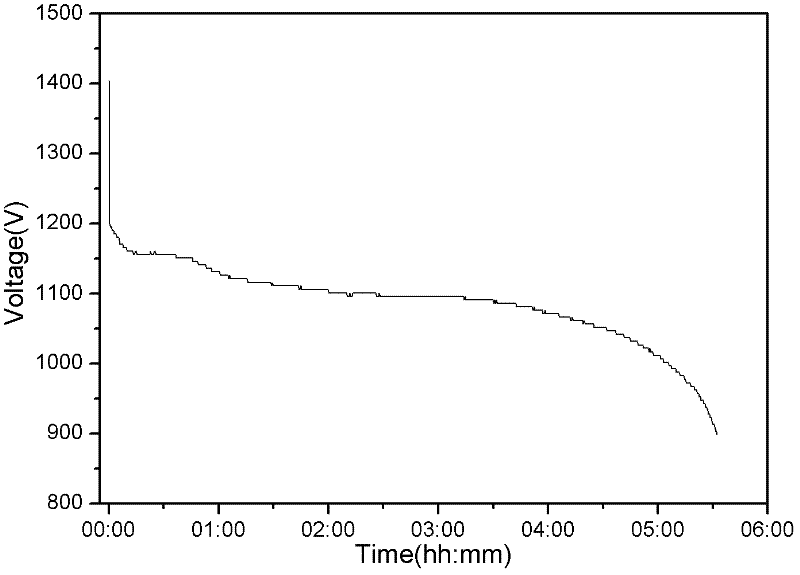

[0038]Then, the prepared zinc electrode and air electrode were assembled into a zinc-air battery. When in use, inject 35% KOH electrolyte solution through the liquid injection port on the top of the battery case, and let it stand for 5 minutes until the electrolyte diffuses evenly, then conduct a constant current discharge test with a current of 10A, set the termination voltage to 0.9V, and the battery discharge capacity to be 55.3Ah with an average voltage of 1.09V. Finally, the 10A constant current discharge curve of the zinc-...

Embodiment 3

[0040] First take 0.6g In(OH) 3 , 0.3g PbO, 4g carboxymethylcellulose sodium (CMC-Na), 4g polytetrafluoroethylene (PTFE) and 175g alkaline battery active zinc powder are mixed, and dispersed evenly after being stirred by a mixer. The resulting zinc powder mixture was poured into a mold, dry-pressed under a pressure of 15 MPa to form a zinc electrode, then placed in a vacuum oven and heated at 120°C for 45 minutes, and cooled with the furnace to prepare a zinc electrode.

[0041] Then, the prepared zinc electrode and air electrode were assembled into a zinc-air battery. When in use, inject 35% KOH electrolyte solution through the liquid injection port on the top of the battery case, and let it stand for 5 minutes until the electrolyte diffuses evenly, then conduct a constant current discharge test with a current of 15A, set the termination voltage to 0.9V, and the battery discharge capacity to be 99.1Ah, the average voltage is 1.12V. The final 15A constant current discharge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com