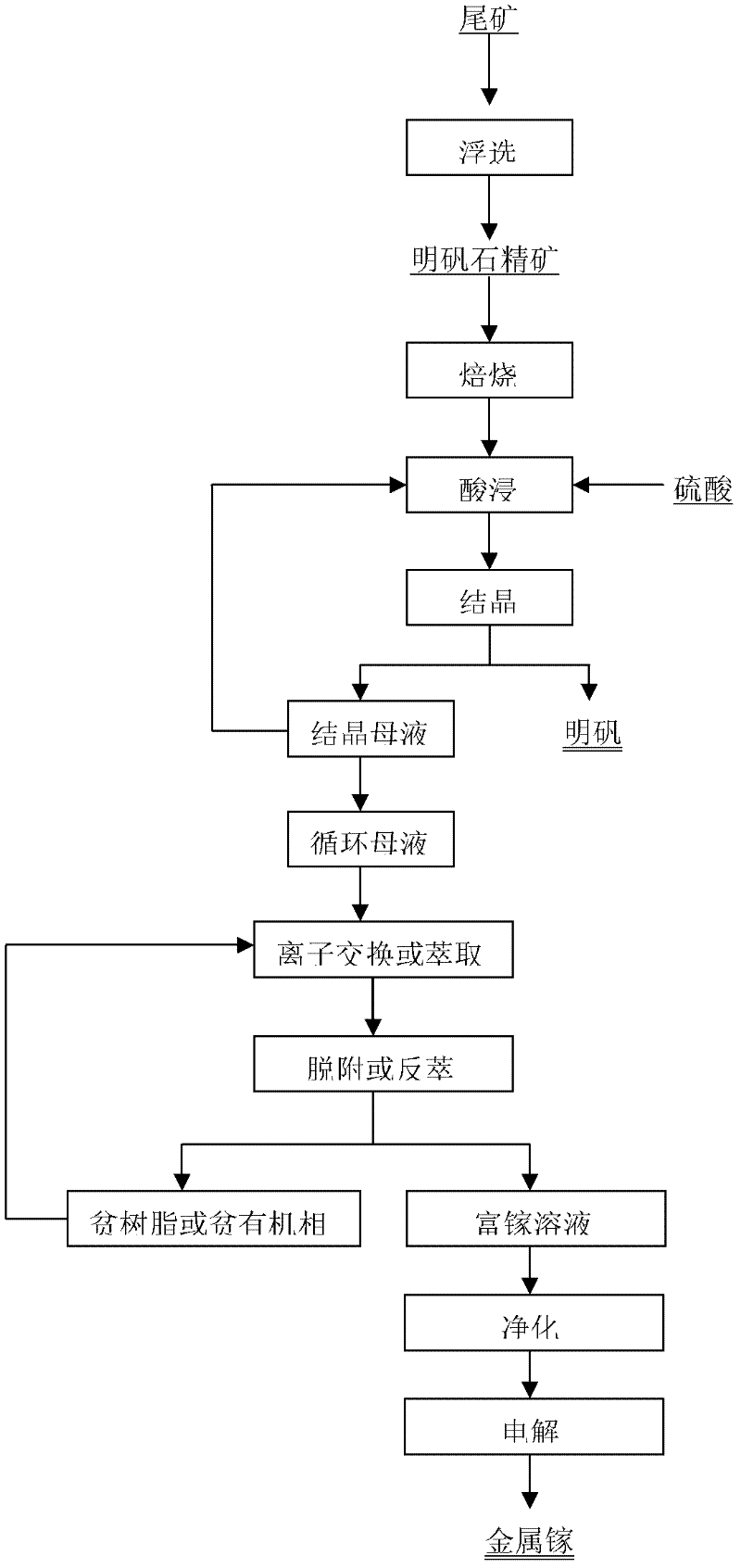

Method for recycling gallium in alunite concentrate

A technology of alunite and concentrate, applied in the field of gallium recovery, can solve the problems of harsh method conditions, long process flow, and little practical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

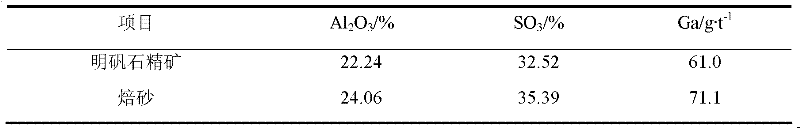

[0025] Example 1: Put the alunite concentrate in a muffle furnace for roasting at a temperature of 400°C and a time of 0.5 hours; leaching the obtained calcined sand with sulfuric acid under the conditions of L / S=4 and a temperature of 90°C , time 0.5 hours, acidity 50g / L, natural crystallization after acid leaching to obtain alunite product and mother liquor after crystallization, take out crystallized alum, add crystallization mother liquor to acidity 50g / L and return to calcined acid leaching, and cycle like this for 6 The crystallization mother liquor obtained after the second time contains gallium 100mg / L, adopts CL-TBP resin to adsorb gallium, adopts 0.15mol / L NH4Cl solution to carry out elution after adsorption saturation, and eluting barren solution returns calcination acid leaching to carry out circulation, and resin returns again Adsorption, the comprehensive recoveries of gallium and alum in this process are 95.3% and 95.8% respectively, and the alum yield is 1.95t a...

example 2

[0026] Example 2: The alunite concentrate is first placed in a fluidized bed furnace for roasting, the roasting conditions are temperature 500°C, time 1 hour; the obtained calcined sand is leached with sulfuric acid, the acid leaching conditions are L / S=5, temperature 90°C, time 1.0 hours, acidity 100g / L, natural crystallization after acid leaching to obtain alunite product and mother liquor after crystallization, take out the crystallized alum, add mother liquor after crystallization to acidity 100g / L and return to calcination acid leaching, cycle like this 10 times The obtained crystallization mother liquor contains gallium 160mg / L, adopts AR-16 resin to absorb gallium, uses 150g / L sulfuric acid solution to carry out elution after adsorption saturation, elutes barren solution and returns calcination acid leaching to circulate, and resin returns to re-absorb, The comprehensive recoveries of gallium and alum are 96.3% and 96.8% respectively, and the yield of alum is 2.0t alum / t...

example 3

[0027] Example 3: The alunite concentrate is first placed in an industrial microwave oven for roasting, the roasting conditions are a temperature of 600°C and a time of 0.5 hours; the obtained calcined sand is leached with sulfuric acid, and the acid leaching conditions are L / S=6, a temperature of 90°C, Time 1.0 hours, acidity 170g / L, natural crystallization after acid leaching to obtain alunite product and mother liquor after crystallization, take out the crystallized alum, add mother liquor after crystallization to acidity 170g / L, then return to calcination and acid leaching, and cycle like this for 15 The obtained crystallization mother liquor contains 250mg / L of gallium, adopts p507 resin to adsorb gallium, and uses 1.0mol / L NH4Cl solution to elute after the adsorption is saturated, and returns the eluted barren solution to calcination acid leaching for circulation, and the resin returns to re-adsorb. The comprehensive recoveries of gallium and alum in this process are 96.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com