Multi-section-type FP (FabryPerot) cavity single wavelength laser based on deeply etched grooves

A deep etching, laser technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problem of device wavelength deviation from the design wavelength, etc., and achieve the effect of narrow laser line width, less energy loss, and small manufacturing error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

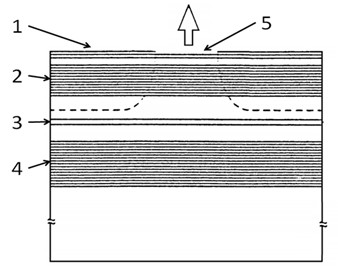

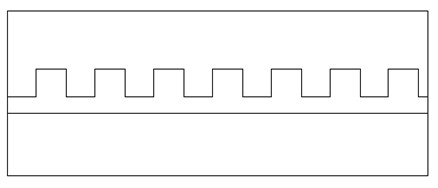

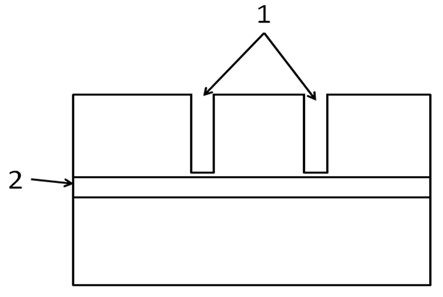

[0028] Figure 4 It is an embodiment of the present invention, and its structure includes a laser waveguide 11, a first deeply etched reflection surface 21, a second deeply etched reflection surface 22 and an array of deeply etched grooves 31 distributed therebetween.

[0029] The deep etched groove array 31, the first deep etched reflective surface 21 and the second deep etched reflective surface 22 are the key structures of the present invention, wherein the deep etched groove array 31 includes the first deep etched groove 301, the second deep etched groove 302 and the 0~4 deep etched grooves between them. The above structures are all fabricated by the ICP deep etching process, which requires smooth and vertical sidewalls and an etching depth exceeding the quantum well layer 5 to ensure sufficient feedback and to ensure that most of the energy in the cavity propagates in the direction of the horizontal and resonant cavity. When the light passes through the side of the deep ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com