Conductive ceramic, method for preparing same and application for same

A technology of conductive ceramics and conductive agents, applied in the field of ceramics, can solve problems such as unreasonable relationship, low specific energy, and difficult breakthroughs in lead-based batteries, and achieve the effect of strong corrosion resistance and strong adsorption force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

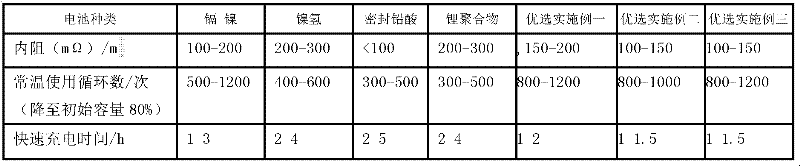

[0045] As a preferred embodiment of the present invention one, by weight, the storage battery grid produced with the conductive ceramics of the present invention contains 15 parts of conductive agent, 70 parts of ceramic composite material and 15 parts of dielectric material, and is then used for storage battery. After testing, The internal resistance of the battery is 150-200 (mΩ) / m, the number of cycles at room temperature is 800-1200 times, and the fast charging time is 1-2 hours.

Embodiment 2

[0046] As a preferred embodiment of the present invention two, by weight, the storage battery grid produced with the conductive ceramic of the present invention contains 20 parts of conductive agent, 65 parts of ceramic composite material and 15 parts of dielectric material, and then used for storage battery, after testing, The internal resistance of the battery is 100-150 (mΩ) / m, the number of cycles at room temperature is 800-1000, and the fast charging time is 1-1.5 hours.

Embodiment 3

[0047] As the third preferred embodiment of the present invention, by weight, the storage battery grid produced by the conductive ceramics of the present invention contains 20 parts of conductive agent, 70 parts of ceramic composite material and 10 parts of dielectric material, and is then used for storage battery. After testing, The internal resistance of the battery is 100-150 (mΩ) / m, the number of cycles at room temperature is 800-1200 times, and the fast charging time is 1-1.5 hours.

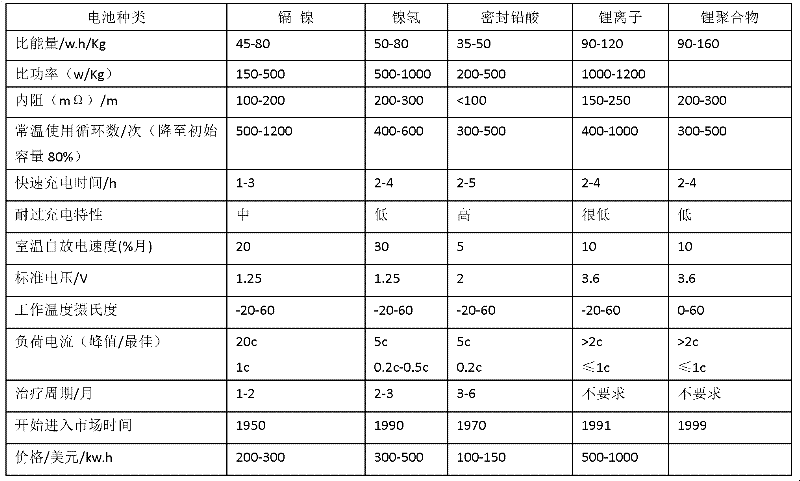

[0048] The accumulator manufactured by the accumulator grid produced by three preferred embodiments of the present invention is compared with other types with the same capacity accumulator as shown in the table below:

[0049]

[0050] It can be seen from the above table that compared with other types of storage batteries with the same capacity, the performance of the storage battery using the conductive ceramic of the present invention in terms of internal resistance, cycle times at norma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com