Feed granules and preparation method of feed granules

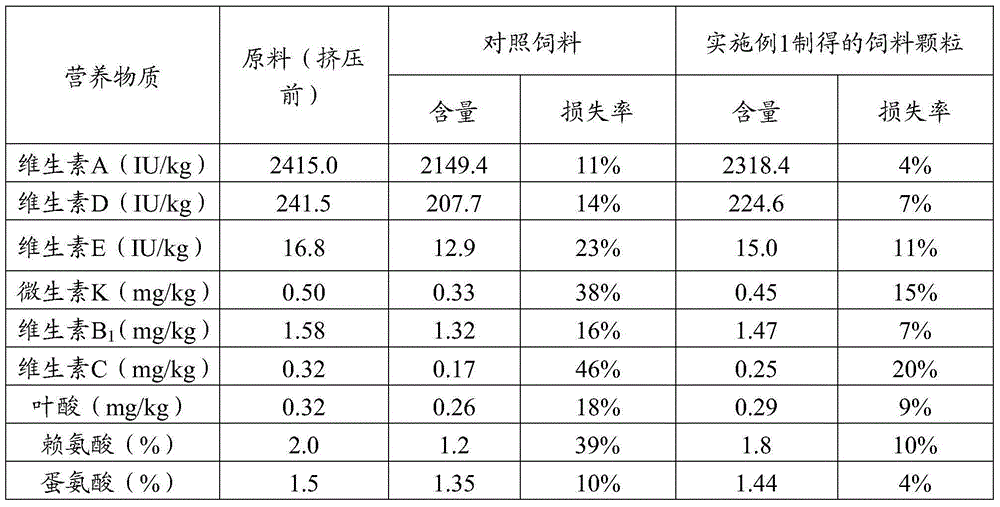

A technology of feed pellets and pellets, which is applied in the field of feed pellets and its preparation, can solve the problems of loss of feed active substances, increase of pellet pulverization rate, loss of nutrients, etc., to reduce the reduction of nutritional value, reduce the loss of nutrients, and ensure healthy growth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation of embodiment 1 feed pellet

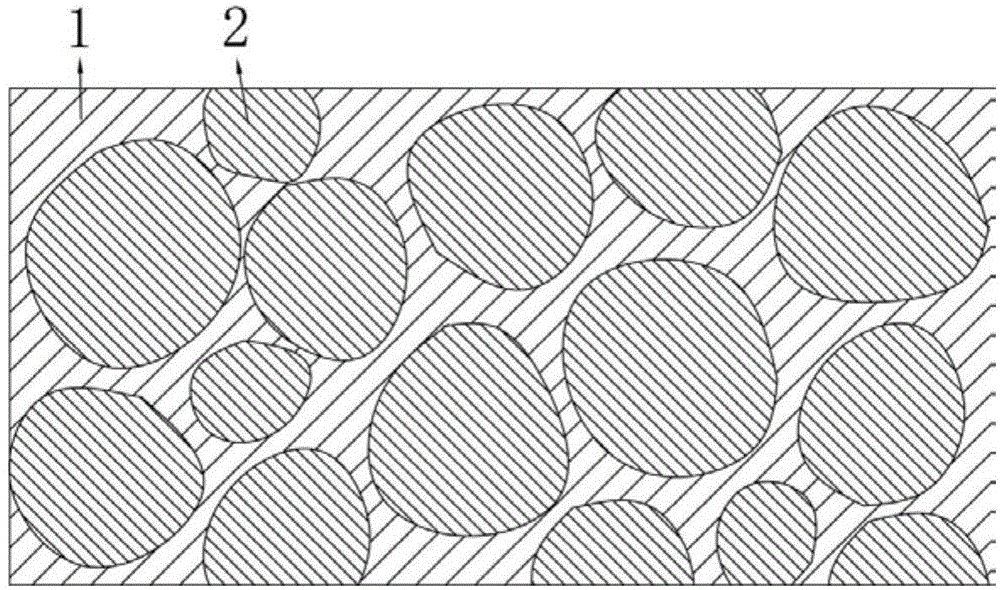

[0056] First mix 14.5kg of corn gluten powder, 15.5kg of fish meal, 22.3kg of soybean meal, 0.5kg of multivitamins, 2.5kg of minerals, 0.5kg of lysine, and 0.2kg of methionine, and prepare it at room temperature (10°C-35°C). Particles (spheres) with an average particle size of 10mm are used as the dispersed phase, and its main components are protein, fiber, amino acid, vitamin, etc.

[0057] Mix 30.0kg of flour, 1.0kg of soybean oil, 1.0kg of fish oil, and 2.0kg of phospholipid to form a continuous phase whose main components are sugar, starch, fat and other components.

[0058] The above-prepared dispersed phase and continuous phase were mixed evenly, and 10 kg of water was added to adjust the water content, and then extruded and granulated through a ring die at 130° C. to obtain feed granules. The feed granules have a columnar structure, a circular cross section, an axial length of 100 mm, and a radial average diameter of...

Embodiment 2

[0082] The preparation of embodiment 2 feed pellets

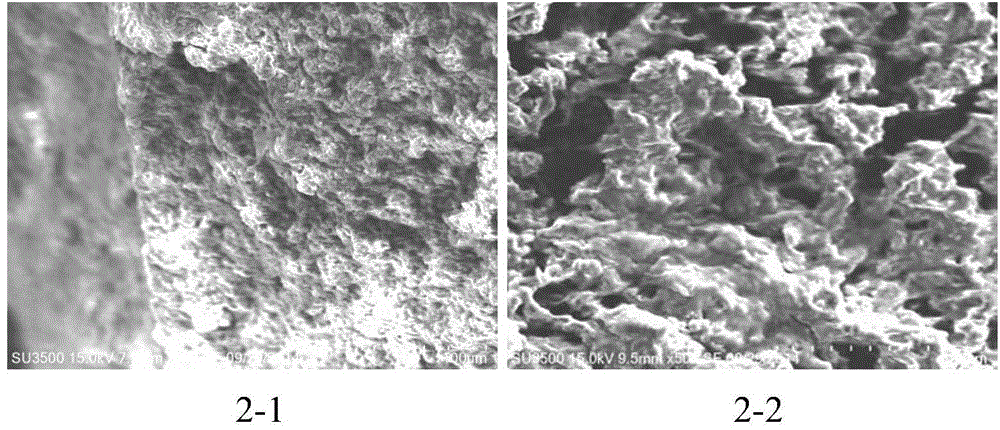

[0083] First mix 20kg of rice bran, 16kg of bran, and 5kg of glucose evenly, and prepare 5mm particles (spheres) at room temperature (10°C-35°C) as dispersed phase 2-1, whose main components are starch, reducing sugar, etc.

[0084] Mix 0.1 kg of lysine, 0.1 kg of methionine, 0.6 kg of multivitamins and 1 kg of bone meal, and prepare 1 mm particles (spheres) at room temperature (10°C-35°C) as the dispersed phase 2-2.

[0085] Mix 3kg of fish meal, 20kg of bean cake, 15kg of peanut cake, and 10kg of corn gluten powder to prepare a continuous phase whose main components are protein, amino acid, fiber, etc.

[0086] The dispersed phase 2-1, dispersed phase 2-2 and continuous phase prepared above were mixed evenly, and 10 kg of water was added to adjust the water content, and pelletized by twin-screw extrusion at 140° C. to obtain feed pellets. The feed granules have a flake structure, a pentagram-shaped cross section, an axia...

Embodiment 3

[0089] The preparation of embodiment 3 feed pellets

[0090] Mix 15kg of fish meal, 10kg of meat and bone meal, 3kg of brewer’s yeast, and 5kg of corn gluten powder evenly, and prepare 5mm particles (polyhedron, frustum or cylinder) at low temperature (36°C-75°C) as dispersed phase 2-1. Its main component is protein.

[0091] Mix 2.5kg pine needle powder, 6.85kg black locust leaf powder, 6kg seaweed powder, 0.15kg vitamin C phosphate, and 0.5kg choline chloride evenly, and prepare 2mm particles at room temperature (10°C-35°C) as the dispersed phase 2-2, its main components are fiber, polysaccharides, trace elements and so on.

[0092] Mix 15kg of dehulled soybean meal and 10kg of rapeseed meal evenly as dispersed phase 2-3.

[0093] Mix 25kg of flour and 1kg of soybean oil evenly to make particles with an average particle size of less than 1mm as the continuous phase, and its main components are starch, oil, etc.

[0094] The dispersed phase 2-1, dispersed phase 2-2, disperse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com