Method and system for manufacturing hologram and holographic lens combined element

A holographic lens and composite element technology, applied in optical elements, optics, instruments, etc., can solve the problems of complex optical path system and lack of diffraction holographic image properties, and achieve the effect of simple manufacturing method, easy implementation, and overcoming functional defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

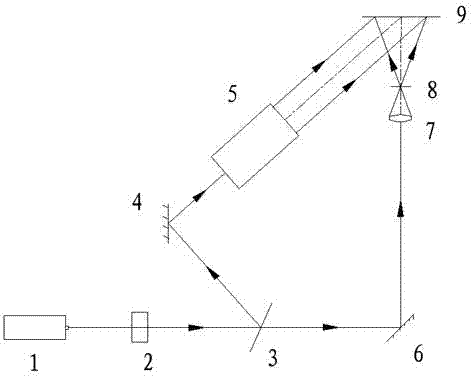

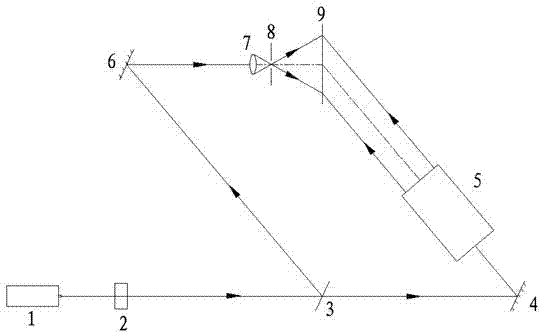

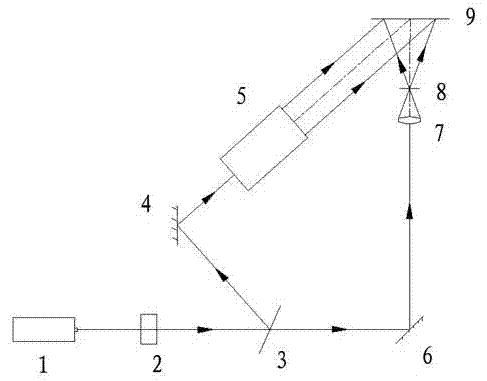

[0028] The technical core of the present invention is that a combination of a hologram and a holographic lens is produced by interference of a beam of parallel object light and a beam of divergent light. The component simultaneously records the properties of the lens and the image of the object. The holographic lens combination can be The transmissive holographic composite element may also be a reflective holographic composite element.

[0029] figure 1 Shown is a schematic diagram of the optical path for producing a transmission hologram and a holographic composite element. The specific production process is: a laser light source 1 emits a beam of laser light, which is divided into two beams of light after passing through the diaphragm 2 and the beam splitter 3 (that is, a beam of reflected light and a beam of transmitted light) are respectively reflected by the first reflector 4 and the second reflector 6, and the transmitted light reflected by the second reflector 6 becomes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com