Vacuum induction melting method of high-oxygen-content steel

A vacuum induction smelting technology with high oxygen content, which is applied in the field of vacuum induction smelting high oxygen content steel, can solve the problems that the cutting performance of the design composition cannot be truly reflected, achieve breakthroughs in technical bottlenecks, speed up the pace of development, and improve cutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Low-carbon, high-sulfur, high-oxygen AISI 1215 free-cutting steel is smelted in a vacuum induction furnace with a charging capacity of 80kg.

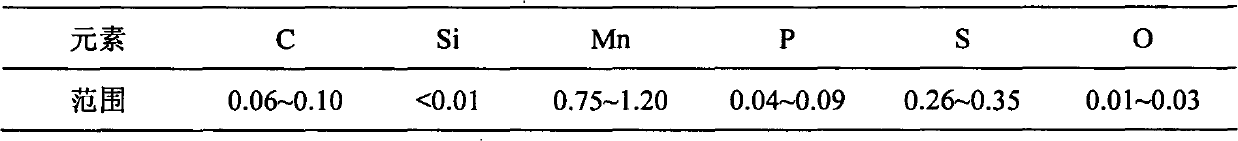

[0026] 1. Chemical composition of the target steel grade: (unit: wt%)

[0027]

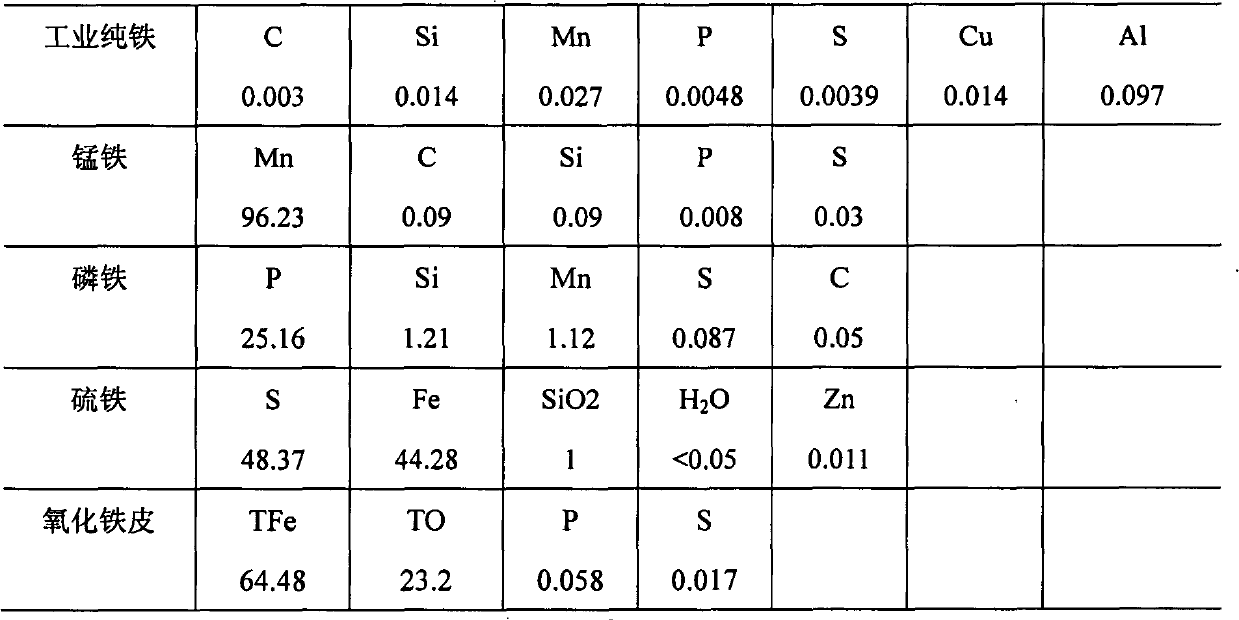

[0028] 2. Raw materials: (unit: wt%)

[0029]

[0030] 3. Specific operation steps:

[0031] 1) charging: put 78kg of industrial pure iron into the crucible;

[0032] 2) Vacuuming: After the vacuum degree is evacuated to 48Pa, it is filled with 5000Pa argon;

[0033] 3) Initial smelting: 78kg of industrial pure iron is induction smelted in the furnace until it is clear;

[0034] 4) Refining pre-decarburization: put 40g of iron oxide scale into the crucible, perform secondary vacuuming to make the vacuum degree reach 68Pa, and conduct induction refining for 8 minutes to remove a small amount of C, N and others in industrial pure iron Volatile impurity elements;

[0035] 5) Pre-oxygenation: After refining, fill the furnace with 5000Pa oxygen...

Embodiment 2

[0044] Low-carbon, high-sulfur, high-oxygen AISI 1215 free-cutting steel is smelted in a vacuum induction furnace with a charging capacity of 80kg.

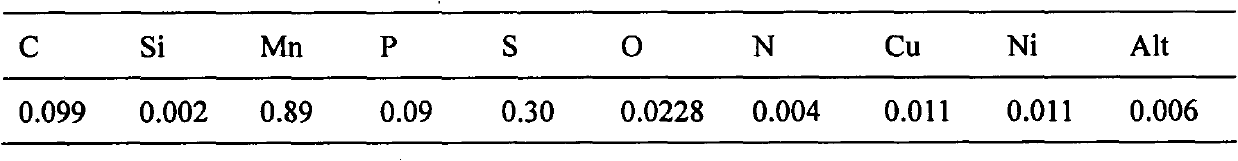

[0045] 1. Chemical composition of the target steel grade: (unit: wt%)

[0046]

[0047] 2. Raw materials: (unit: wt%)

[0048] Same as Example 1.

[0049] 3. Specific operation steps:

[0050] 1) charging: put 78kg of industrial pure iron into the crucible;

[0051] 2) Vacuuming: After the vacuum degree is evacuated to 48Pa, it is filled with 5000Pa argon;

[0052] 3) Initial smelting: 78kg of industrial pure iron is induction smelted in the furnace until it is clear;

[0053] 4) Refining pre-decarburization: put 40g of iron oxide scale into the crucible, perform secondary vacuuming to make the vacuum degree reach 68Pa, and conduct induction refining for 8 minutes to remove a small amount of C, N and others in industrial pure iron Volatile impurity elements;

[0054] 5) Pre-oxygenation: After refining, fill the furnace w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com