Rectangular plane cathode arc evaporation source of combination magnetic fields

An arc evaporation, flat cathode technology, applied in vacuum evaporation plating, circuits, discharge tubes, etc., can solve the problems of insufficient arc spot movement area, difficult to obtain flat shape, large splashed droplets, etc. Target utilization rate, convenient control, and effect of heat dispersion on the target surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

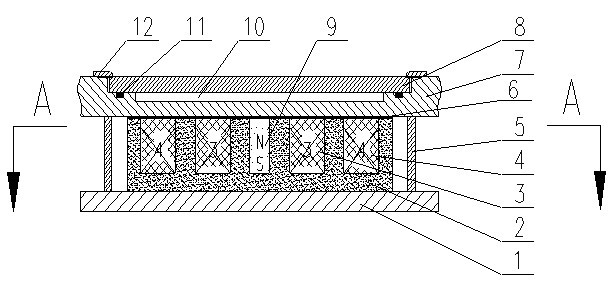

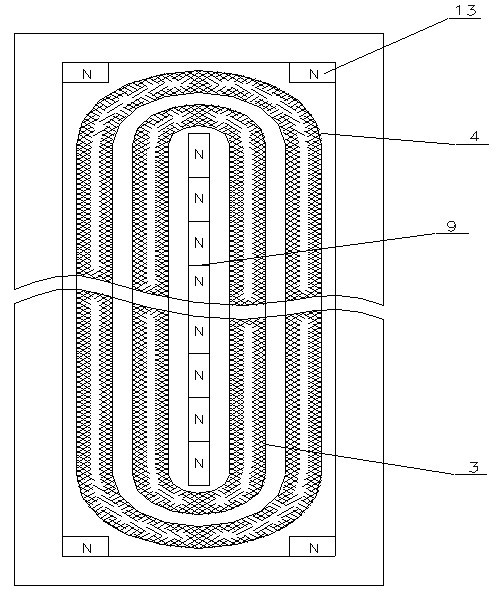

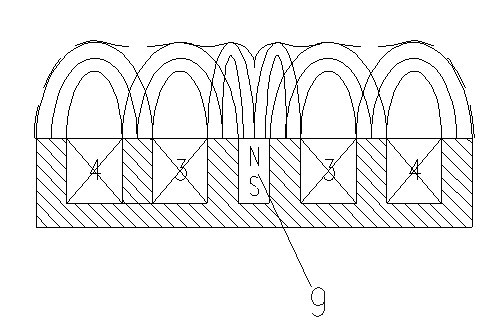

[0025] Such as figure 1 , 2 As shown, the rectangular planar cathodic arc evaporation source of the combined magnetic field of the present invention comprises a rectangular target plate 8, a cooling water tank plate 7, a magnetically conductive sheet 6, a magnetically conductive armature 2, a target base plate 1, a central axis permanent magnet 9, Four end angle permanent magnets 13, at least two oblong electromagnetic coils; the target base plate 1 supports the entire arc evaporation source, the target base plate 1 is provided with a magnetically conductive armature 2, and the magnetically conductive armature 2 faces one side of the target base plate 1 It is a plane, and the other side is convex and concave. Several grooves are provided on the upper surface of the magnetically conductive armature 2. The central axis permanent magnet 9, the end angle permanent magnet 13 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com