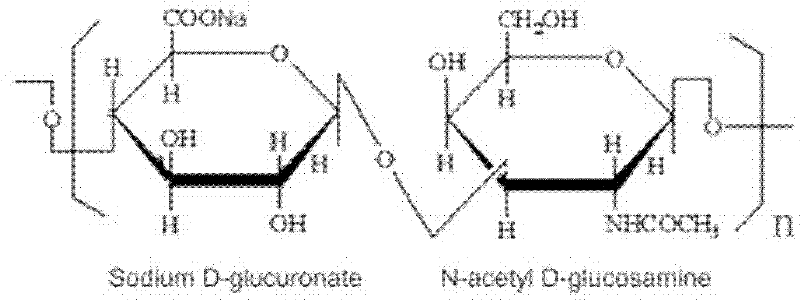

Method for carrying out secondary complexing precipitation and purification on sodium hyaluronate

A technology of complexation precipitation and sodium hyaluronate, which is applied in the field of sodium hyaluronate secondary complexation precipitation purification, can solve the problems of incomplete complexation precipitation, viscous supernatant, and high ionic strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

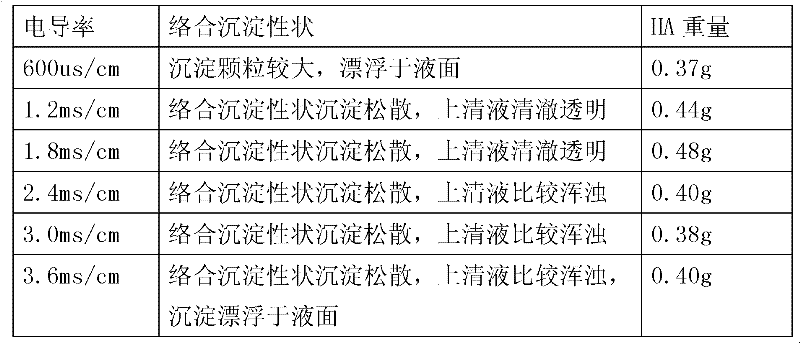

[0025] Sodium hyaluronate was prepared by the existing extraction method, and 2400ml of the filtrate was taken from the cockscomb enzymatic hydrolysis solution once activated carbon was adsorbed and filtered, and divided into 6 parts on average, numbered A, B, C, D, E, F respectively. Use purified water or sodium chloride to adjust the conductivity of the filtrate to the following: A-600us / cm, B-1.2ms / cm, C-1.8ms / cm, D-2.4ms / cm, E-3.0ms / cm, F-3.6ms / cm, respectively take 1.6g of CPC and add appropriate amount of water to dissolve, then complex and precipitate with the above 6 filtrates under the same conditions, collect the precipitate after complexation, and prepare 260ml of 0.4mol / L solution The complexed precipitate was dissociated by the chaotrope for about 5 hours, and then the HA was alcohol-precipitated with 2 times the volume of 95% ethanol, dehydrated three times, and then vacuum-dried to obtain HA, and the yield was compared.

Embodiment 2

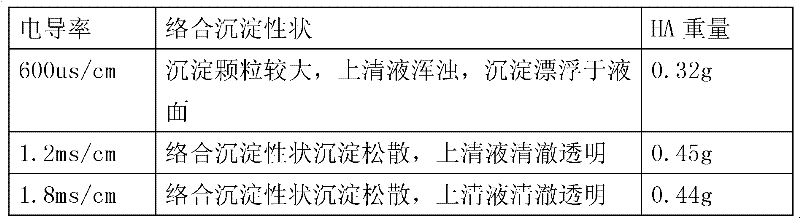

[0027] Sodium hyaluronate was prepared by the existing extraction method, and 2000ml of the filtrate was taken from the cockscomb enzymatic hydrolysis solution once activated carbon was adsorbed and filtered, and divided into 6 parts on average, numbered A, B, C, D, E, F respectively. Use purified water or sodium chloride to adjust the conductivity of the filtrate to the following: A-600us / cm, B-1.2ms / cm, C-1.8ms / cm, D-2.4ms / cm, E-3.0ms / cm, F-3.6ms / cm, respectively take 1.7g of CPC and add appropriate amount of water to dissolve, then complex and precipitate with the above 6 filtrates under the same conditions, collect the precipitate after complexation, and prepare 230ml of 0.4mol / L solution The complexed precipitate was dissociated by the chaotrope for about 5 hours, and then the HA was alcohol-precipitated with 2 times the volume of 95% ethanol, dehydrated three times, and then vacuum-dried to obtain HA, and the yield was compared.

Embodiment 3

[0029] Sodium hyaluronate was prepared by the existing extraction method, and 4800ml of the filtrate was taken from the cockscomb enzymatic hydrolysis solution once activated carbon adsorption and filtered, and divided into 6 parts on average, numbered A, B, C, D, E, F respectively. Use purified water or sodium chloride to adjust the conductivity of the filtrate to the following: A-600us / cm, B-1.2ms / cm, C-1.8ms / cm, D-2.4ms / cm, E-3.0ms / cm, F-3.6ms / cm, respectively take 3.2g of CPC and add appropriate amount of water to dissolve, then complex and precipitate with the above 6 filtrates under the same conditions, collect the precipitate after complexation, and prepare 520ml of 0.4mol / L solution The complexed precipitate was dissociated by the chaotrope for about 5 hours, and then the HA was alcohol-precipitated with 2 times the volume of 95% ethanol, dehydrated three times, and then vacuum-dried to obtain HA, and the yield was compared. Observe the properties of complexation and p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap