Polycrystalline silicon processing method

A polysilicon, silicon oxynitride technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as surface defects and wafer process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

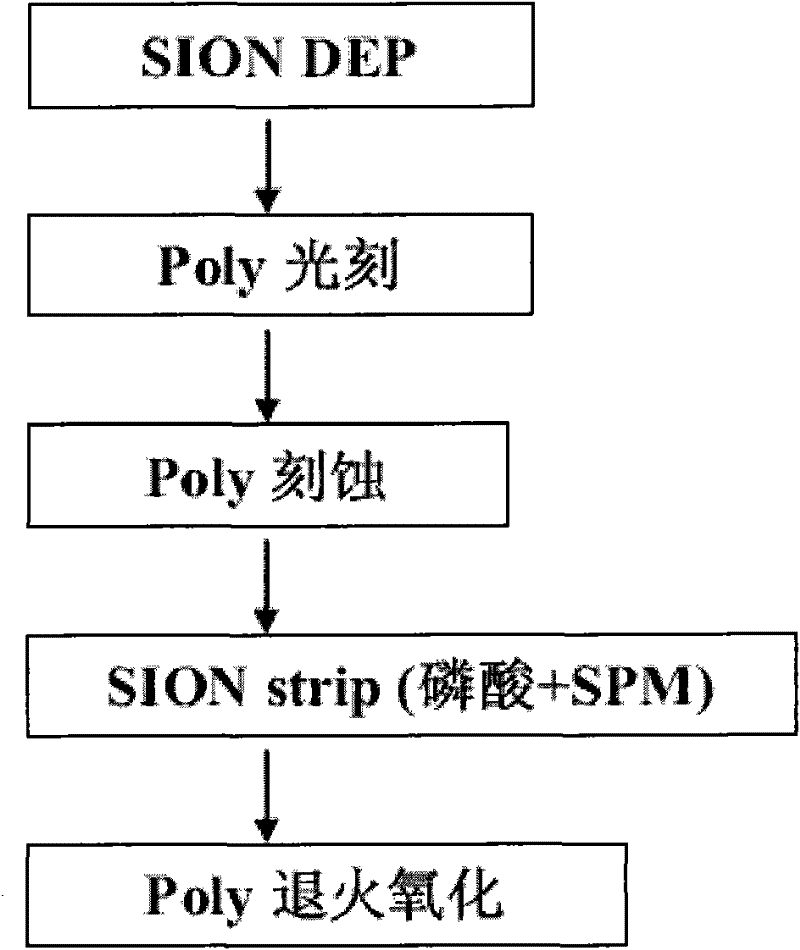

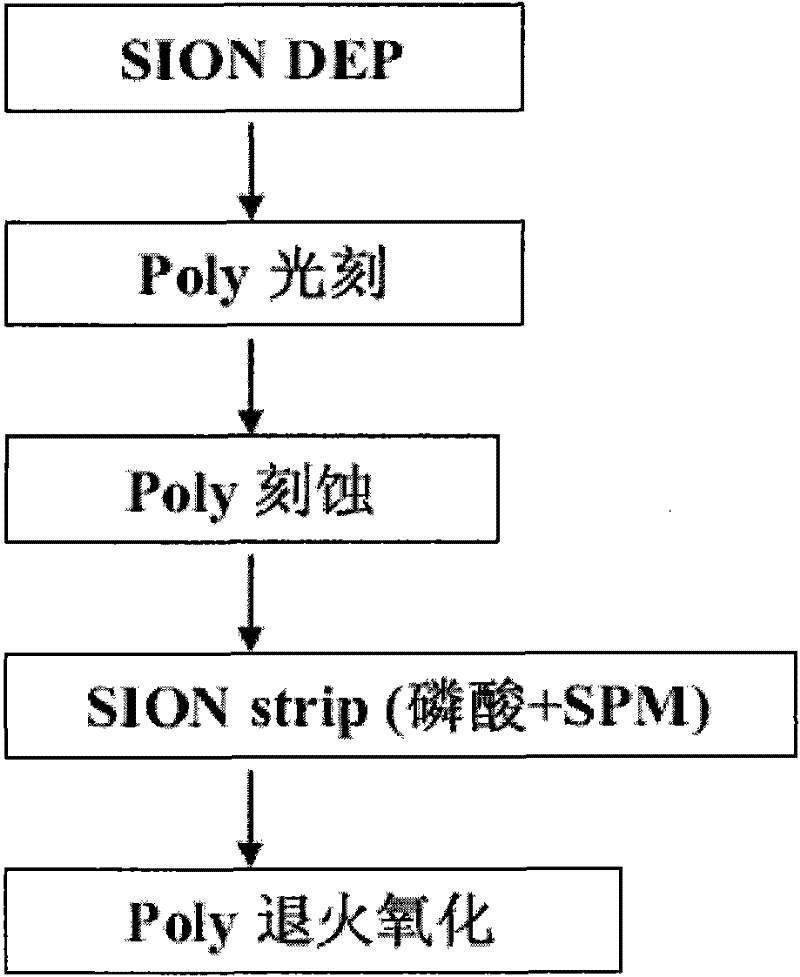

[0009] Please refer to figure 1 As shown, the present invention provides a polysilicon process method, which includes the following steps: SiON DEP. ), SiON Strip (i.e. silicon oxynitride removal) and Poly annealing oxidation (i.e. polysilicon annealing oxidation)

[0010] The SiON DEP. process (that is, silicon oxynitride deposition) is to cover SiON (silicon oxynitride) on the surface of polysilicon by chemical vapor deposition (Chemical Vapor Deposition) to form an anti-reflection layer (ARC), In this way, the reflectivity of the polysilicon surface during photolithography is reduced, and at the same time, the resolution of the photolithographic pattern is improved, making the photolithography more accurate.

[0011] The Poly photolithography (i.e. polysilicon photolithography) process is to coat a thin layer of photoresist on the surface of polysilicon, and use a mask to irradiate the photoresist, so that the photoresist in some areas is exposed to light, and after develo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com