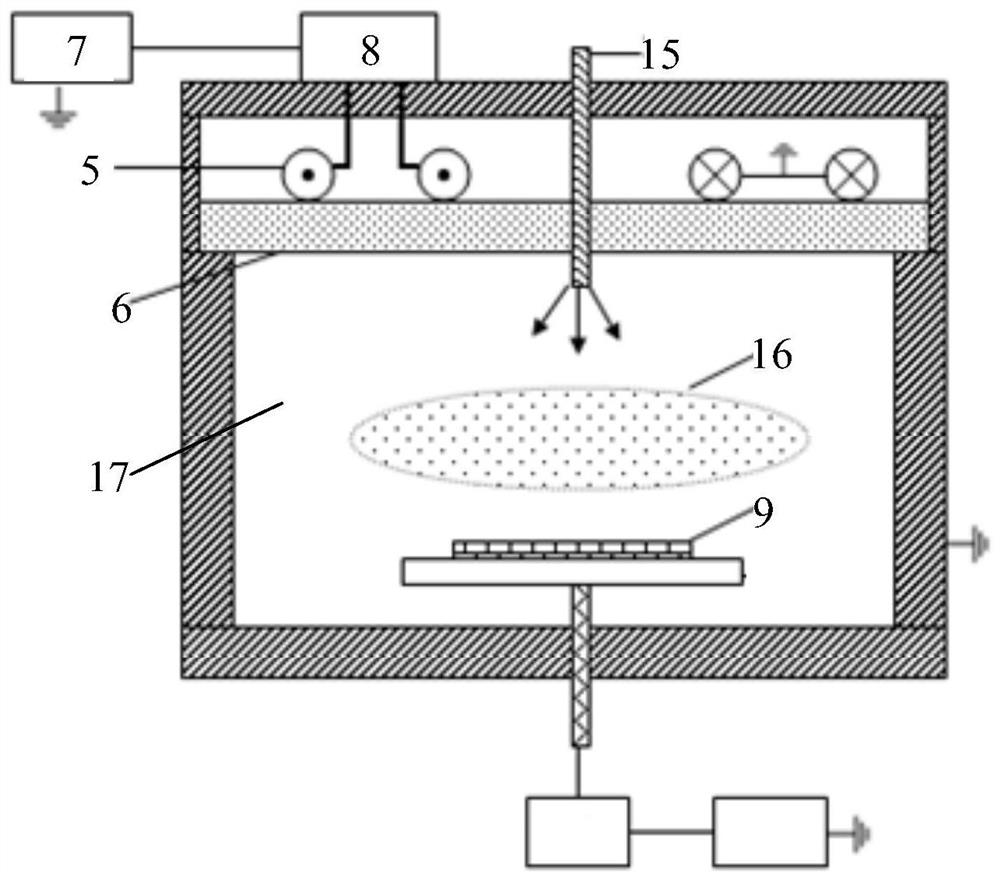

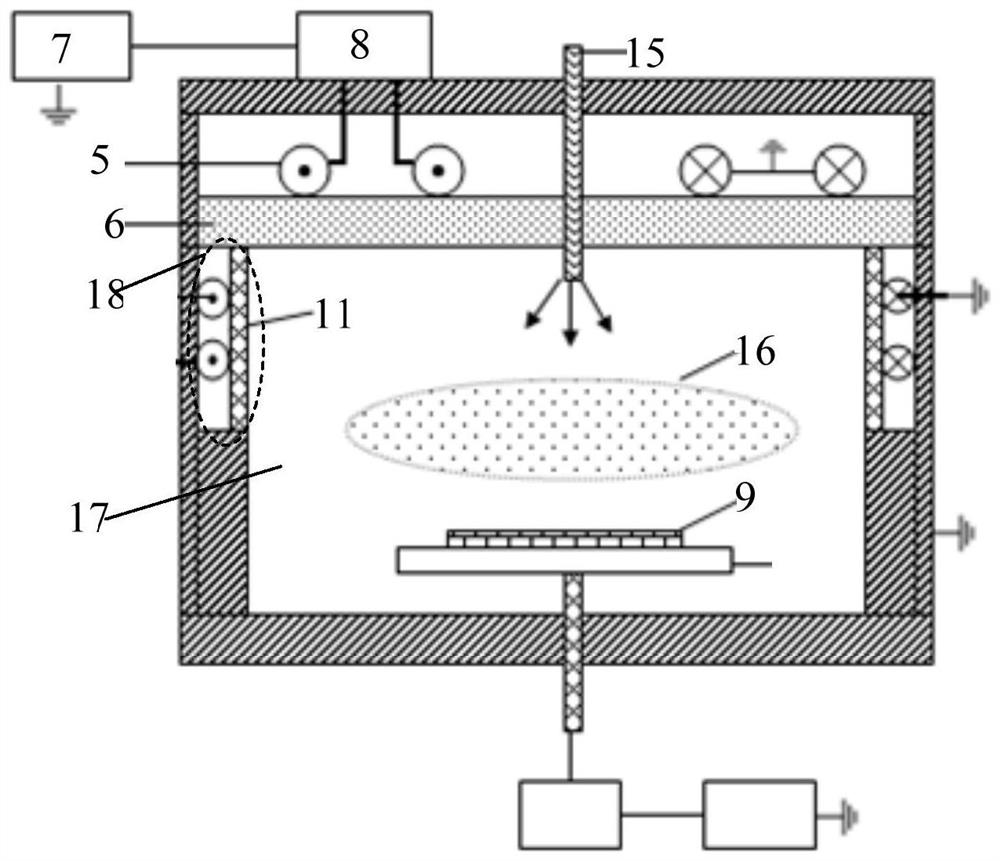

A coil, a dielectric cylinder and a plasma chamber

A plasma and chamber technology, applied in the field of plasma chambers, can solve problems such as insufficient plasma density, wafer surface damage, and slow etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

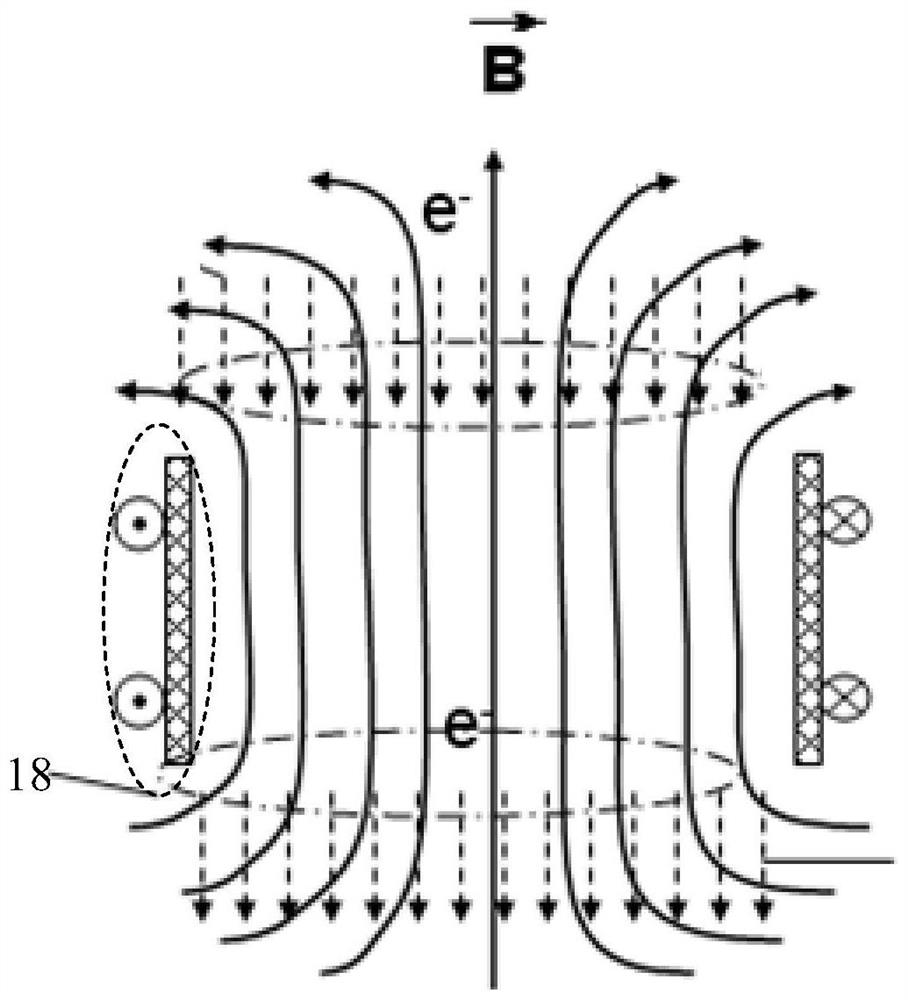

[0047] This embodiment provides a coil, such as Figure 4-Figure 7 As shown, including a solenoid 1 and a sub-coil 2 arranged on the solenoid 1, the angle between the axis of the sub-coil 2 and the axis of the solenoid 1 is greater than 0° and less than 180°, so that the magnetic field generated by the sub-coil 2 The magnetic field generated by the solenoid 1 has a different direction to increase the horizontal component of the magnetic field lines inside the solenoid 1 .

[0048] The coil is provided with a sub-coil 2 on the solenoid 1, and the angle between the axis of the sub-coil 2 and the axis of the solenoid 1 is greater than 0° and less than 180°, when the current is passed into the solenoid 1 and the sub-coil 2 , a magnetic field along its axial direction can be generated in the solenoid 1, and a magnetic field along its axial direction can be generated in the sub-coil 2 at the same time, the magnetic field generated in the solenoid 1 and the magnetic field generated i...

Embodiment 2

[0058] A coil is provided in this embodiment, and the difference from Embodiment 1 is, as Figure 8 As shown, the winding shape of the sub-coil 2 is semi-circular, and the sub-coil 2 of the same circle is located on the same side of its corresponding sub-core 3; the sub-coil 2 of two adjacent turns is located on different sides of its corresponding sub-core 3 . Correspondingly, the current directions in the two adjacent turns of the coil 2 are opposite.

[0059] Wherein, taking the sub-coil 2 wound on the solenoid 1 as two turns as an example, as Figure 9 As shown, the sub-coil 2 is first wound around the solenoid 1 once, and the coil 2 is located on the upper side of a coil core 3. After the coil 2 is wound, the wire of the coil 2 crosses to the phase The adjacent next circle of magnetic core 3, and wound to the lower side of the next circle of magnetic core 3. After the winding is completed, a current is passed into the wire, and the flow direction of the current in the ...

Embodiment 3

[0064] This embodiment provides a coil, which is different from Embodiment 1-2, such as Figure 10 As shown, the winding shape of the sub-coil 2 is circular, and the sub-coil 2 corresponds to winding the sub-magnetic core 3 once, and the current direction in two adjacent turns of the sub-coil 2 is the same.

[0065] Such setting can make the magnetic field formed by the sub-coil 2 in the position corresponding to the sub-magnetic core 3 in the solenoid 1 have a larger range, so that when the number of sub-magnetic cores 3 on the solenoid 1 and the number of distributed turns are the same, the sub-coil 2 The range of the magnetic field area where the magnetic field is generated in the solenoid 1 is correspondingly increased, thereby increasing the probability of the plasma whirling and colliding in the solenoid 1, and then effectively reducing the energy and temperature of the electrons in the plasma, and finally The damage to the wafer surface after the electrons bombard the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com