Synthesis method of ferrierite (FER) zeolite molecular sieve and obtained FER zeolite molecular sieve

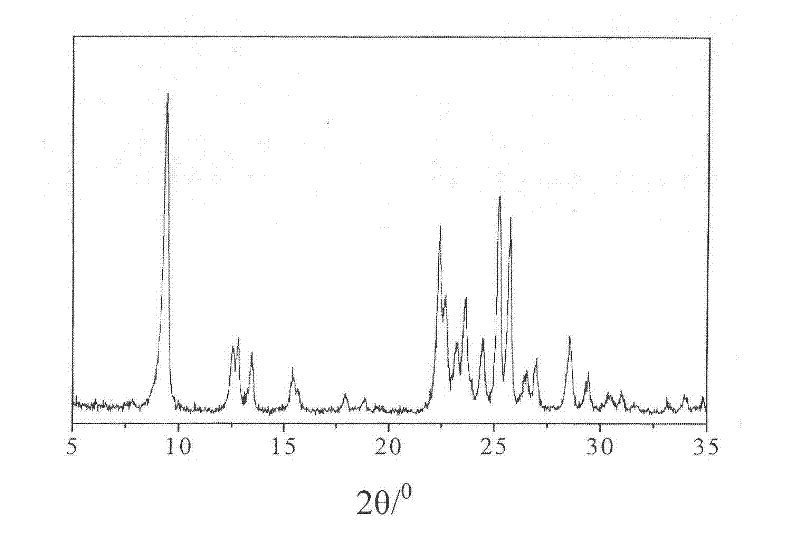

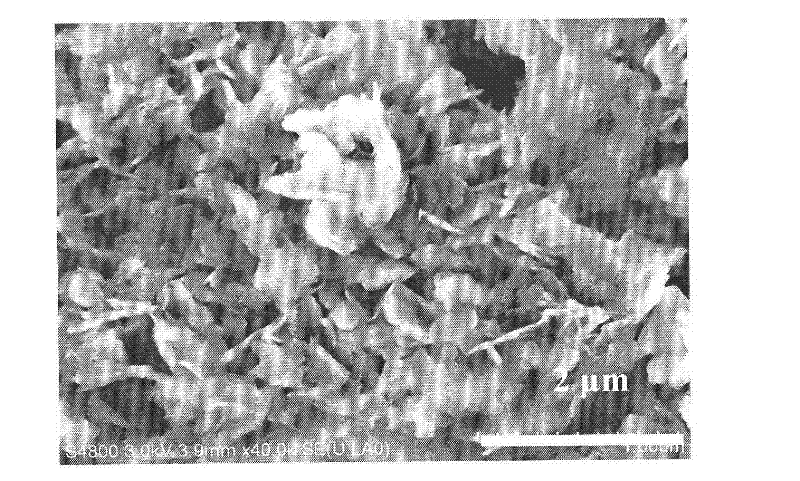

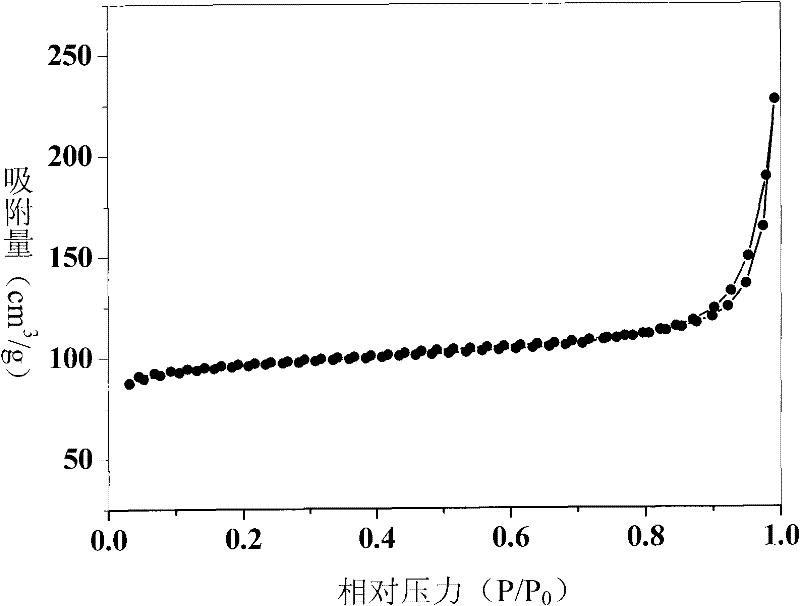

A technology of zeolite molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, iron conglomerate crystalline aluminum silicate zeolite, etc., can solve the problems of difficult crystallization, high price, long crystallization time, etc., and achieve low cost , short production process, high crystallinity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The synthesis method of FER zeolite molecular sieve:

[0042] (1) Al in the aluminum source according to the molar ratio 2 o 3 : SiO in silicon source 2 : MOH in alkali source: isopropylamine: pyrrolidine: H 2 O is 0.04: 1: 0.06: 0.4: 0.2: 18 feed intake, described aluminum source is aluminum nitrate, described silicon source is silica sol, and described alkali source is sodium hydroxide; Aluminum nitrate and sodium hydroxide Dissolve in deionized water, add silica sol while stirring, continue to stir for 1 hour until completely dissolved and mix evenly, then add mixed template agent while stirring, continue stirring for 1 hour to obtain a raw material mixture;

[0043] (2) The raw material mixture was hydrothermally crystallized at 180° C. for 72 hours under the condition of dynamic stirring at 500 rpm;

[0044] (3) The product after hydrothermal crystallization is filtered, washed, dried, and then calcined at 550° C. for 10 hours in an air atmosphere to obtain a F...

Embodiment 2

[0055] The synthesis method of FER zeolite molecular sieve:

[0056] (1) Al in the aluminum source according to the molar ratio 2 o 3 : SiO in silicon source 2 : MOH in alkali source: isopropylamine: pyrrolidine: H 2 O is 0.02: 1: 0.06: 0.4: 0.2: 18 feed intake, described aluminum source is aluminum nitrate, described silicon source is silica sol, and described alkali source is sodium hydroxide; Aluminum nitrate and sodium hydroxide Dissolve in deionized water, add silica sol while stirring, continue to stir for 1 hour until completely dissolved and mix evenly, then add mixed template agent while stirring, continue stirring for 1 hour to obtain a raw material mixture;

[0057] (2) Under the condition of dynamic stirring at 600rpm, the raw material mixture was hydrothermally crystallized at 180°C for 72 hours;

[0058] (3) The product after hydrothermal crystallization is filtered, washed, dried, and then calcined at 550° C. for 10 hours in an air atmosphere to obtain a FER...

Embodiment 3

[0064] The synthesis method of FER zeolite molecular sieve:

[0065] (1) Al in the aluminum source according to the molar ratio 2 o 3 : SiO in silicon source 2 : MOH in alkali source: isopropylamine: hexamethyleneimine: H 2 O is 0.01: 1: 0.06: 0.8: 0.2: 20 feed intake, the described aluminum source is aluminum nitrate, the described silicon source is silica sol, and the described alkali source is sodium hydroxide; Aluminum nitrate and sodium hydroxide Dissolve in deionized water, add silica sol while stirring, continue to stir for 1 hour until completely dissolved and mix evenly, then add mixed template agent while stirring, continue stirring for 1 hour to obtain a raw material mixture;

[0066] (2) Under the condition of dynamic stirring at 600rpm, the raw material mixture was hydrothermally crystallized at 160°C for 72 hours;

[0067] (3) The product after hydrothermal crystallization is filtered, washed, dried, and then calcined at 600° C. for 10 hours in an air atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com