Polyethyleneimine (PEI) derivative taking amphipathic chitosan as cross linker and preparation method and application thereof

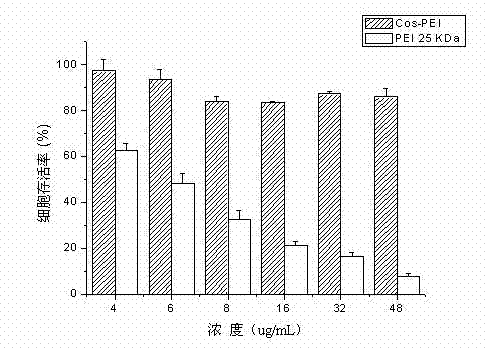

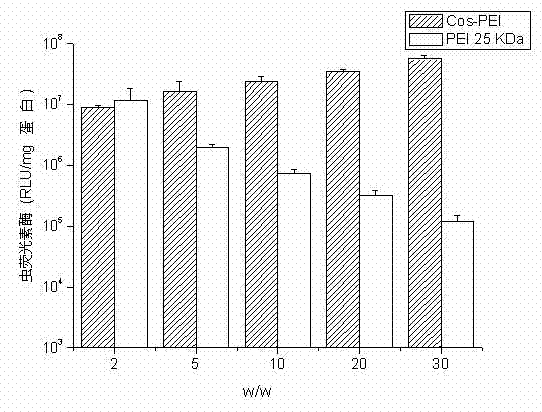

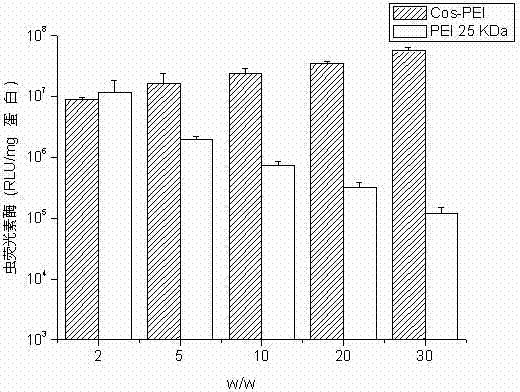

A technology of polyethylenimine and chitosan, applied in other methods of inserting foreign genetic materials, recombinant DNA technology, etc., to achieve the effects of increasing stability, reducing cytotoxicity, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of Polyethyleneimine Derivatives Using Amphiphilic Chitosan as a Crosslinking Agent

[0026] Add 6g of chitosan and 17.0ml of n-octanal into 125 mL of methanol, stir at 30°C for 12h, then add KBH in batches 4 3 g, stirred overnight, filtered, washed the filter cake repeatedly with water and hot methanol, and dried under vacuum at 50°C. Take 2 g of the above product, put it in a three-necked flask, add 30 mL of N-methylpyrrolidone, 5 g of KI, 10 mL of 15% NaOH aqueous solution and 10.4 mL of CH 3 1. Heat up to 60°C and react for 1 h under full stirring, cool to room temperature, centrifuge for 30 min (1000 r / min), collect the lower layer solid and dissolve it in distilled water, dialyze for 5 days, filter out the insoluble matter and freeze-dry the filtrate to obtain pale Yellow amphipathic chitosan.

[0027] Weigh 0.1 mmol of amphiphilic chitosan after water removal, add 1 mmol of triphosgene, dissolve in a mixed solution of anhydrous toluene ...

Embodiment 2

[0028] Example 2 Preparation of Polyethyleneimine Derivatives Using Amphiphilic Chitosan as Crosslinking Agent

[0029] Add 6g of chitosan and 17.0ml of n-decyl aldehyde into 125 mL of methanol, stir at 30°C for 12h, then add KBH in batches 43 g, stirred overnight, filtered, washed the filter cake repeatedly with water and hot methanol, and dried under vacuum at 50°C. Take 2 g of the above product, put it in a three-necked flask, add 30 mL of N-methylpyrrolidone, 5 g of KI, 10 mL of 15% NaOH aqueous solution and 10.4 mL of CH 3 1. Heat up to 60°C and react for 1 h under full stirring, cool to room temperature, centrifuge for 30 min (1000 r / min), collect the lower layer solid and dissolve it in distilled water, dialyze for 5 days, filter out the insoluble matter and freeze-dry the filtrate to obtain pale Yellow amphipathic chitosan.

[0030] Weigh 0.1 mmol of amphiphilic chitosan after water removal, add 0.1 mmol of triphosgene, dissolve in a mixed solution of anhydrous tol...

Embodiment 3

[0031] Example 3 Preparation of Polyethyleneimine Derivatives Using Amphiphilic Chitosan as Crosslinking Agent

[0032] Add 6g of chitosan and 17.0ml of lauric aldehyde into 125 mL of methanol, stir at 30°C for 12h, then add KBH in batches 4 3 g, stirred overnight, filtered, washed the filter cake repeatedly with water and hot methanol, and dried under vacuum at 50°C. Take 2 g of the above product, put it in a three-necked flask, add 30 mL of N-methylpyrrolidone, 5 g of KI, 10 mL of 15% NaOH aqueous solution and 10.4 mL of CH 3 1. Heat up to 60°C and react for 1 h under full stirring, cool to room temperature, centrifuge for 30 min (1000 r / min), collect the lower layer solid and dissolve it in distilled water, dialyze for 5 days, filter out the insoluble matter and freeze-dry the filtrate to obtain pale Yellow amphipathic chitosan.

[0033] Weigh 0.1 mmol of amphiphilic chitosan after water removal, add 0.5 mmol of triphosgene, dissolve in a mixed solution of anhydrous to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com