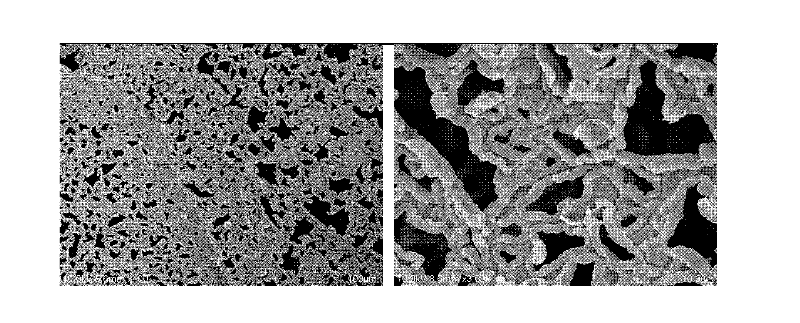

Method for preparing fibrillar meshwork structure conducting polypyrrole film by interfacial polymerization

A network structure, conductive polymerization technology, applied in the production of bulk chemicals, etc., can solve the problems of difficult to obtain high specific capacity and rate characteristics, and achieve the effects of excellent electrochemical performance, wide application prospects, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

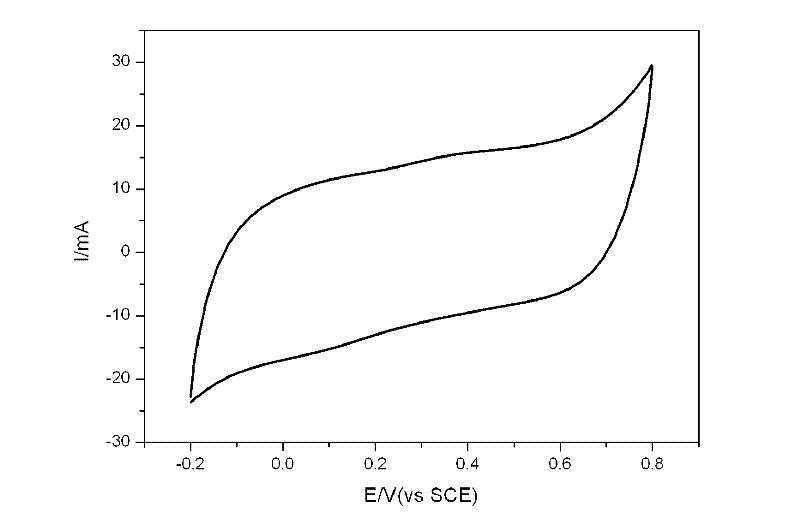

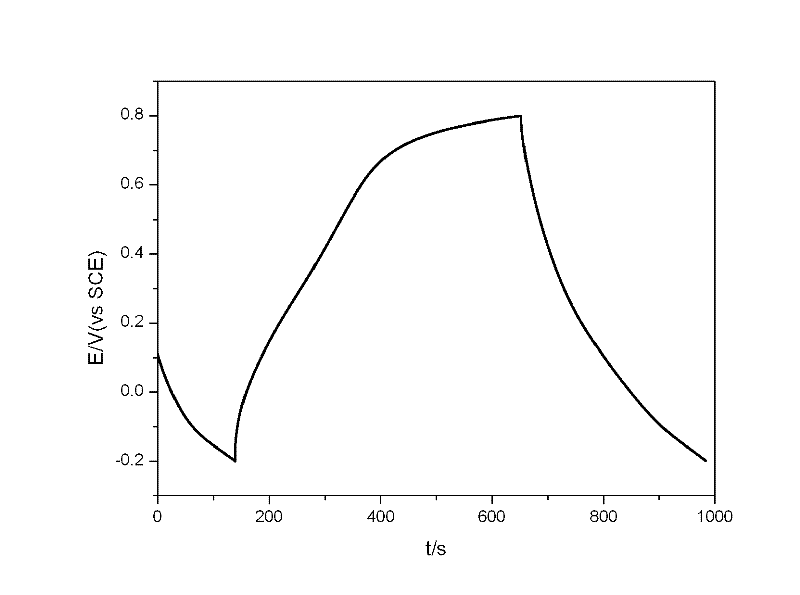

Image

Examples

Embodiment 1

[0022] A method for preparing a conductive polypyrrole film with a fiber network structure by interfacial polymerization, comprising the following steps:

[0023] (1) Dissolve 70 μL of pyrrole in 20 mL of n-hexane (concentration of solution is 0.05M), sonicate and set aside;

[0024] (2) Take 0.26g of 1-butyl-3-methylimidazole ferric tetrachloride (purchased from Shanghai Chengjie Chemical Co., Ltd.) and add it to 20mL of 1M HCl to obtain 1-butyl-3-methylimidazole with a concentration of 0.038M Imidazolium tetrachloride solution, ultrasound, standby; pyrrole: 1-butyl-3 methylimidazolium tetrachloride=1.3: 1 (molar ratio);

[0025] (3) Slowly inject the pyrrole solution obtained in step (1) along the container wall of step (2) with a dropper (dropping rate: 2-5mL / min), layering, and carrying out interfacial reaction, the upper layer of the interface is transparent and colorless liquid It is the n-hexane solution of pyrrole monomer, and the transparent bright yellow liquid in t...

Embodiment 2

[0027] A method for preparing a conductive polypyrrole film with a fiber network structure by interfacial polymerization, comprising the following steps:

[0028] (1) Dissolve 105 μL of pyrrole in 20 mL of 1-butyl-3-methylimidazolium hexafluorophosphate (purchased from Shanghai Chengjie Chemical Co., Ltd.) (solution concentration: 0.075 M), ultrasonicate, and set aside;

[0029] (2) Take 0.17g 1-butyl-3 methylimidazolium tetrachloride (purchased from Shanghai Chengjie Chemical Co., Ltd.) and add 20mL 1M HClO 4 In, obtain the 1-butyl-3 methylimidazole ferric tetrachloride solution that concentration is 0.025M, ultrasonic, standby; Pyrrole: 1-butyl-3 methylimidazole ferric tetrachloride=3: 1 (molar ratio) ;

[0030] (3) The 1-butyl-3 methylimidazole ferric tetrachloride solution obtained in step (2) is slowly injected (dropping speed: 2-5mL / min) along the container wall of step (1) with a dropper, divided into Layer, carry out interfacial reaction, the transparent bright yello...

Embodiment 3

[0032] The method for preparing a conductive polypyrrole membrane with a fiber network structure by interfacial polymerization is different from Example 2 in that 105 μL pyrrole is changed to 35 μL (solution concentration is 0.025M), 1M HCl is changed to 0.05M sodium p-aminobenzenesulfonate aqueous solution, 0.17 g 1-butyl-3 methylimidazole ferric tetrachloride becomes 0.08g 1-butyl-3 methylimidazolium tetrachloride, pyrrole: 1-butyl-3 methylimidazolium tetrachloride=2: 1 (molar ratio), 1-butyl-3-methylimidazolium hexafluorophosphate becomes 1-octyl-3-methylimidazolium hexafluorophosphate, and the standing reaction time becomes 12h. The thickness of the polypyrrole film was 0.12 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com