Method for forming three-dimensional micro spiral channel inside quartz glass by using femto-second laser

A technology of quartz glass and femtosecond laser, which is applied in the direction of manufacturing tools, laser welding equipment, welding equipment, etc., can solve the problems of poor transparency, complicated production, and large heat generation of silicon-based materials, and achieve strong light transmission ability and biological The effect of good affinity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

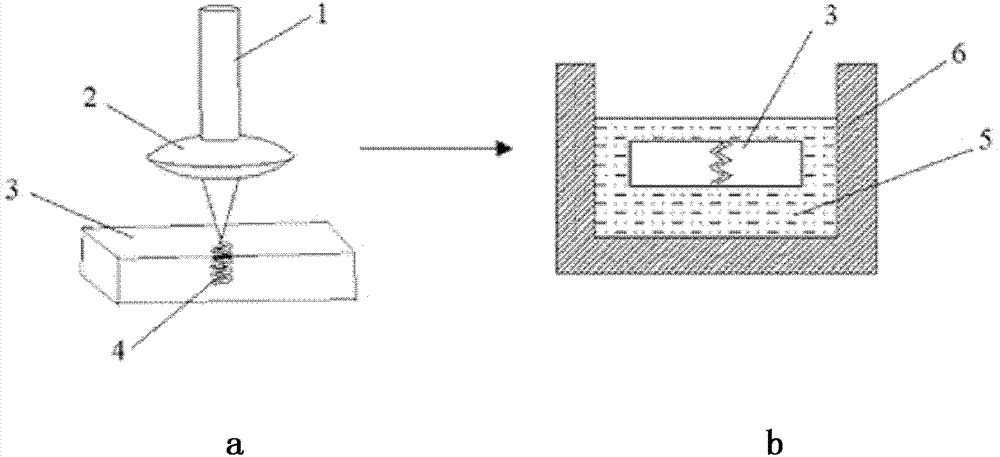

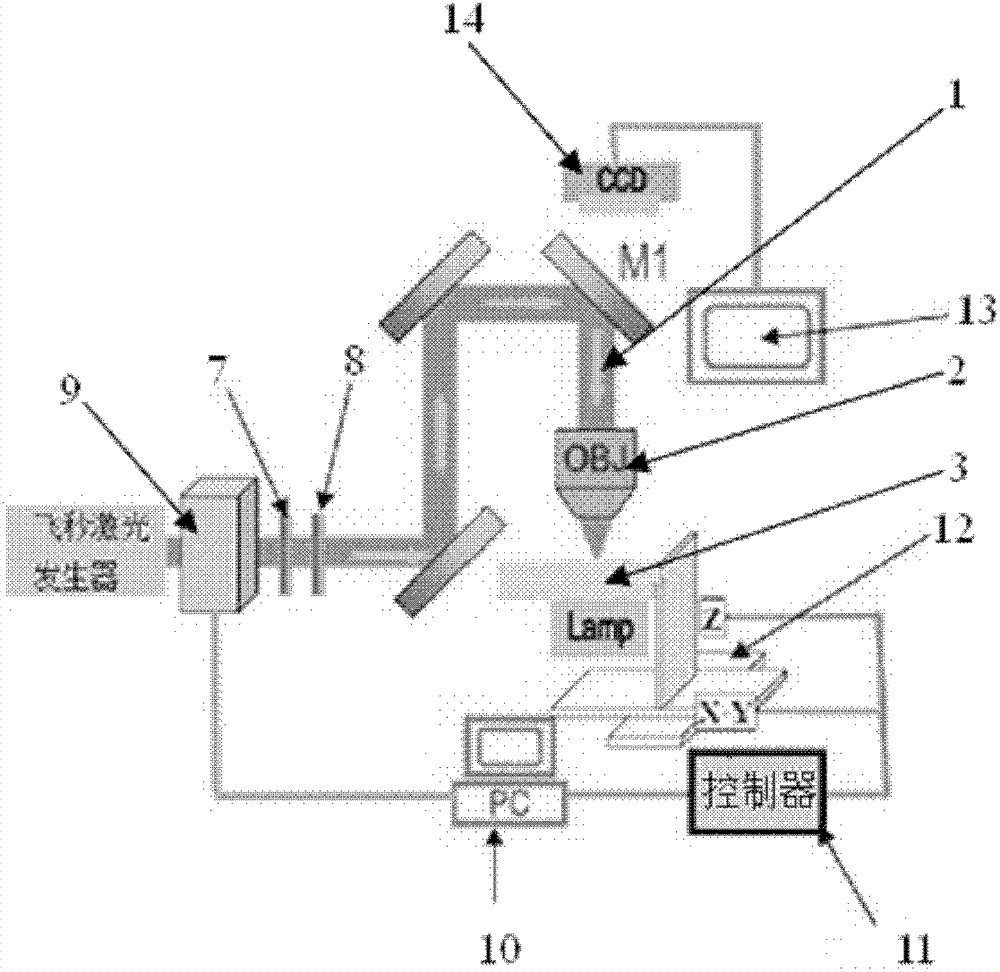

[0027] This embodiment includes the following steps.

[0028] Step 1. The femtosecond laser beam passes through the attenuator, polarizer and lens installed on the optical path to gather the focus on the lower surface of the quartz glass. The quartz glass is fixed on the three-dimensional precision table, and the movement of the three-dimensional precision table is controlled to make the femtosecond laser beam The focus is scanned from bottom to top inside the quartz glass to get the required micro spiral trace profile.

[0029] The thickness of the quartz glass is L=1200um, the femtosecond laser focusing adopts 100 times lens, the numerical aperture of the lens is 0.9, and the required micro-spiral trajectory contour radius R=60um, the scanning speed of the femtosecond laser is equal to 10um / s .

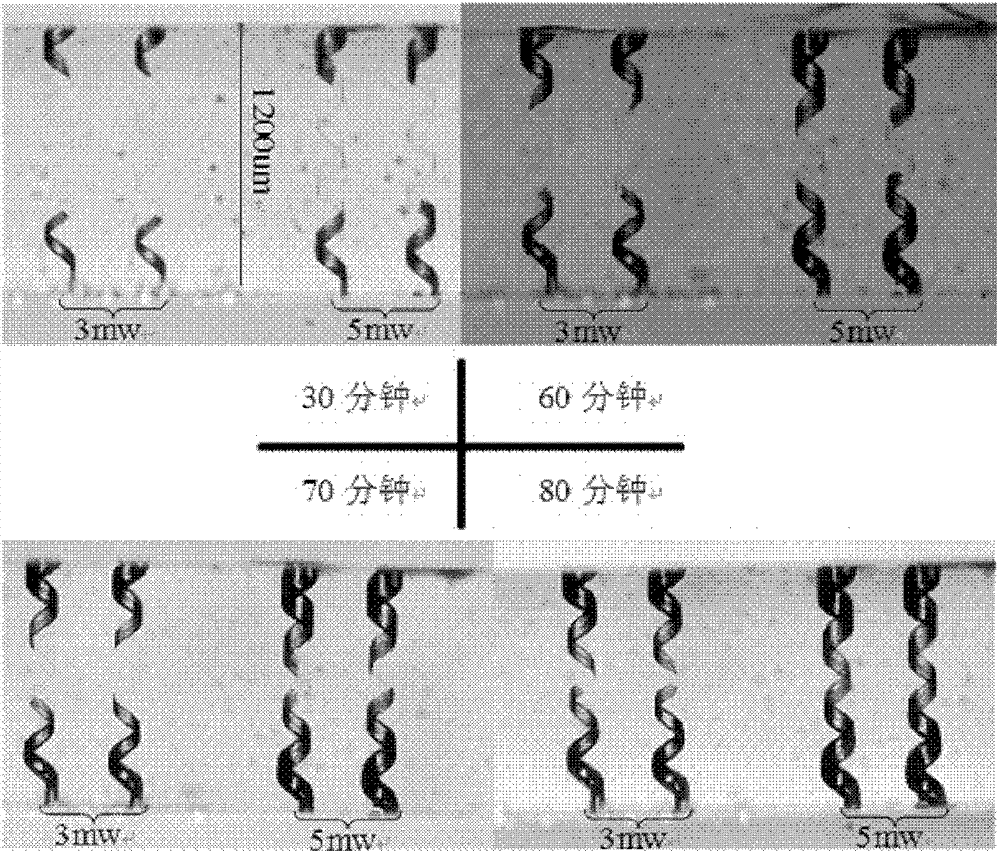

[0030] Step 2: Immerse the scanned quartz glass substrate in a hydrofluoric acid solution with a mass concentration of 10%, and place it in an ultrasonic environment at a temperature of 6...

Embodiment 2

[0033] This embodiment includes the following steps:

[0034] Step 1. The femtosecond laser beam passes through the attenuator, polarizer and lens installed on the optical path to gather the focus on the lower surface of the quartz glass. The quartz glass is fixed on the three-dimensional precision table, and the movement of the three-dimensional precision table is controlled to make the femtosecond laser beam The focus is on the inside of the quartz glass to scan the required micro-spiral trajectory profile from bottom to top;

[0035] The thickness of the quartz glass is L=1200um, the femtosecond laser focusing adopts 100 times lens, the numerical aperture of the lens is 0.9, and the power of the femtosecond laser beam passing through the attenuator, polarizer and lens is 3 milliwatts. The radius of the micro spiral track profile is R=100um, and the scanning speed of the femtosecond laser is equal to 10um / s.

[0036] Step 2: Immerse the scanned quartz glass substrates in hydrofluo...

Embodiment 3

[0039] This embodiment includes the following steps:

[0040] Step 1. The femtosecond laser beam passes through the attenuator, polarizer and lens installed on the optical path to gather the focus on the lower surface of the quartz glass. The quartz glass is fixed on the three-dimensional precision table, and the movement of the three-dimensional precision table is controlled to make the femtosecond laser beam The focus is on the inside of the quartz glass to scan the required micro-spiral trajectory profile from bottom to top;

[0041] The thickness of the quartz glass is L=1200um, the femtosecond laser focusing adopts 100 times lens, the numerical aperture of the lens is 0.9, and the required micro-spiral trajectory contour radius R=60um, the scanning speed of the femtosecond laser is equal to 10um / s .

[0042] Step 2: Immerse the scanned quartz glass substrate in a hydrofluoric acid solution with a concentration of 10%, and place it in an ultrasonic environment at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com