High-purity capsaicin compound refining crystallization method

A technology of capsaicin and compounds, which is applied in the field of crystallization, can solve problems such as complex equipment and steps, difficulty in industrial production, and resin regeneration, and achieve the effects of low production cost, no discharge of three wastes, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

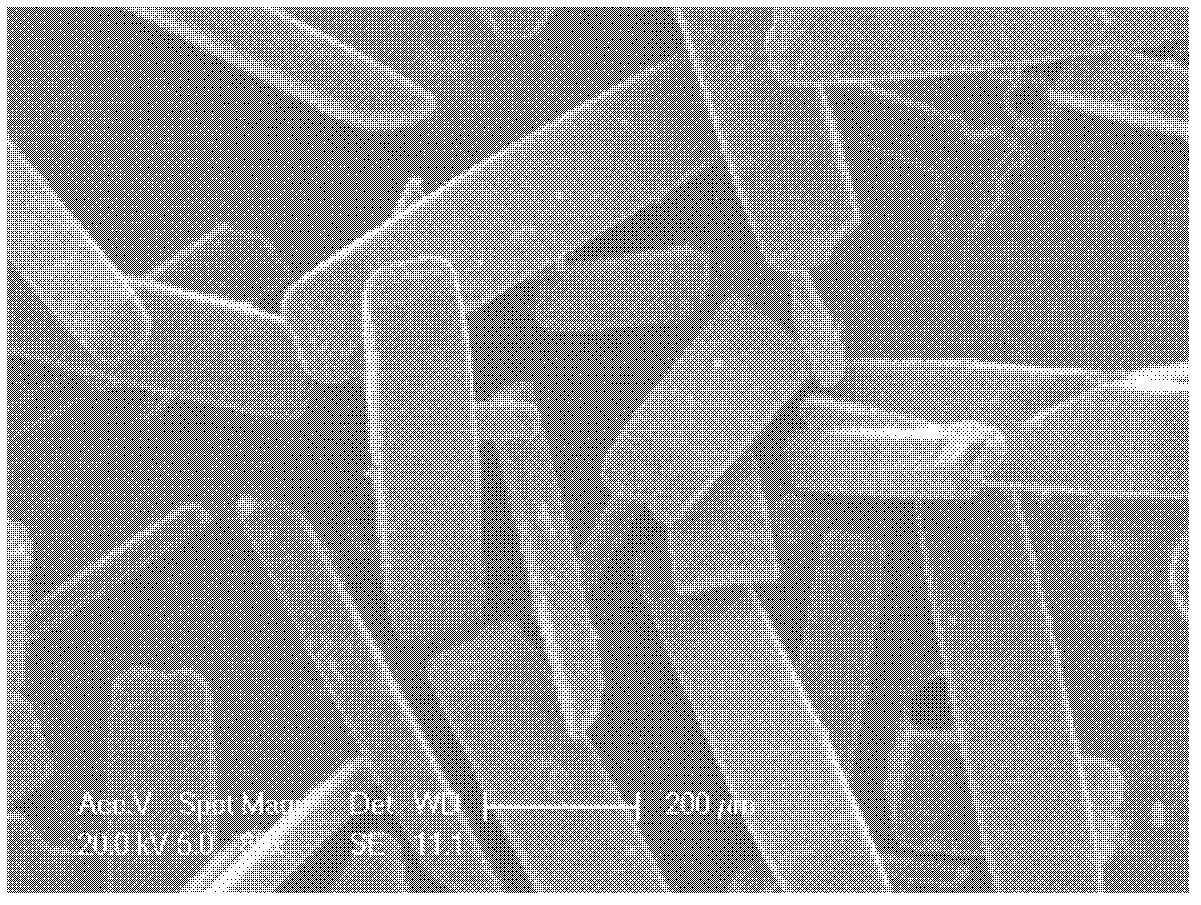

[0018] Crystallization to prepare high-purity natural capsaicin compound crystals:

[0019] Add 4.00 g of crude natural capsaicin compounds with a mass purity of 50% into a mixed solvent of 200 mL of petroleum ether and 800 mL of n-butyl ether, stir and dissolve at a constant temperature of 45 ° C, and filter after continuous stirring for 40 minutes; the filtrate is transferred to a crystallizer Inside, carry out cooling and crystallization under stirring, the stirring speed is 100r / min, after 6 hours, the temperature drops to 10°C; after the crystallization is complete, filter and separate, wash the crystals with a mixed solvent, and ventilate and dry the crystals at 55°C for 4 hours , to obtain white high-purity natural capsaicin compound crystal product 1.47g.

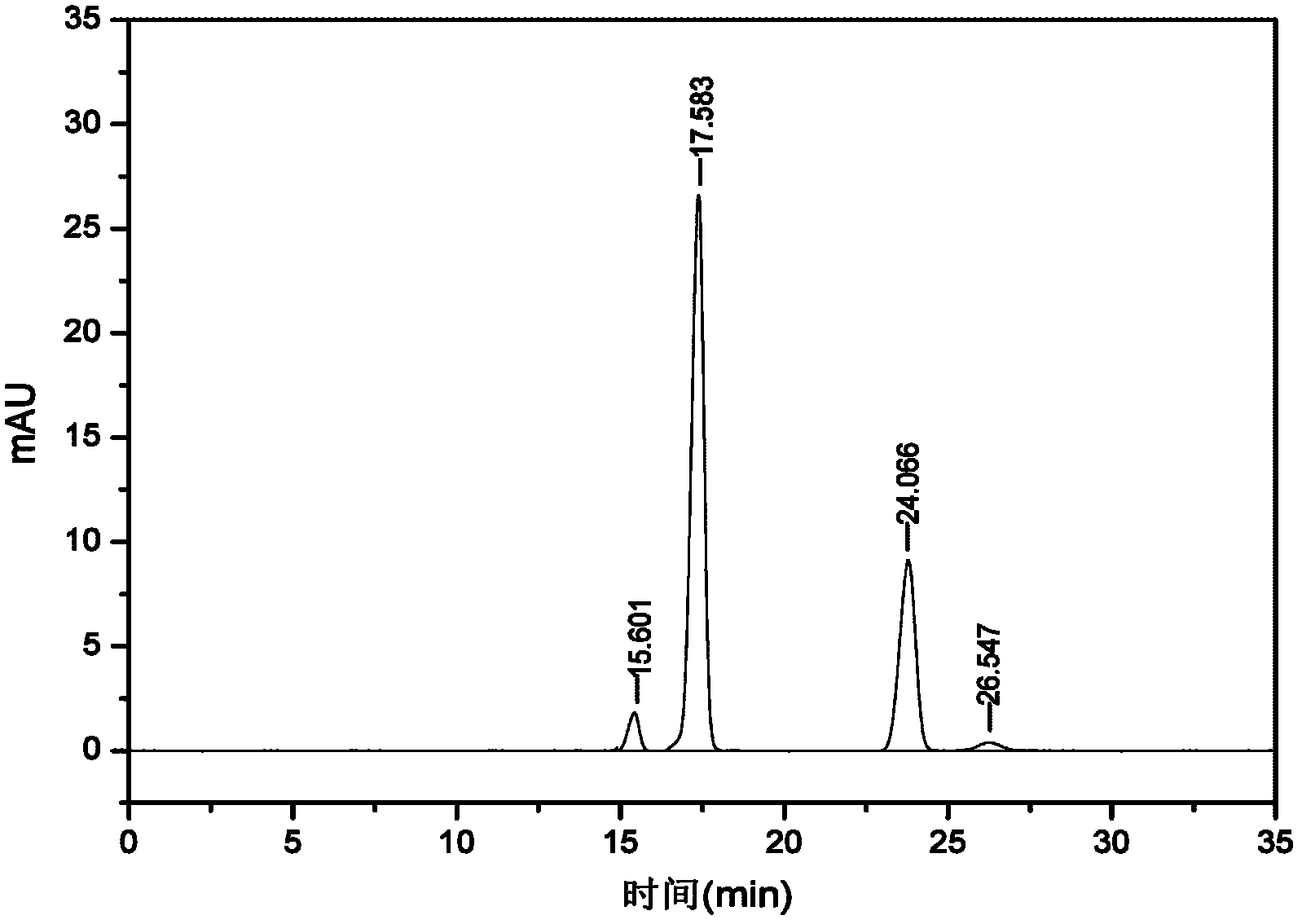

[0020] HPLC detection of total capsaicin content: 99.80%

[0021] HPLC detection capsaicin monomer content: 67.17%

[0022] The sum of the content of capsaicin monomer and dihydrocapsaicin detected by HPLC is 91.0...

Embodiment 2

[0025] Crystallization to prepare high-purity natural capsaicin compound crystals:

[0026] 25.00g mass purity is that 80% raw material natural capsaicin compound crude product is added in the mixed solvent of 2000mL sherwood oil and 500mL ethanol, stirs and dissolves under the constant temperature of 40 ℃, filters after continuous stirring 60 minutes; Filtrate moves in the crystallizer, Cool and crystallize under stirring, the stirring speed is 300r / min, and the temperature drops to -10°C after 10 hours; after the crystallization is complete, filter and separate, wash the crystals with a mixed solvent, and vacuum dry the crystals at 55°C for 3 hours. Obtained 15.58g of white high-purity natural capsaicin compound crystal product.

[0027] HPLC detection of total capsaicin content: 99.2%

[0028] HPLC detection capsaicin monomer content: 70.21%

[0029] The sum of the content of capsaicin monomer and dihydrocapsaicin detected by HPLC is 92.03%

[0030] Product quality yield...

Embodiment 3

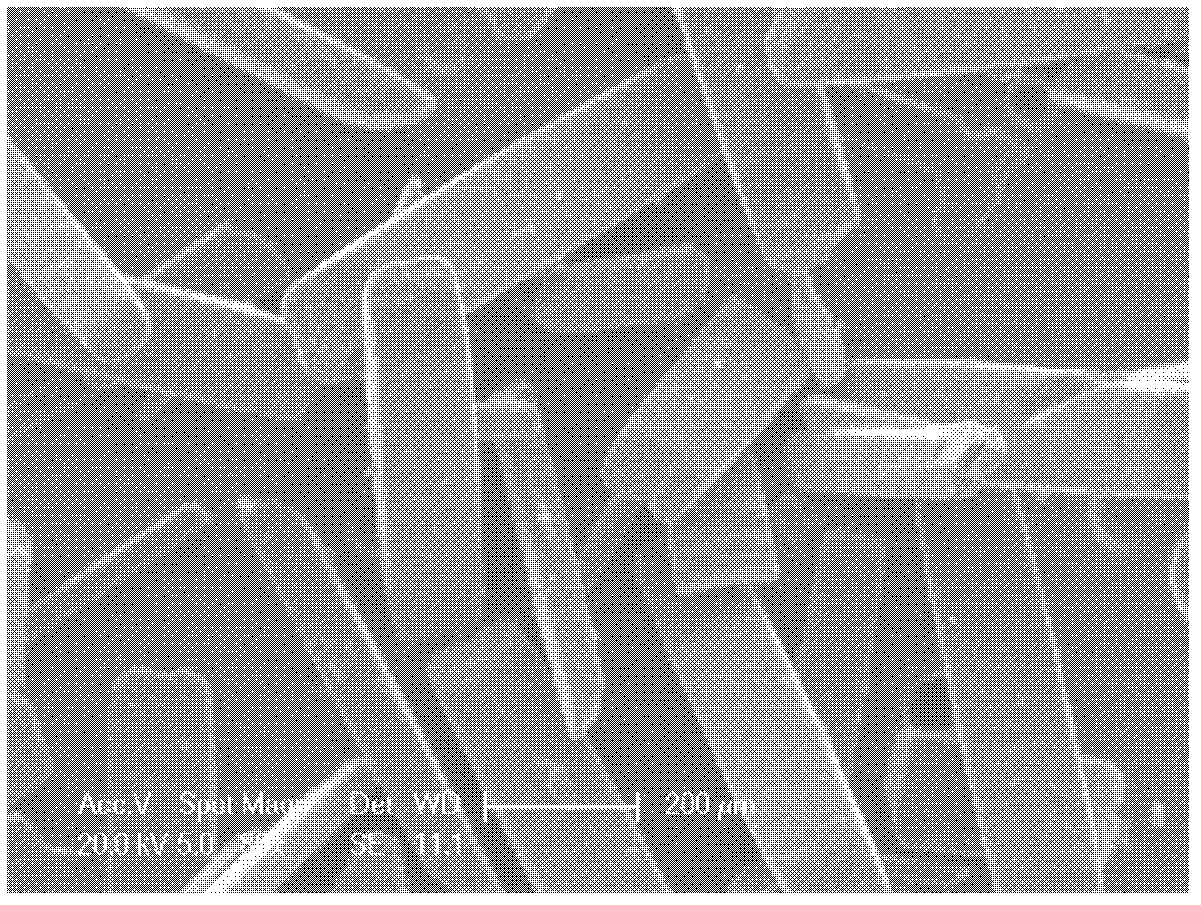

[0032] Crystallization to prepare high-purity natural capsaicin compound crystals:

[0033] Add 2.96g of crude natural capsaicin compounds with a mass purity of 60% into a mixed solvent of 250mL of n-hexane and 250mL of isopropyl ether, stir and dissolve at a constant temperature of 60°C, and filter after continuous stirring for 10 minutes; the filtrate is transferred to a crystallizer Inside, carry out cooling crystallization under stirring, the stirring speed is 500r / min, and after 1 hour the temperature drops to 25°C; after the crystallization is complete, filter and separate, wash the crystals with a mixed solvent, and ventilate and dry the crystals at 45°C for 4.5 hours , to obtain white high-purity natural capsaicin compound crystal product 1.57g.

[0034] HPLC detection of total capsaicin content: 99.54%

[0035] HPLC detection capsaicin monomer content: 68.91%

[0036] The sum of the content of capsaicin monomer and dihydrocapsaicin detected by HPLC is 90.05%

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com