Method for automatically dismounting electronic device on abandoned printed circuit board by using industrial waste gas

A technology of electronic components and industrial waste gas, which is applied in the field of comprehensive utilization of electronic waste resources, can solve the problems of being unsuitable for large-scale industrial production, increasing the difficulty of the processing process, and high cost, achieving pollution-free automatic disassembly, reducing processing costs, value-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with specific embodiments.

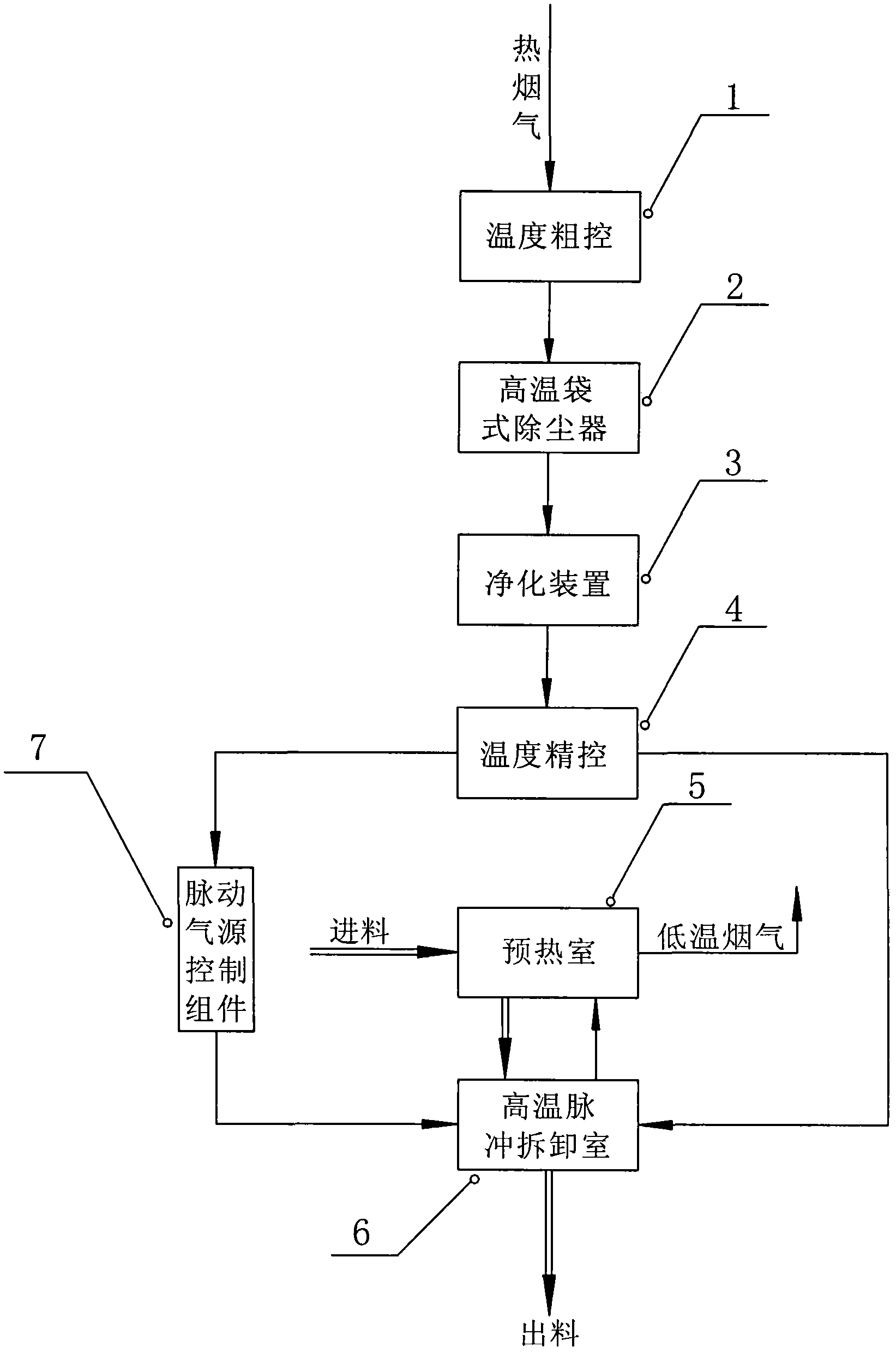

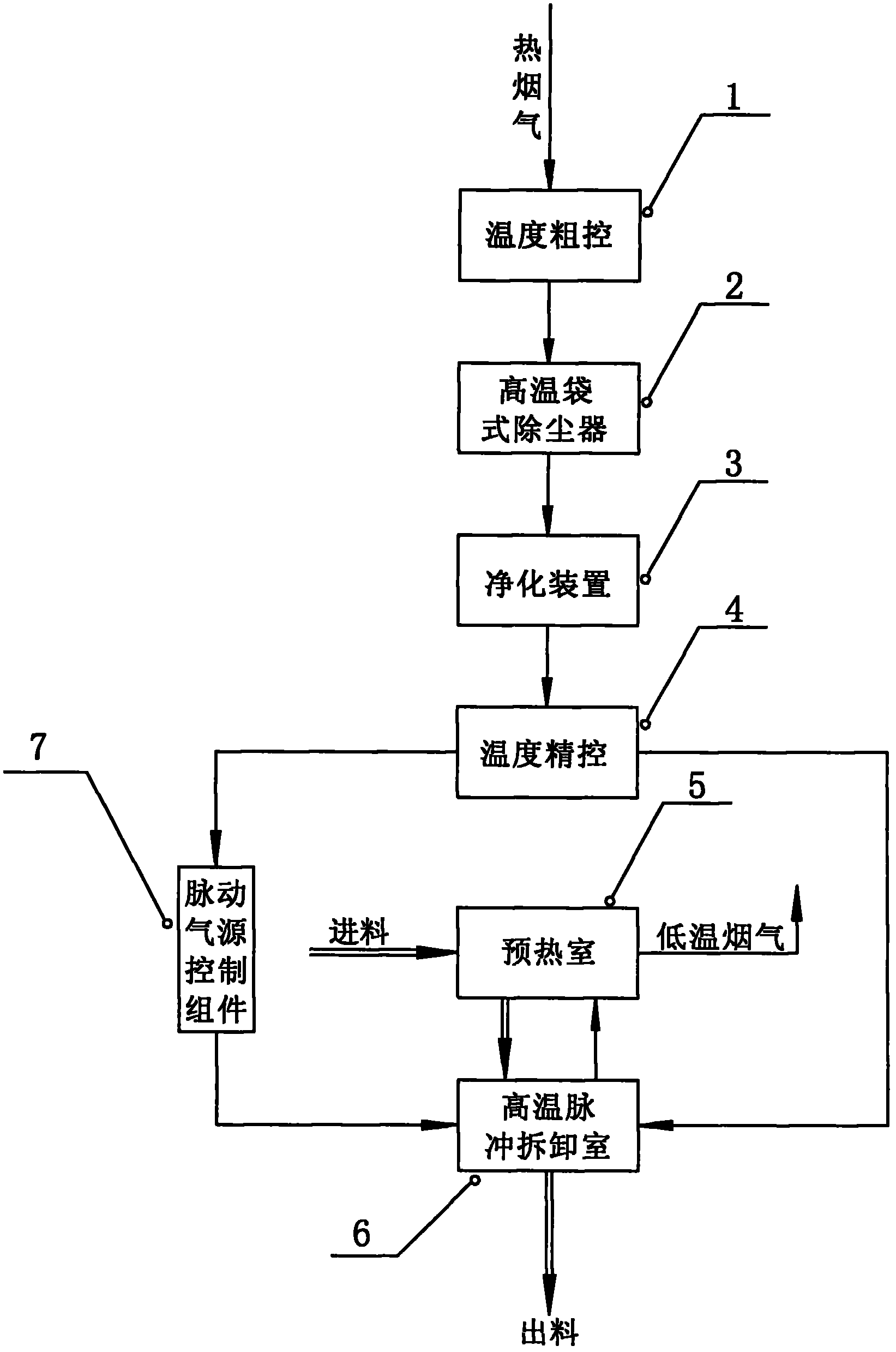

[0021] Such as figure 1 Shown is the process flow chart of the present invention. The industrial waste gas passes through the temperature rough control device 1, and the flue gas after the temperature adjustment treatment (the temperature is controlled at 250 ℃ ~ 350 ℃) is dedusted and purified through the high temperature bag filter 2 and the purification device 3, and the industrial waste gas after dust removal and purification passes through the The temperature precision control device 4 carries out further temperature control, the temperature is controlled at 223-233°C, and a part (70%-90%) of the precisely controlled flue gas is directly introduced into the high-temperature pulse disassembly chamber 6, and then the flue gas is mixed with the waste printing The direction opposite to the running direction of the circuit board flows into the preheating chamber 5, and t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap