Reflective airy ring diffraction grating

A diffraction grating and reflective technology, which is applied in the field of optical components, can solve problems that have not yet been discovered, and achieve the effects of improving uniformity and boundary sharpness, improving precision, and suppressing diffraction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

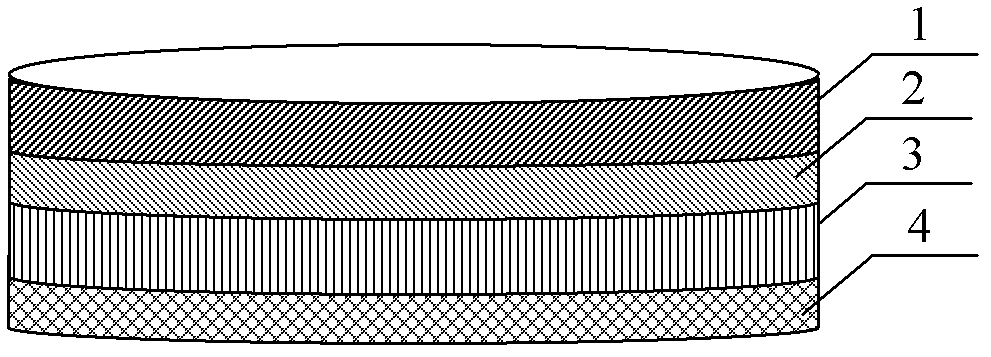

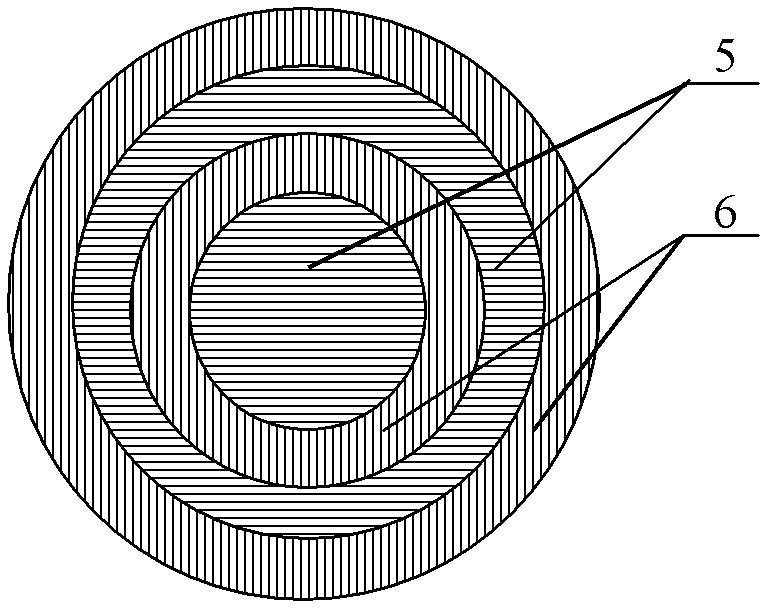

[0014] Describe in detail below in conjunction with embodiment and with reference to accompanying drawing: see figure 1 and figure 2 , the reflective Airy ring diffraction grating has a laminated structure, from bottom to top there are substrate layer 4, metal reflective film layer 3, semi-transparent and semi-reflective film layer 2 and anti-reflective film layer 1, wherein the metal reflective film layer 3. It is composed of two different metal reflective films 5 and 6 that are paired one by one, and are assembled in a circular and coaxial annular manner. The refractive index of the semi-transparent and semi-reflective film layer is between that of the paired two metal reflective film layers. rate between.

[0015] Said metal reflective film layer 3 is composed of any two reflective films in gold, silver, copper, aluminum and chromium.

[0016] Said transflective film layer 2 is any one of magnesium fluoride film layer, magnesium chloride film layer or zinc sulfide film l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com