Method for boosting crystallization of phase-change cold-storing material of eutectic salt solution

A cold storage material and phase change cold storage technology, applied in the direction of solution crystallization, heat exchange materials, chemical instruments and methods, etc., can solve the problems of affecting cold storage efficiency, reducing the working efficiency of refrigeration units, energy waste, etc., and achieve the elimination of nucleation The effect of supercooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

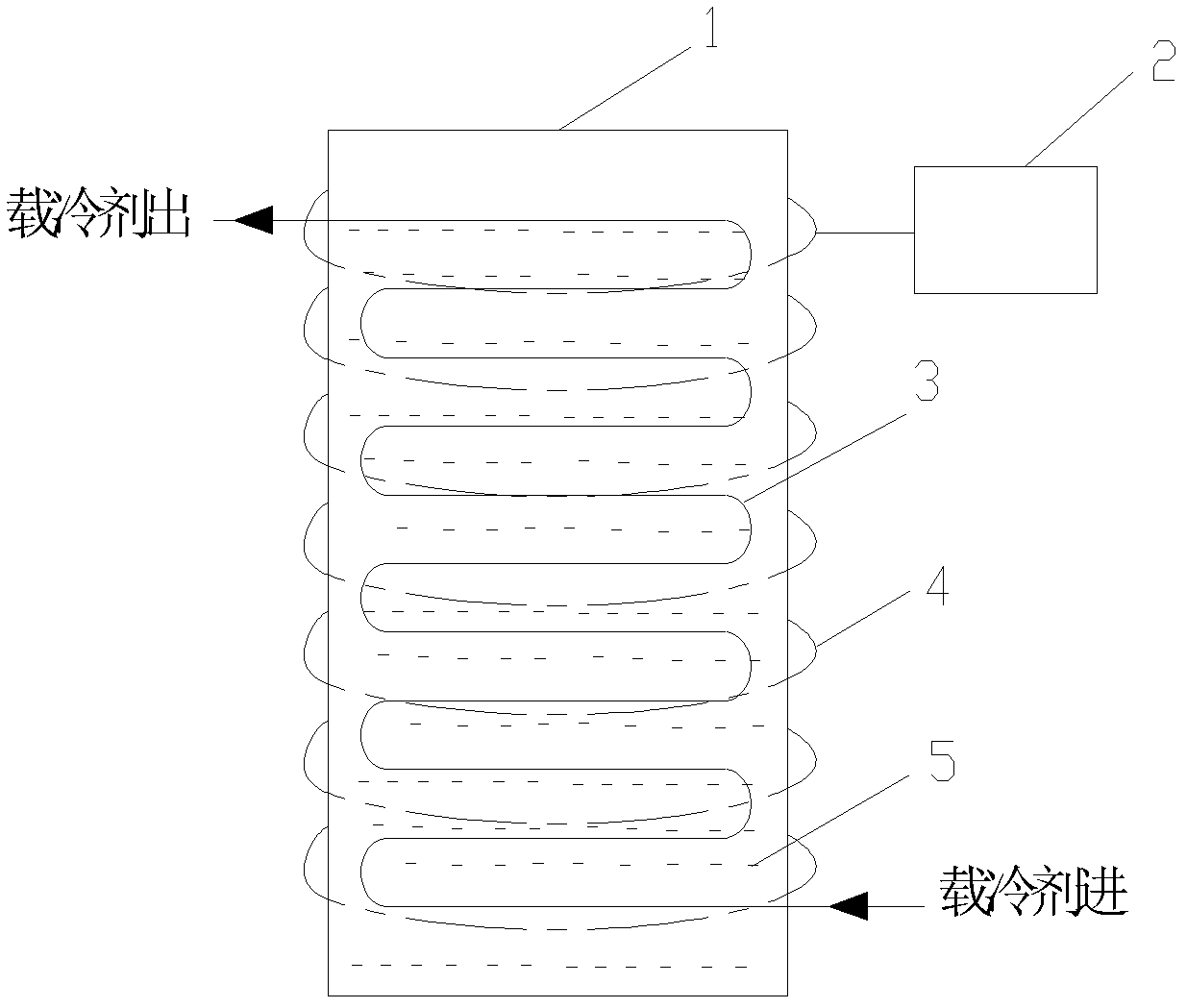

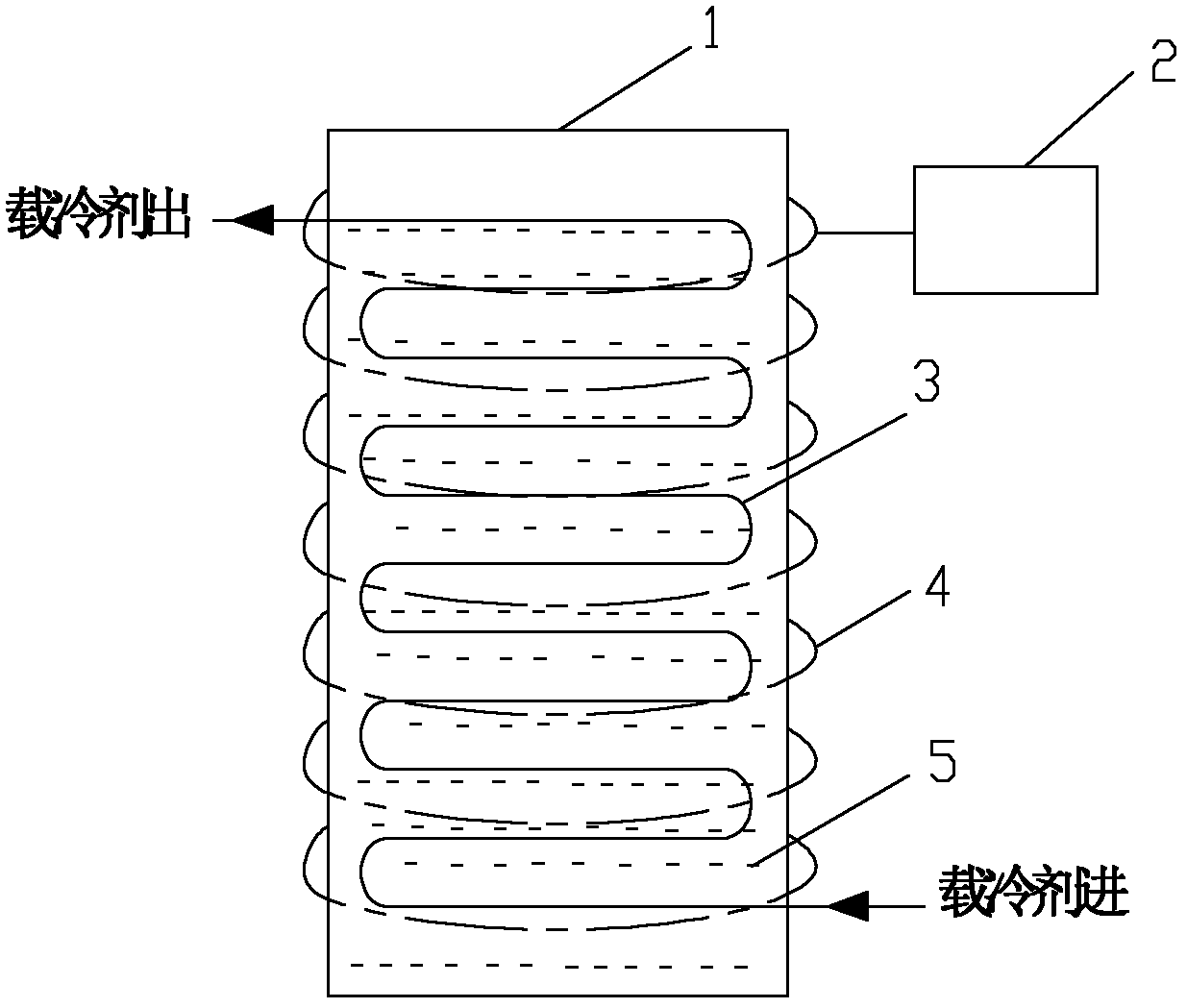

Image

Examples

Embodiment 1

[0021] Nano Fe 3 o 4 Particle plus magnetic field promotes BaCl 2 Aqueous solution crystallization, the volume fraction is 1.2% Fe 3 o 4 Nanoparticles and 100 parts of BaCl with a mass concentration of 26.4% 2 Aqueous solution mixing, in order to make Fe 3 o 4 Nanoparticles are uniformly suspended in BaCl 2 In the aqueous solution, a composite dispersant of sodium tripolyphosphate and triethanolamine is selected, the volume fraction of the dispersant is 0.6%, and then ultrasonic vibration is carried out for 30 minutes to obtain a suspended and stable Fe 3 o 4 -BaCl 2 -H 2 O cold storage material, the magnetic field strength during crystallization is 550Gauss, its nucleation supercooling degree is reduced by 94.2%, and the crystallization time is shortened by 75.2%.

Embodiment 2

[0023] Nano Fe 3 o 4 Adding a magnetic field to the particles promotes the crystallization of KCl aqueous solution, and the volume fraction of 0.1% Fe 3 o 4 The nanoparticles were mixed with 100 parts of KCl aqueous solution with a mass concentration of 25.5%, in order to make Fe 3 o 4 Nanoparticles are uniformly suspended in KCl aqueous solution, a composite dispersant of sodium tripolyphosphate and triethanolamine is selected, the volume fraction of the dispersant is 0.36%, and then ultrasonic vibration is carried out for 40 minutes to obtain a suspended and stable Fe 3 o 4 -KCl-H 2 O cold storage material, the magnetic field strength during crystallization is 600Gauss, its nucleation supercooling degree is reduced by 35.4%, and the crystallization time is shortened by 28.5%.

Embodiment 3

[0025] Nano Co 2 o 3 Adding a magnetic field to the particles promotes the crystallization of KCl aqueous solution, and the volume fraction of 0.5% Co 2 o 3 Nanoparticles were mixed with 100 parts of KCl aqueous solution with a mass concentration of 25.5%, in order to make Co 2 o 3 Nanoparticles are uniformly suspended in KCl aqueous solution, a composite dispersant of sodium tripolyphosphate and triethanolamine is selected, the volume fraction of the dispersant is 0.45%, and then ultrasonic vibration is performed for 30 minutes to obtain a stable suspension of Co 2 o 3 -KCl-H 2 O cold storage material, the magnetic field strength during crystallization is 650Gauss, its nucleation supercooling degree is reduced by 57.3%, and the crystallization time is shortened by 52.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com