Warm white mixed fluorescent material with color rendering index of more than 90 and preparation method thereof

A fluorescent material, warm white light technology, applied in luminescent materials, chemical instruments and methods, climate sustainability, etc., can solve problems such as energy consumption, and achieve the effects of stable product quality, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

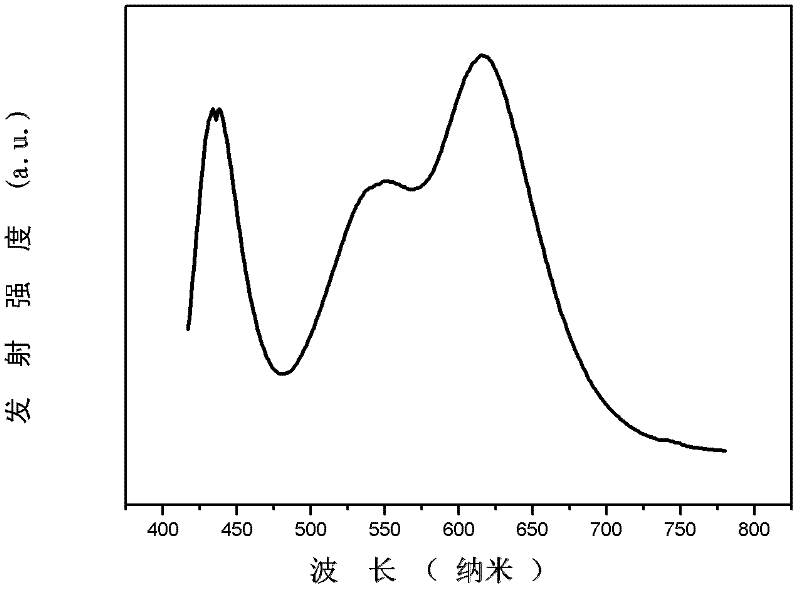

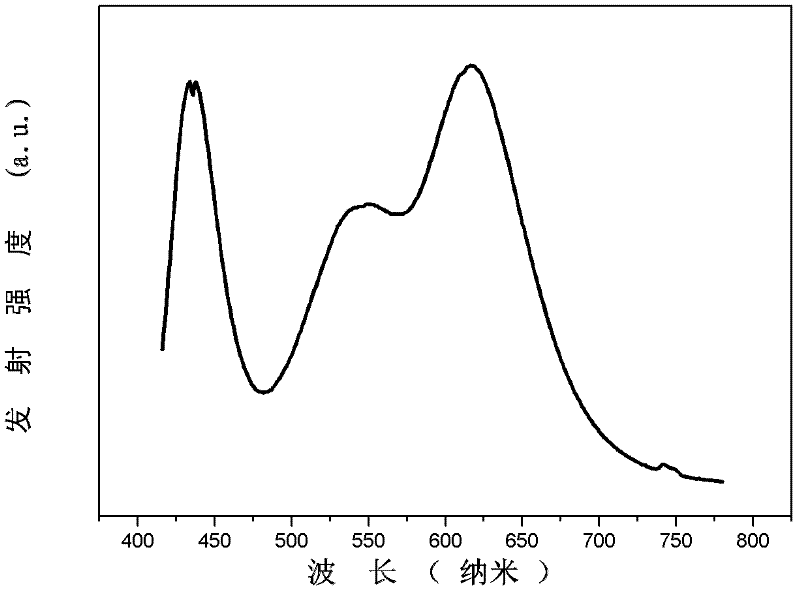

Image

Examples

Embodiment 1

[0024] A kind of warm white light mixed fluorescent material with color rendering greater than 90, made of Ba 2.84 MgSi 2 o 8 :0.06Eu 2+ , 0.1Mn 2+ and Sr 1.94 SiO 4 :0.06Eu 2+ Composition, Ba 2.84 MgSi 2 o 8 :0.06Eu 2+ , 0.1Mn 2+ with Sr 1.94 SiO 4 :0.06Eu 2+ The molar ratio is 1:0.35.

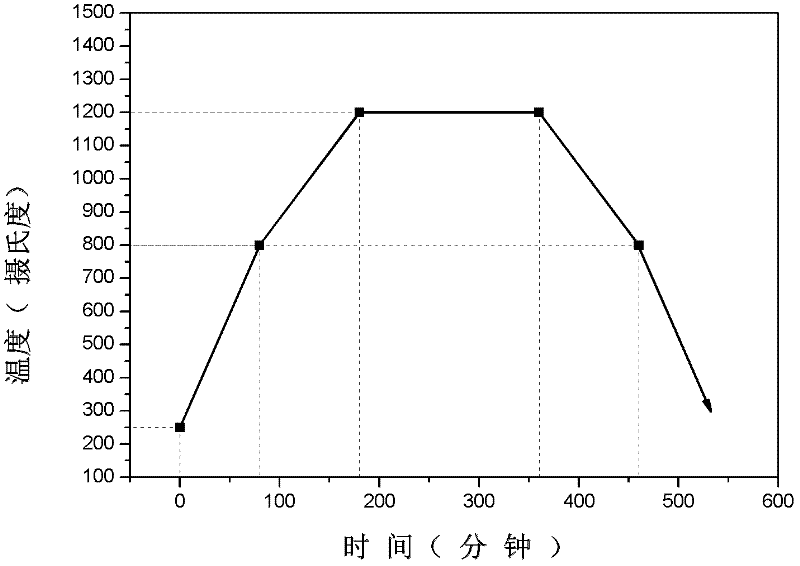

[0025] The preparation method of the mixed fluorescent material is prepared by a high-temperature microwave method, and the steps are as follows:

[0026] 1) Press Ba 2.84 MgSi 2 o 8 :0.06Eu 2+ , 0.1Mn 2+ The molar ratio of each component is 142:50:100:3:5:30 and weighs 5.6611 grams of BaCO 3 , 0.4034 grams of MgO, 1.2016 grams of SiO 2 , 0.1056 g Eu 2 o 3 , 0.1151 g MnCO 3 , 0.3213 g NH 4 Cl, according to the volume ratio of raw materials and absolute ethanol is 1:1, add absolute ethanol and stir until slurry and disperse evenly, then dry at 60°C for 10 hours, grind and loosen, place in a crucible and put in a high-temperature microwave oven , feed the mixed gas of ...

Embodiment 2

[0031] A kind of warm white light mixed fluorescent material with color rendering greater than 90, made of Ba 2.83 MgSi 2 o 8 :0.07Eu 2+ , 0.1Mn 2+ with Sr 1.93 SiO 4 :0.07Eu 2+ Composition, Ba 2.83 MgSi 2 o 8 :0.07Eu 2+ , 0.1Mn 2+ with Sr 1.93 SiO 4 :0.07Eu 2+ The molar ratio is 1:0.425.

[0032] The preparation method of the mixed fluorescent material is prepared by a high-temperature microwave method, and the steps are as follows:

[0033] 1) Press Ba 2.83 MgSi 2 o 8 :0.07Eu 2+ , 0.1Mn 2+ The molar ratio of each component is 283:100:200:7:10:60 and weighs 5.6411 grams of BaCO 3 , 0.4034 grams of MgO, 1.2016 grams of SiO 2 , 0.1232 grams of Eu 2 o 3 , 0.1151 g MnCO 3 , 0.3213 g NH 4 Cl, according to the volume ratio of raw materials and absolute ethanol as 1:1, add ethanol and stir until slurry and disperse evenly, then dry at 60°C for 10 h, grind and loosen, place in a crucible and put it in a high-temperature microwave oven, Enter the mixture of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com