Pig feed and production method thereof

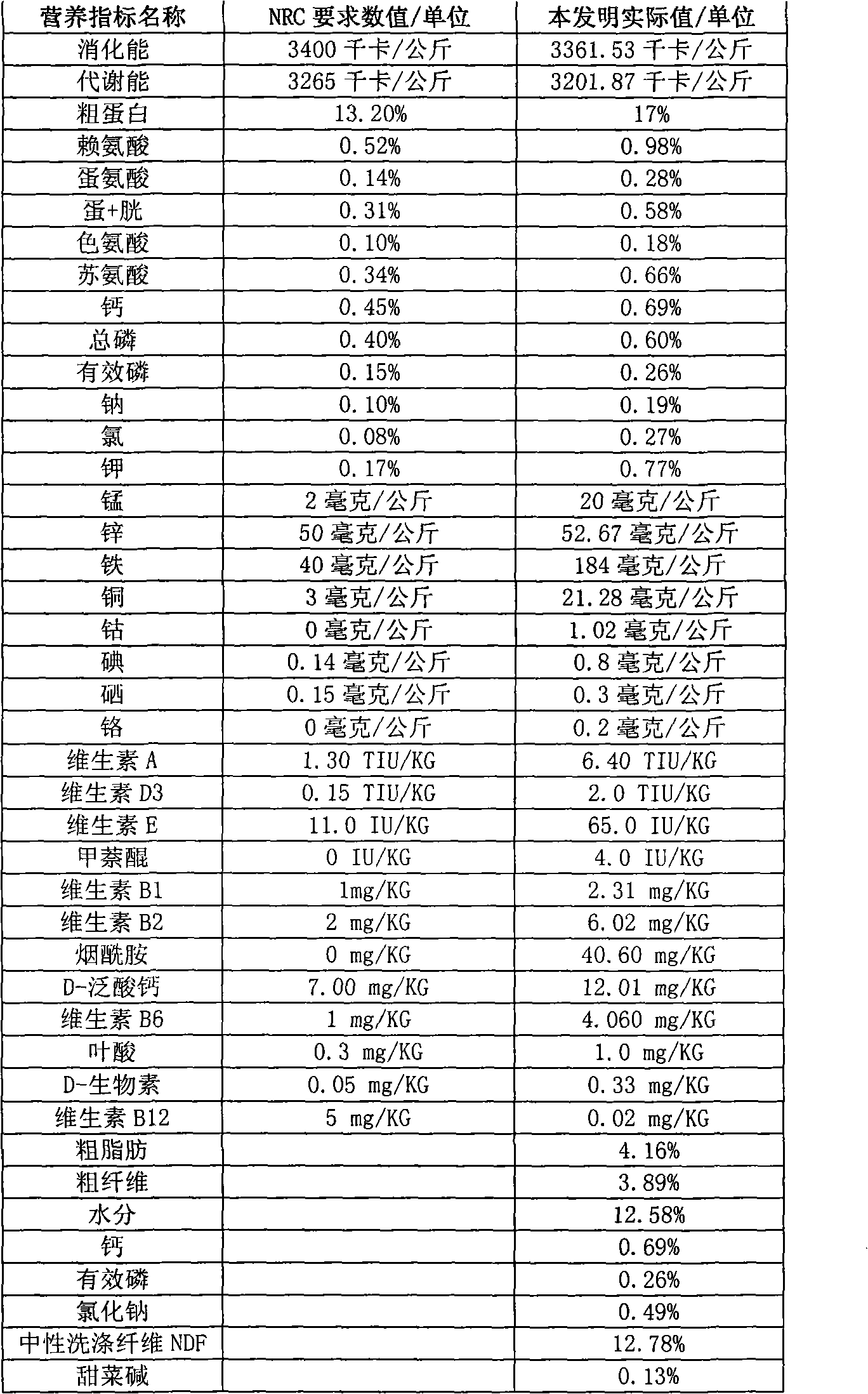

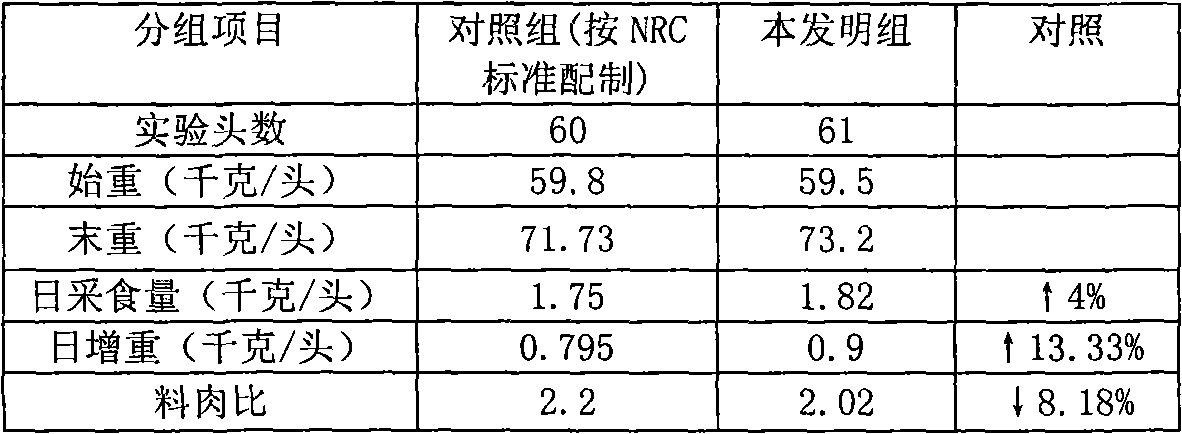

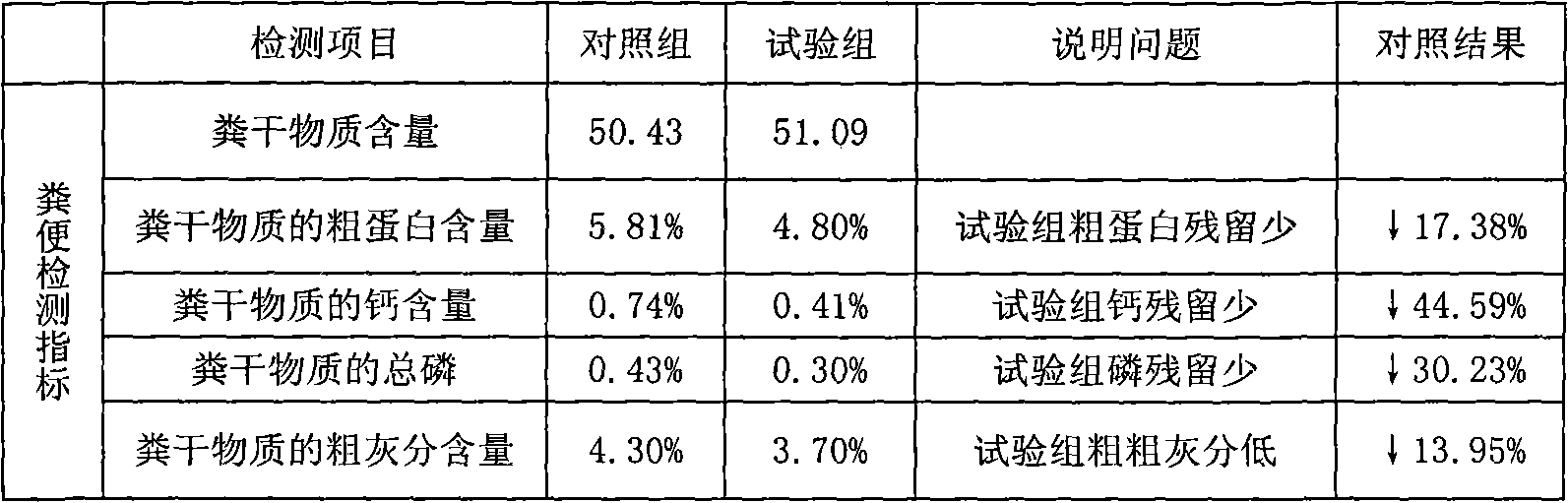

A production method and technology for pig feed, applied in the direction of animal feed, animal feed, application, etc., can solve the problem of excessive production, and achieve the effects of improving production performance, promoting feed intake, and reducing backfat thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A pig feed and production method thereof, comprising the following components, each component by weight: 62% corn flour, 8% wheat bran, 24% soybean meal, 1.8% fat powder, 4.2% premix, characterized in that The calculated premix 4.2% is composed of the following components, each component is still by weight: zeolite powder 3.5%, choline 0.18%, copper sulfate pentahydrate 0.1%, ferrous sulfate monohydrate 0.09%, zinc sulfate monohydrate 0.04%, manganese sulfate monoacid 0.04%, cobalt chloride 0.03%, sodium selenite 0.015%, potassium iodide 0.06%, pig multidimensional 0.07%, betaine 0.02%, phytase 0.02%, Gannan medical stone 0.02 % composed of;

[0014] According to a kind of pig feed production method described above, it is characterized in that the production steps are as follows:

[0015] Step 1: Grind 62% of corn flour, 8% of wheat bran, 24% of soybean meal, and 1.8% of fat powder by weight into 6-12 mesh particles, and lift them to the powder silo, and use the comput...

Embodiment 2

[0020] 1. A pig feed and production method thereof, comprising the following components, each component by weight: 62.5% corn flour, 8.5% wheat bran, 23.5% soybean meal, 1.5% fat powder, 4% premix, characterized in that The premix 4% by weight is composed of the following components, each component is still by weight: zeolite powder 3.8%, choline 1.5%, copper sulfate pentahydrate 0.12%, ferrous sulfate monohydrate 0.095%, monohydrate Zinc sulfate 0.05%, monoacid manganese sulfate 0.045%, cobalt chloride 0.04%, sodium selenite 0.015.5%, potassium iodide 0.06.5%, pig multidimensional 0.075%, betaine 0.025%, phytase 0.025%, Gannan medical stone composed of 0.03%;

[0021] 2. A pig feed production method according to claim 1, characterized in that the production steps are as follows:

[0022] Step 1: Grind 62.5% of corn flour, 8.5% of wheat bran, 23.5% of soybean meal, and 1.5% of fat powder by weight into 6-12 mesh particles, and lift them to the powder silo, and use the compute...

Embodiment 3

[0027] 1. A pig feed and production method thereof, comprising the following components, each component by weight: 63% corn flour, 9% wheat bran, 23% soybean meal, 1.2% fat powder, 3.8% premix, characterized in that The premix 3.8% by weight is composed of the following components, each component is still by weight: zeolite powder 4%, choline 2.2%, copper sulfate pentahydrate 0.13%, ferrous sulfate monohydrate 0.1%, monohydrate Zinc sulfate 0.06%, manganese sulfate monoacid 0.05%, cobalt chloride 0.05%, sodium selenite 0.016%, potassium iodide 0.07%, pig multidimensional 0.08%, betaine 0.03%, phytase 0.03%, Gannan wheat rice Composed of 0.05% stone;

[0028] 2. A pig feed production method according to claim 1, characterized in that the production steps are as follows:

[0029] Step 1: Grind 63% of corn flour, 9% of wheat bran, 23% of soybean meal, and 1.2% of fat powder by weight into 6-12 mesh particles, and lift them to the powder silo, and use the computer to precisely co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com