Transparent oxyfluoride tellurite glass

A technology of tellurate glass and oxyfluoride, which is applied in the field of optical glass materials, can solve the problems of easy crystallization and phase separation of glass, poor thermal stability, poor thermal stability, etc., and achieve high transition temperature and low maximum sound The effect of sub-energy and low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

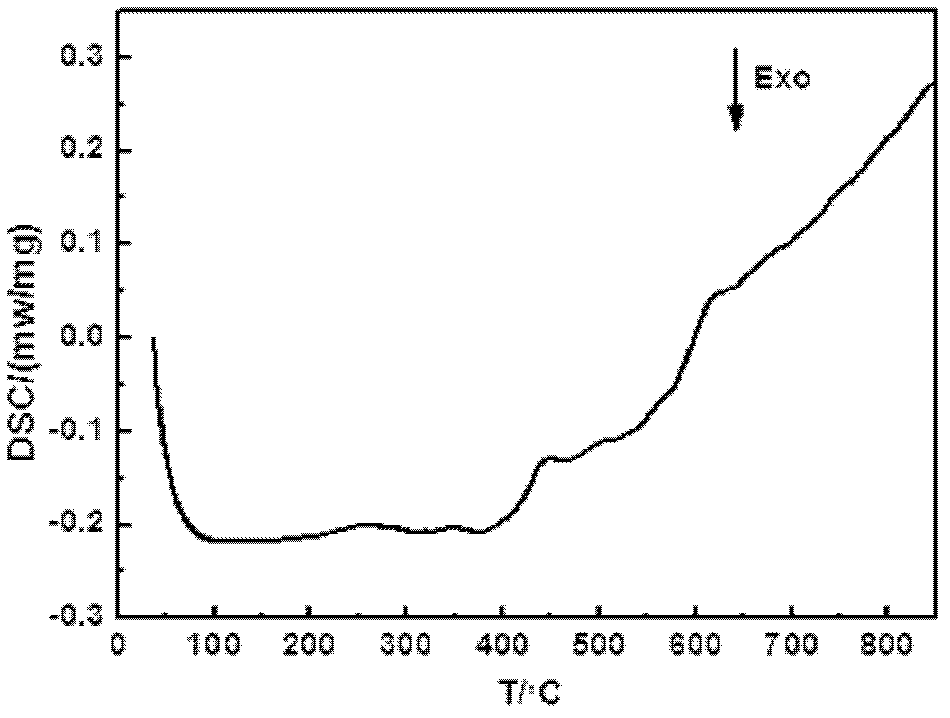

Image

Examples

Embodiment 1

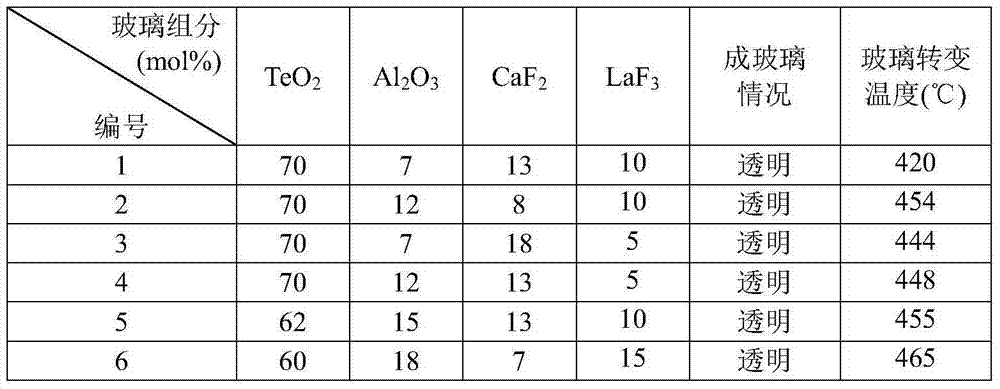

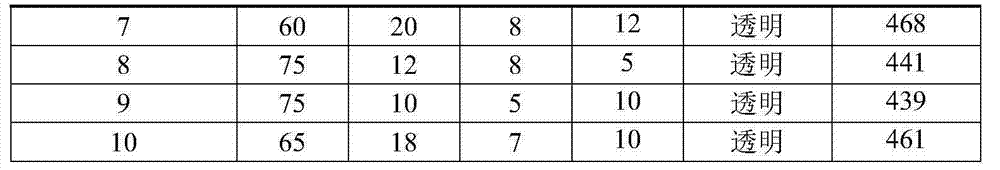

[0021] A kind of transparent oxyfluoride tellurate glass, select the raw material formula of transparent oxyfluoride tellurate glass according to the first group in Table 1, that is, 70TeO 2 -7Al 2 o 3 -13CaF 2 -10LaF 3 (mol%). Its preparation method is:

[0022] 1. According to the composition of the above-mentioned new transparent oxyfluoride tellurate glass, select the raw material formula of transparent oxyfluoride tellurate glass, among which TeO 2 and LaF 3 For high-purity raw materials, CaF 2 and Al 2 o 3 For the analysis of pure raw materials, each raw material was weighed according to the stoichiometric ratio.

[0023] 2. After uniformly mixing the raw materials in step 1 in a planetary ball mill for 30 minutes, pour them into a platinum crucible and cover it.

[0024] 3. Put the covered platinum crucible in step 2 into a silicon carbon rod resistance furnace for melting, the melting temperature is 850°C, keep it warm for 30 minutes, then raise it to 50°C, a...

Embodiment 2

[0029] A kind of transparent oxyfluoride tellurate glass, according to the second group in Table 1, select the raw material formula of transparent oxyfluoride tellurate glass, that is, 70TeO 2 -12Al 2 o 3 -8CaF 2 -10LaF 3 (mol%). Its preparation method is:

[0030] 1. According to the composition of the above-mentioned new transparent oxyfluoride tellurate glass, select the raw material formula of transparent oxyfluoride tellurate glass, among which TeO 2 and LaF 3 For high-purity raw materials, CaF 2 and Al 2 o 3 For the analysis of pure raw materials, each raw material was weighed according to the stoichiometric ratio.

[0031] 2. Mix the raw materials in step 1 evenly in a planetary ball mill for 30 minutes, then pour into a platinum crucible and cover it.

[0032] 3. Put the covered platinum crucible in step 2 into a silicon carbon rod resistance furnace for melting, the melting temperature is 900°C, keep it warm for 30 minutes, then raise it to 50°C, and keep it...

Embodiment 3

[0036] A transparent oxyfluoride tellurate glass, according to the third group in Table 1, select the transparent oxyfluoride tellurate glass raw material formula, namely 70TeO 2 -7Al 2 o 3 -18CaF 2 -5LaF 3 (mol%). Its preparation method is:

[0037] 1. According to the composition of the above-mentioned new transparent oxyfluoride tellurate glass, select the raw material formula of transparent oxyfluoride tellurate glass, among which TeO 2 and LaF 3 For high-purity raw materials, CaF 2 and Al 2 o 3 For the analysis of pure raw materials, each raw material was weighed according to the stoichiometric ratio.

[0038] 2. Mix the raw materials in step 1 evenly in a planetary ball mill for 30 minutes, then pour into a platinum crucible and cover it.

[0039]3. Put the covered platinum crucible in step 2 into a silicon carbon rod resistance furnace for melting, the melting temperature is 850°C, keep it warm for 30 minutes, then raise it to 50°C, and keep it warm for 30 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com