Alkaline earth nitride fluorescent powder and preparation method thereof

A nitride phosphor, alkaline earth technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of high synthesis conditions and high cost of nitride phosphors, and achieve excellent luminescence performance, long service life, physical and chemical properties. Stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

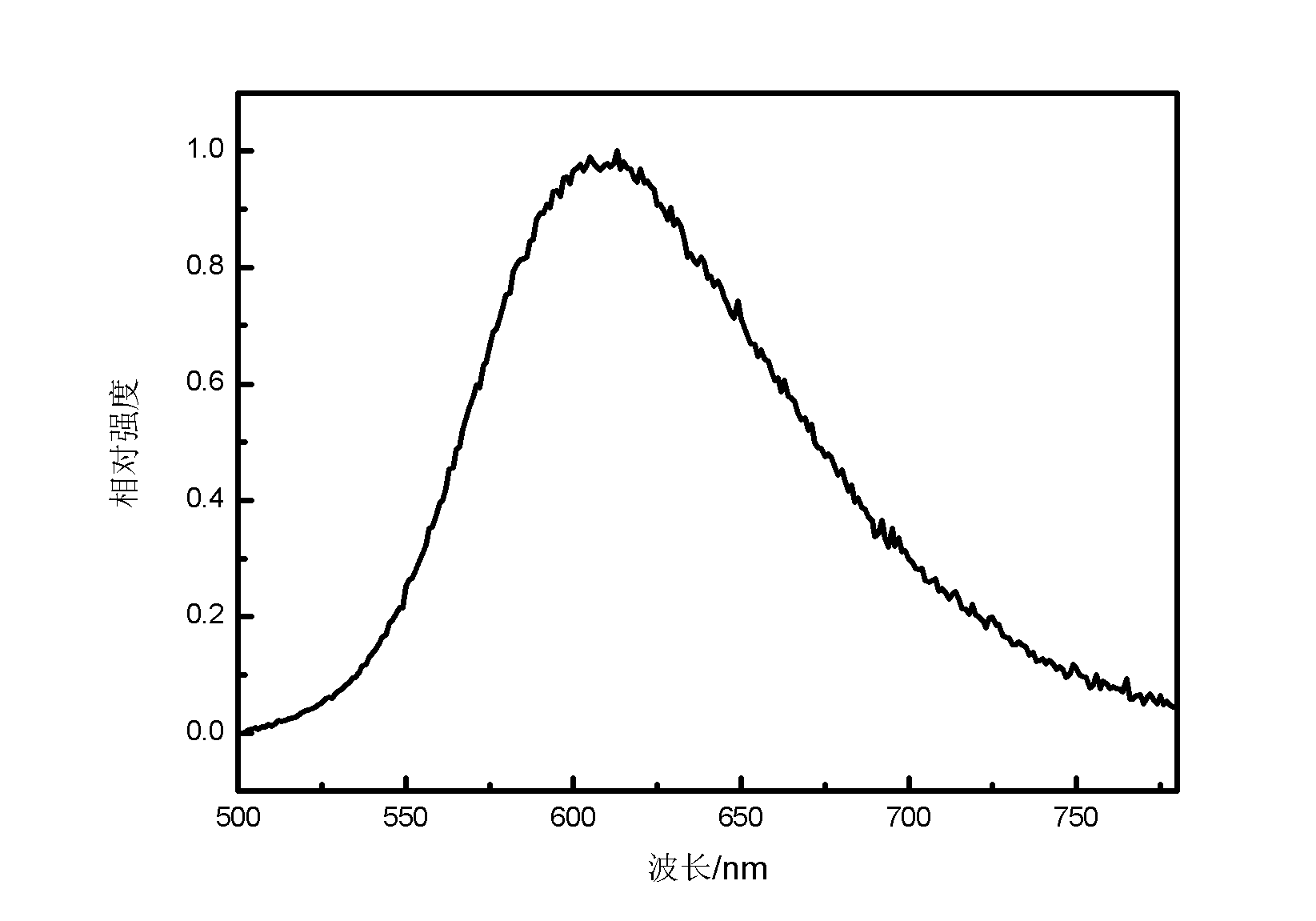

[0023] Select the batching point m=0.02, the CaSi alloy with a purity of not less than 99.5% (molar ratio is 1:1), α-Si 3 N 4 Powder, Eu 2 o 3 Put it in a mortar with a molar ratio of 196:101:2, use n-hexane as the dispersion medium, fully grind until uniform, dry, and press into tablets. Then loaded in the graphite furnace, under 5 atmospheres of N 2 Under the protection of the atmosphere, the temperature was raised to 1400°C for sintering for 4 hours and then cooled with the furnace. The final specific expression of the obtained nitride is 0.653Ca 3 N 2 1.667Si 3 N 4 :0.04Eu 2+ . The position of the main emission peak of the prepared nitride material is at 609nm.

Embodiment 2

[0025] Select the batching point m=0.02, the CaSi alloy with a purity of not less than 99.5% (molar ratio is 1:1), α-Si 3 N 4 Powder, EuSi molar ratio 49:25:1, placed in a mortar, using n-hexane as the dispersion medium, fully ground until uniform, and dried. Then loaded in the graphite furnace, under 5 atmospheres of N 2Under the protection of the atmosphere, the powder is sintered, and the temperature is raised to 1400°C for 4 hours and then cooled with the furnace. The final specific expression of the obtained nitride is 0.653Ca 3 N 2 1.667Si 3 N 4 :0.04Eu 2+ . The position of the main emission peak of the prepared nitride material is at 610nm.

Embodiment 3

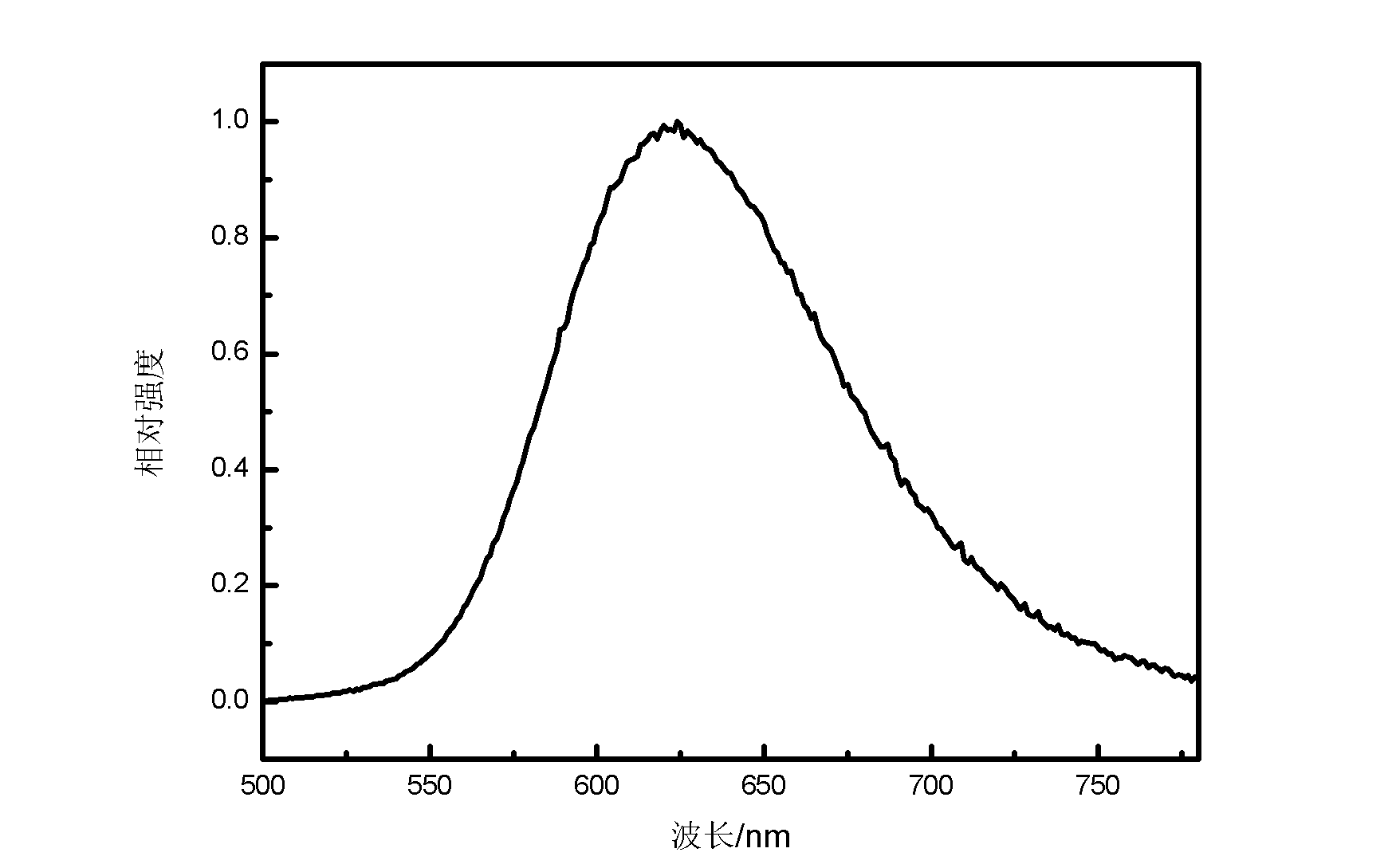

[0027] Select the dosing point m=0.02, the SrSi alloy with a purity of not less than 99.5% (molar ratio is 1:1), α-Si 3 N 4 The powder, EuSi, is placed in a mortar with a molar ratio of 49:25:1, with n-hexane as the dispersion medium, fully ground until uniform, dried, and pressed into tablets. Then loaded in the graphite furnace, under 5 atmospheres of N 2 Under the protection of the atmosphere, the temperature was raised to 1400°C for sintering for 4 hours and then cooled with the furnace. The final specific expression of the obtained nitride is 0.653Sr 3 N 2 1.667Si 3 N 4 :0.04Eu 2+ . The position of the main emission peak of the prepared nitride material is at 621nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com