Duralumin/silicon carbide extreme ultraviolet multilayer reflector and manufacturing method for the same

A silicon carbide and multi-layer film technology, applied in chemical instruments and methods, glass/slag layered products, coatings, etc., can solve the problems of high cost and large interface roughness of Al-based multi-layer films, and reduce production cost, reduce the difficulty of the production process, and improve the effect of the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] First, clean the base optical glass, including the following steps: ultrasonic cleaning with ultrapure water for 10 minutes, organic cleaning liquid white cat detergent ultrasonic cleaning for 10 minutes, ultrapure water ultrasonic cleaning for 5 minutes, and MOS grade acetone ultrasonic cleaning for 10 minutes , ultrapure water ultrasonic cleaning for 10 minutes, ultrasonic cleaning of MOS grade ethanol and ether mixture for 10 minutes, the volume ratio of ethanol and ether is 1:1, and dry with pure nitrogen gas. The base roughness is: 0 nanometer<base roughness<1 nanometer.

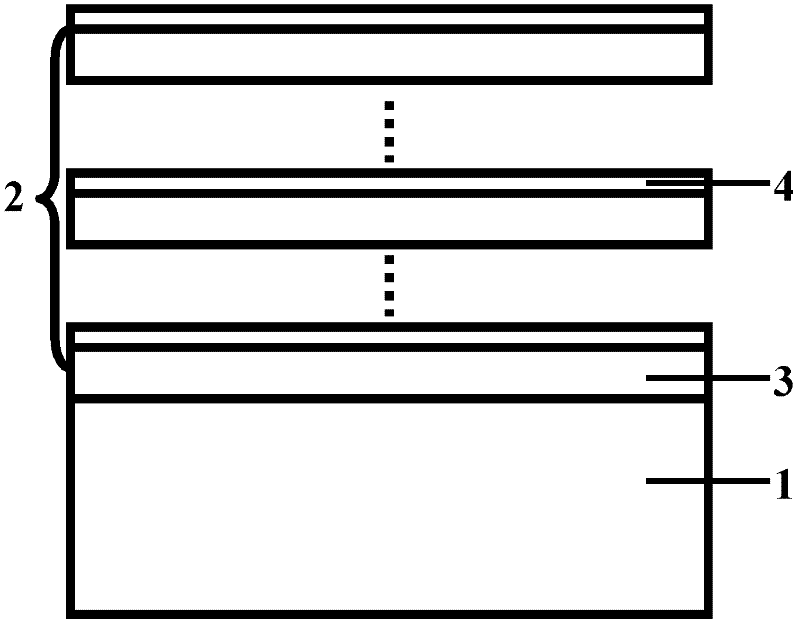

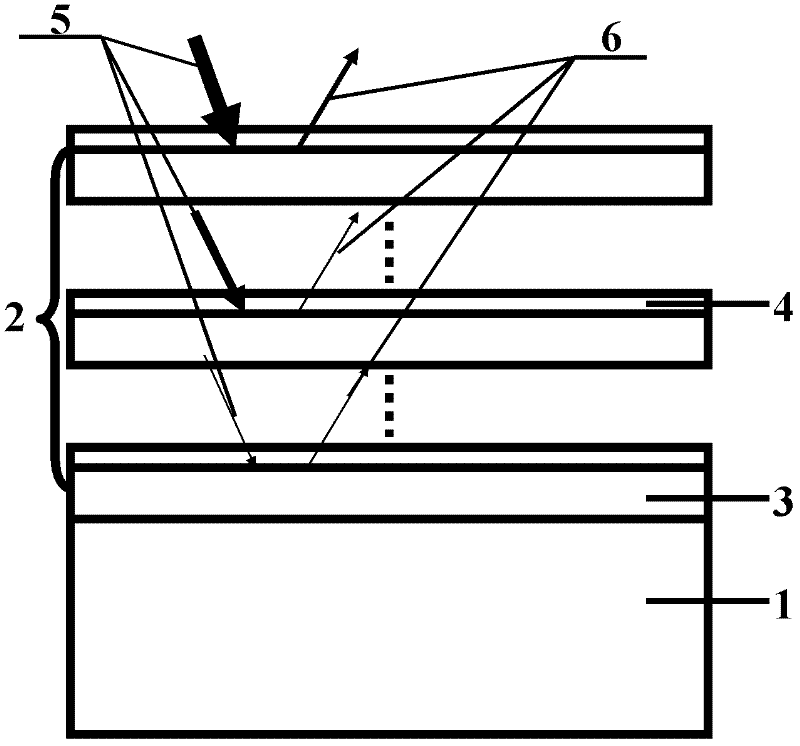

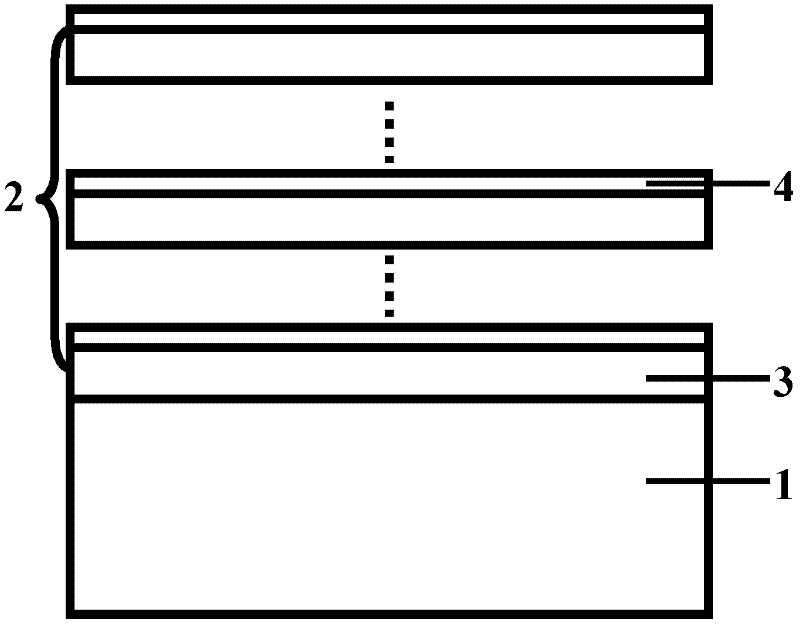

[0034] Then plate a duralumin / silicon carbide periodic multilayer film on the substrate optical glass, using the magnetron sputtering method, including the following steps: the working mode of the sputtering target gun is constant power sputtering, and the sputtering working pressure is 1 millitorr ;Before coating the multi-layer film, the background vacuum of the sputtering chamber is 5E-5 Pasca...

Embodiment 2

[0038] First, clean the base optical glass, including the following steps: ultrasonic cleaning with ultrapure water for 10 minutes, organic cleaning liquid white cat detergent ultrasonic cleaning for 10 minutes, ultrapure water ultrasonic cleaning for 5 minutes, and MOS grade acetone ultrasonic cleaning for 10 minutes , ultrapure water ultrasonic cleaning for 10 minutes, ultrasonic cleaning of MOS grade ethanol and ether mixture for 10 minutes, the volume ratio of ethanol and ether is 1:1, and dry with pure nitrogen gas. The base roughness is: 0 nanometer<base roughness<1 nanometer.

[0039] Then plate a duralumin / silicon carbide periodic multilayer film on the substrate optical glass, using the magnetron sputtering method, including the following steps: the working mode of the sputtering target gun is constant power sputtering, and the sputtering working pressure is 1 millitorr ;Before coating the multi-layer film, the background vacuum of the sputtering chamber is 5E-5 Pasca...

Embodiment 3

[0042] First, clean the base optical glass, including the following steps: ultrasonic cleaning with ultrapure water for 10 minutes, organic cleaning liquid white cat detergent ultrasonic cleaning for 10 minutes, ultrapure water ultrasonic cleaning for 5 minutes, and MOS grade acetone ultrasonic cleaning for 10 minutes , ultrapure water ultrasonic cleaning for 10 minutes, ultrasonic cleaning of MOS grade ethanol and ether mixture for 10 minutes, the volume ratio of ethanol and ether is 1:1, and dry with pure nitrogen gas. The base roughness is: 0 nanometer<base roughness<1 nanometer.

[0043] Then plate a duralumin / silicon carbide periodic multilayer film on the substrate optical glass, using the magnetron sputtering method, including the following steps: the working mode of the sputtering target gun is constant power sputtering, and the sputtering working pressure is 1 millitorr ;Before coating the multi-layer film, the background vacuum of the sputtering chamber is 5E-5 Pasca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com