Preparation method of polymeric dispersant for papermaking

A technology of dispersant and regulator, applied in fiber dispersant addition, paper, etc., can solve the problems of large dosage of alcohol, long production cycle and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

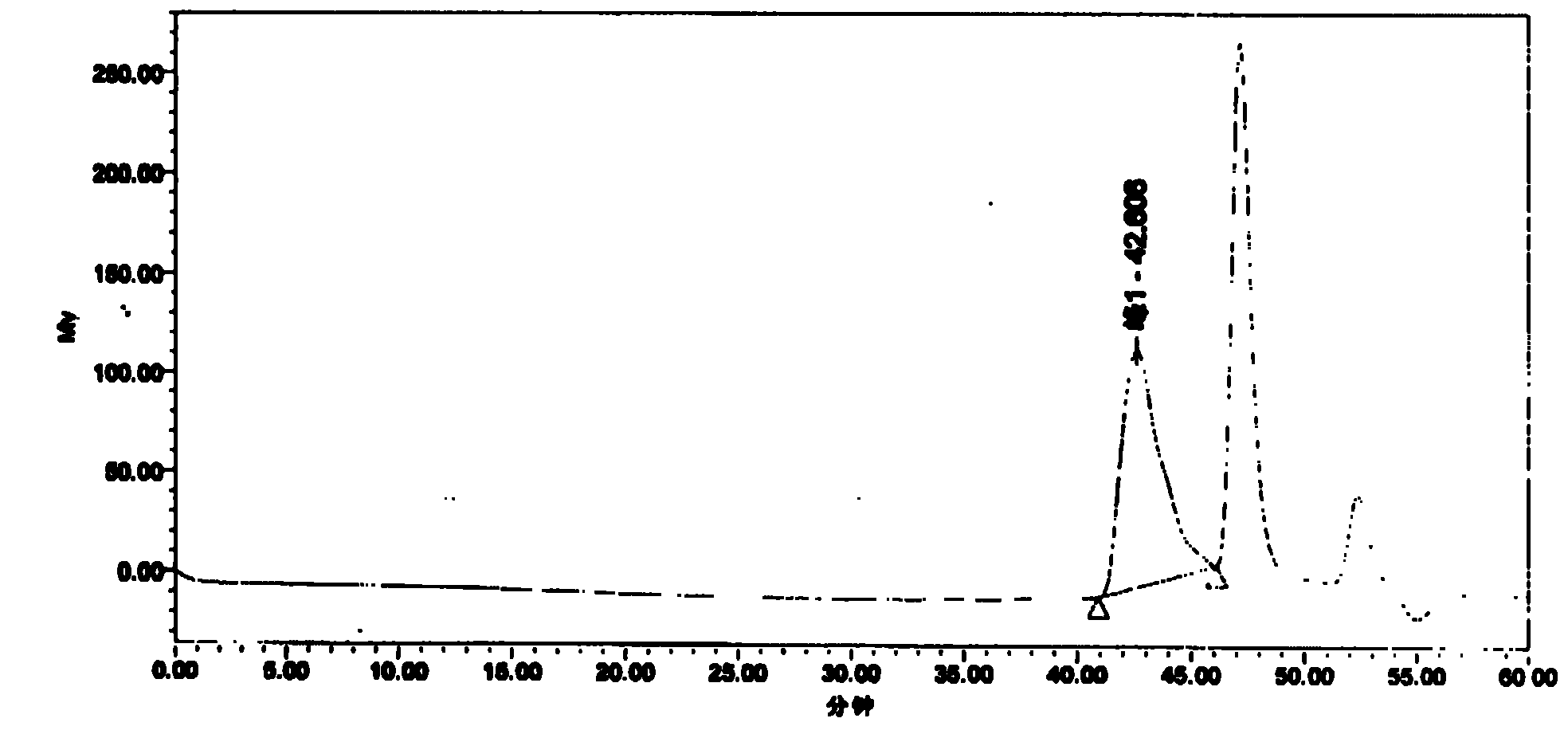

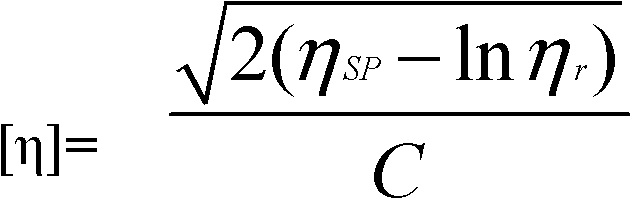

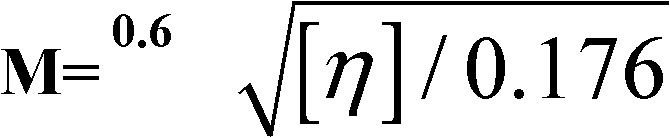

Image

Examples

preparation example Construction

[0021] The invention discloses a preparation method of a dispersant for papermaking, comprising the following steps:

[0022] Add acrylic acid and ammonium persulfate solution dropwise to the sodium bisulfite solution at 65-90 °C, respectively, and obtain a mixed solution after heat preservation;

[0023] Hydroquinone is added to the mixed solution, cooled to 40-50° C., and the pH value is adjusted to 7-8 with a pH value adjuster to obtain a dispersant for papermaking.

[0024] In the preparation process of the above-mentioned dispersant for papermaking, the present invention uses acrylic acid as a polymerization monomer, sodium bisulfite as a chain transfer agent, hydroquinone as a polymerization inhibitor, and ammonium persulfate as an initiator, and then uses pH value adjustment A low molecular weight sodium polyacrylate dispersant is obtained by adjusting the pH value of the agent. Sodium bisulfite first reacts with ammonium persulfate to generate free radicals, and then ...

Embodiment 1

[0048] Take a four-necked flask and place it in a water bath. In the four-necked flask, place two separatory funnels in two ports, a thermometer in one port to control the temperature, and a stirrer in the other port for stirring the liquid.

[0049] Dissolve 16.5g of ammonium persulfate in 100g of water to obtain an ammonium persulfate solution, and continue to put the ammonium persulfate solution and 270g of acrylic acid into two separatory funnels of the four-necked flask respectively;

[0050] Dissolve 12.5g of sodium bisulfite in 245g of water and add it to the bottom of the four-necked flask;

[0051] Adjust the temperature of the water bath to 80°C, turn on the stirrer and start stirring. When the temperature rises to 65°C, start to add acrylic acid and ammonium persulfate solution dropwise at the same time, and ensure that both dropwise addition ends at the same time. The dropwise addition time is about 2 hours. After the dropwise addition, the temperature was kept at ...

Embodiment 2

[0055] Take a four-necked flask and place it in a water bath, two separatory funnels are placed in two ports of the four-necked flask, a thermometer is placed in one port to control the temperature, and a stirrer is placed in the other port for stirring the liquid;

[0056] 16.5g of ammonium persulfate was dissolved in 100g of water to obtain an ammonium persulfate solution, and the ammonium persulfate solution and 280g of acrylic acid were continuously put into two separatory funnels of the four-necked flask respectively;

[0057] Dissolve 16.5g of sodium bisulfite in 231g of water and add it to the bottom of the four-necked flask;

[0058] Adjust the temperature of the water bath to 80°C, turn on the stirrer and start stirring. When the temperature rises to 65°C, start to add acrylic acid and ammonium persulfate solution dropwise at the same time, and ensure that both dropwise addition ends at the same time. The dropwise addition time is about 2 hours. After the dropwise add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com