Continuous long fiber reinforced thermoplastic polyurethane material and preparation method thereof

A technology of thermoplastic polyurethane and reinforced thermoplastic, which is applied in the field of continuous long fiber reinforced thermoplastic polyurethane material and its preparation, can solve the problems of weak interaction and inability to recycle parts, and achieve improved interface effect, simple structure, improved rigidity and The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

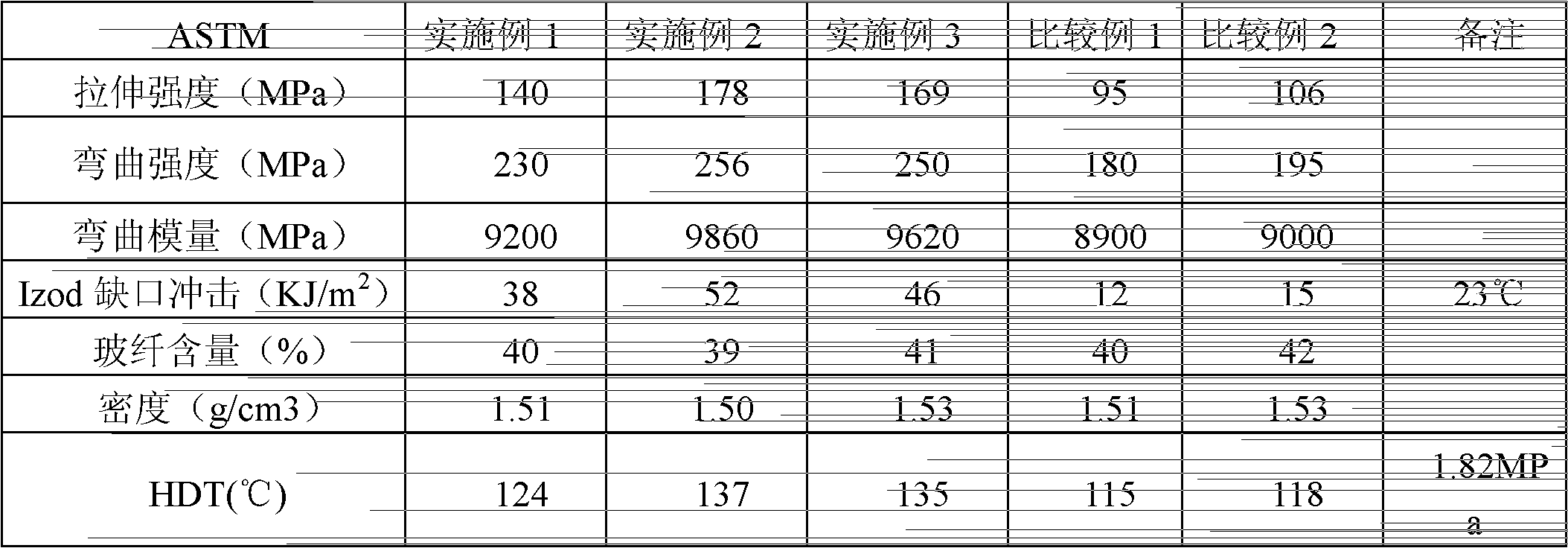

Embodiment 1

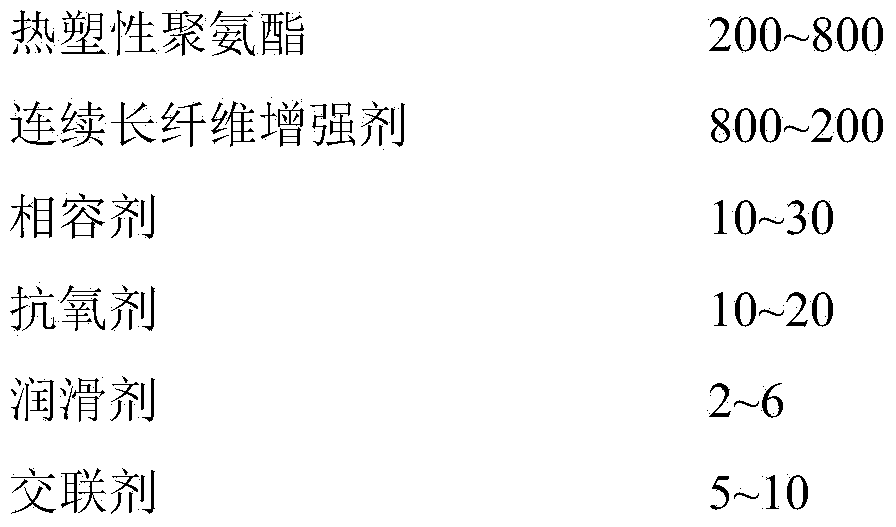

[0032] The invention provides a continuous long fiber reinforced thermoplastic polyurethane material, the polyurethane material has a cutting length of 11-13mm and a particle diameter of 2.0-4.0mm, comprising the following components and parts by weight:

[0033] Thermoplastic Polyurethane 600

[0034] Continuous glass fiber 400

[0035] Compatibilizer 10

[0036] Antioxidant 12

[0037] lubricant 5

[0038] Crosslinker 5

[0039] Described thermoplastic polyurethane is polyester polyurethane, and its Rockwell hardness is 110R;

[0040] The continuous long fiber reinforcing agent is continuous non-alkali glass fiber with a fiber diameter of 27 μm;

[0041] The compatibilizer is SMA resin (styrene-maleic anhydride resin), wherein the content of maleic anhydride is 0.5-1.5%;

[0042] Described antioxidant is antioxidant 1010 (tetra(beta-(3,5-di-tert-butyl-4 hydroxyphenyl) propionate) pentaerythritol ester), and antioxidant PEPQ (tetrakis(2,4- A mixture of di-tert-butylphe...

Embodiment 2

[0053] Thermoplastic Polyurethane 600

[0054] Continuous glass fiber 400

[0055] Compatibilizer 15

[0056] Antioxidant 12

[0057] lubricant 5

[0058] Crosslinker 10

[0059] Described thermoplastic polyurethane is polyester polyurethane, and its Rockwell hardness is 110R;

[0060] The continuous long fiber reinforcing agent is continuous non-alkali glass fiber with a fiber diameter of 27 μm;

[0061] The compatibilizer is SMA resin (styrene-maleic anhydride resin), wherein the content of maleic anhydride is 0.5-1.5%;

[0062] Described antioxidant is antioxidant 1010 (tetra(beta-(3,5-di-tert-butyl-4 hydroxyphenyl) propionate) pentaerythritol ester), and antioxidant PEPQ (tetrakis(2,4- A mixture of di-tert-butylphenol)-4,4'-biphenyl diphosphite), the weight ratio of the two is 1:2;

[0063] Described lubricant is pentaerythritol stearate (PETS);

[0064] The crosslinking agent used is triglycidyl isocyanurate (TGIC);

[0065] The continuous long fiber reinforced p...

Embodiment 3

[0074] Thermoplastic Polyurethane 600

[0075] Continuous glass fiber 400

[0076] Compatibilizer 15

[0077] Antioxidant 12

[0078] lubricant 5

[0079] Crosslinker 15

[0080] Described thermoplastic polyurethane is polyester polyurethane, and its Rockwell hardness is 110R;

[0081] The continuous long fiber reinforcing agent is continuous non-alkali glass fiber with a fiber diameter of 27 μm;

[0082] The compatibilizer is SMA resin (styrene-maleic anhydride resin), wherein the content of maleic anhydride is 0.5-1.5%;

[0083] Described antioxidant is antioxidant 1010 (tetra(beta-(3,5-di-tert-butyl-4 hydroxyphenyl) propionate) pentaerythritol ester), and antioxidant PEPQ (tetrakis(2,4- A mixture of di-tert-butylphenol)-4,4'-biphenyl diphosphite), the weight ratio of the two is 1:2;

[0084] Described lubricant is pentaerythritol stearate (PETS);

[0085] The crosslinking agent used is triglycidyl isocyanurate (TGIC);

[0086] The continuous long fiber reinforced p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com