Pollution flashover-prevention, corrosion-prevention and freezing-prevention electric tower and surface treatment method thereof

A power tower and anti-icing technology, which is applied to the anti-icing power tower and its surface treatment, anti-corrosion and anti-fouling fields, can solve the problems of steel towers and steel rods breaking and collapsing, increasing the tensile force of iron towers, and icing on the surface of transmission wires. , to achieve the effect of reducing costs, saving manpower and material resources, and saving man-hours in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

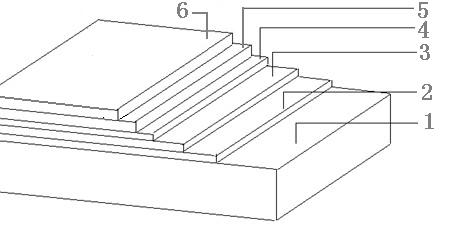

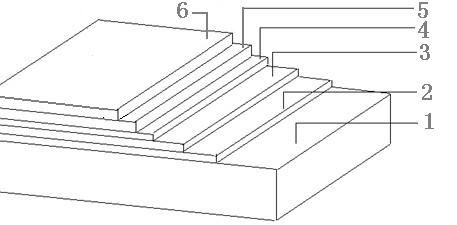

[0017] Accompanying drawing is a kind of specific embodiment of the present invention.

[0018] The anti-fouling, anti-corrosion and anti-icing power tower of the present invention comprises several steel rods installed together by bolts and flanges, the steel rod substrate 1 is sequentially provided with an inner treatment layer 2 of shot blasting treatment from inside to outside, spraying The epoxy zinc-rich primer layer 3, the epoxy sealing paint layer 4, the epoxy mica iron intermediate paint layer 5 and the fluorocarbon topcoat layer 6.

[0019] The anti-fouling, anti-corrosion and anti-icing surface treatment method of the power tower of the present invention consists of the following steps:

[0020] (1) Material selection: select high-quality steel materials above Q345 and Q420;

[0021] (2) Sandblasting and derusting: sandblasting the surface of the steel to obtain a certain degree of cleanliness and roughness (Sa2.5 grade);

[0022] (3) Spray epoxy zinc-rich primer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com