Treatment method of landfill leachate

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve problems such as high operating costs and difficult treatment of deammonization tail gas, and achieve the effect of reducing production costs and reducing the amount of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

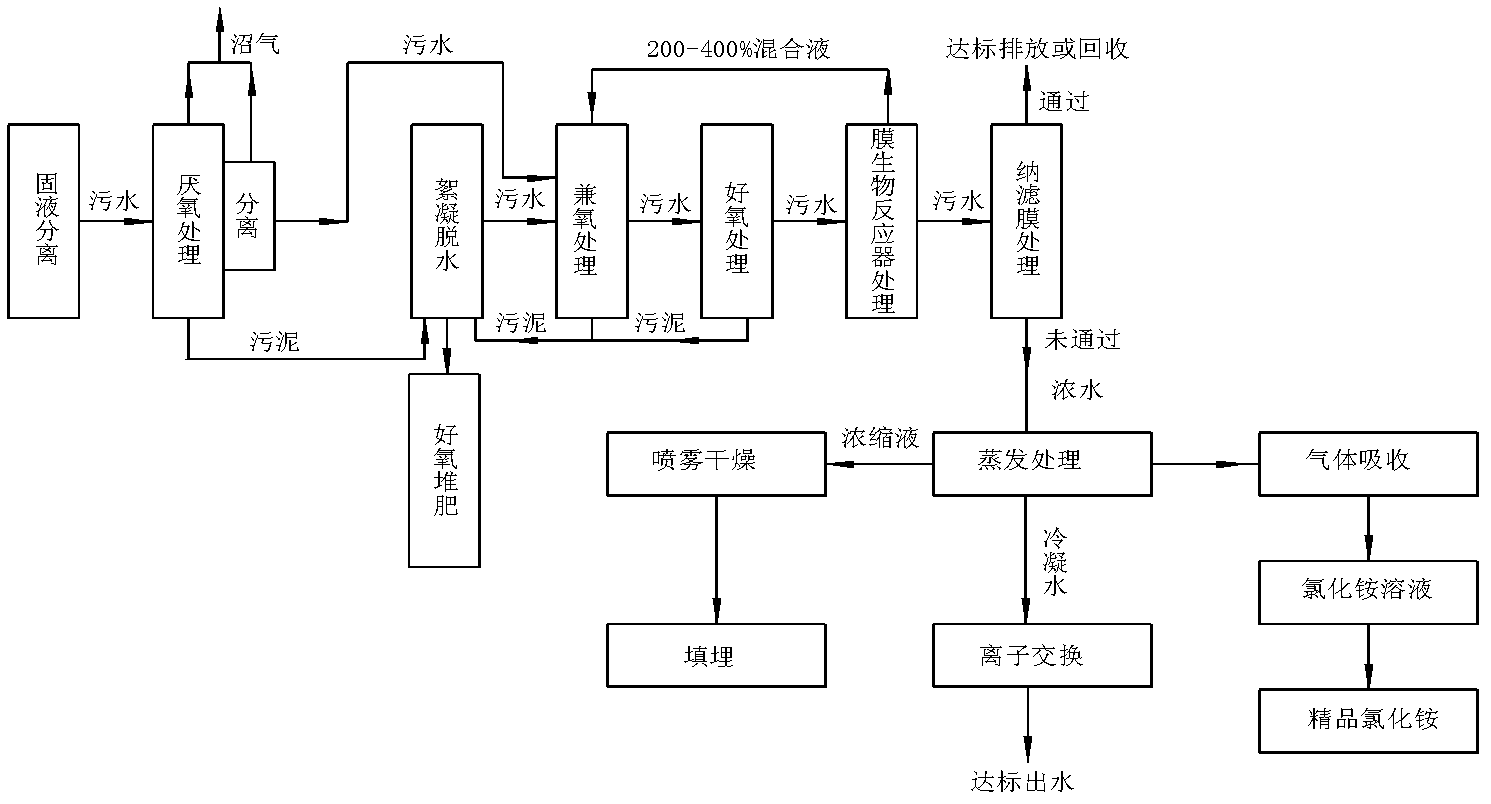

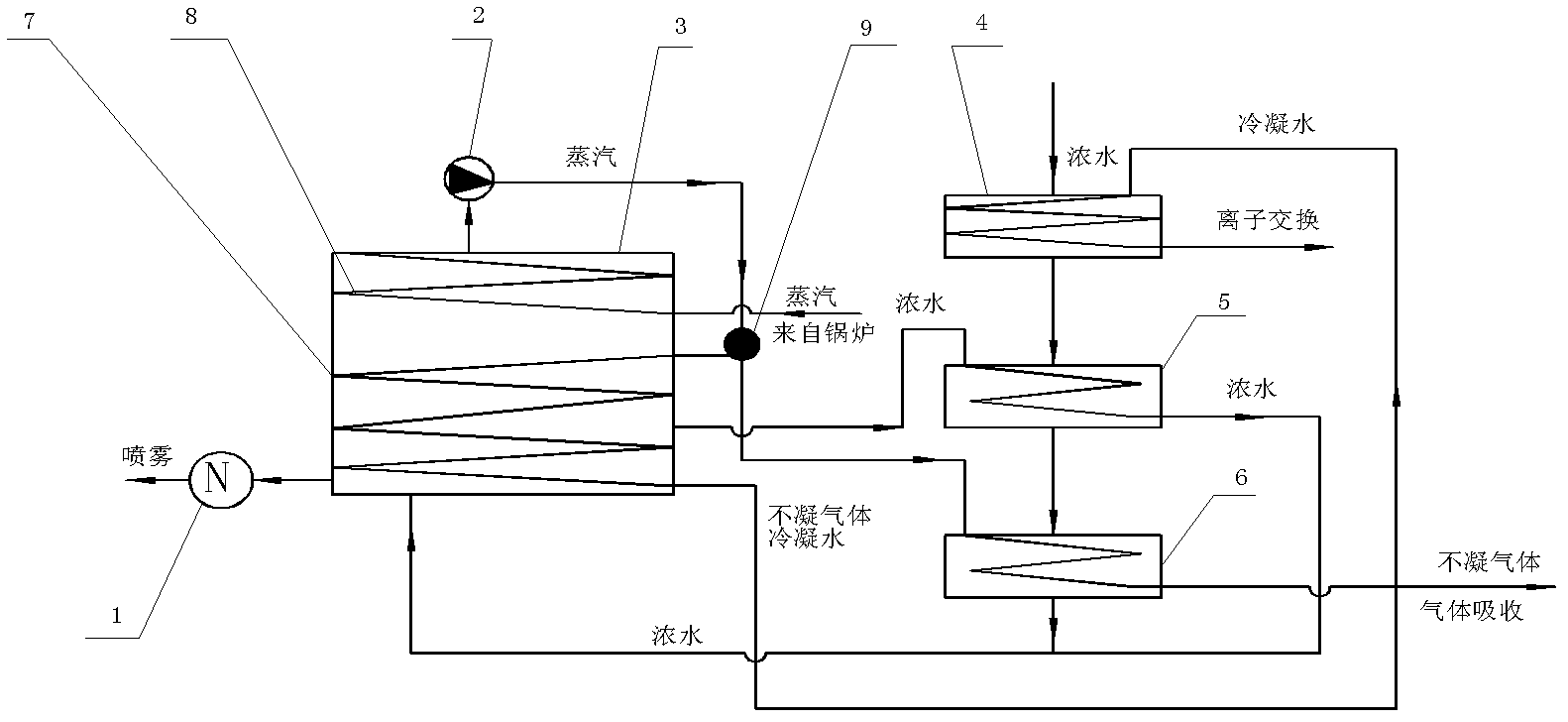

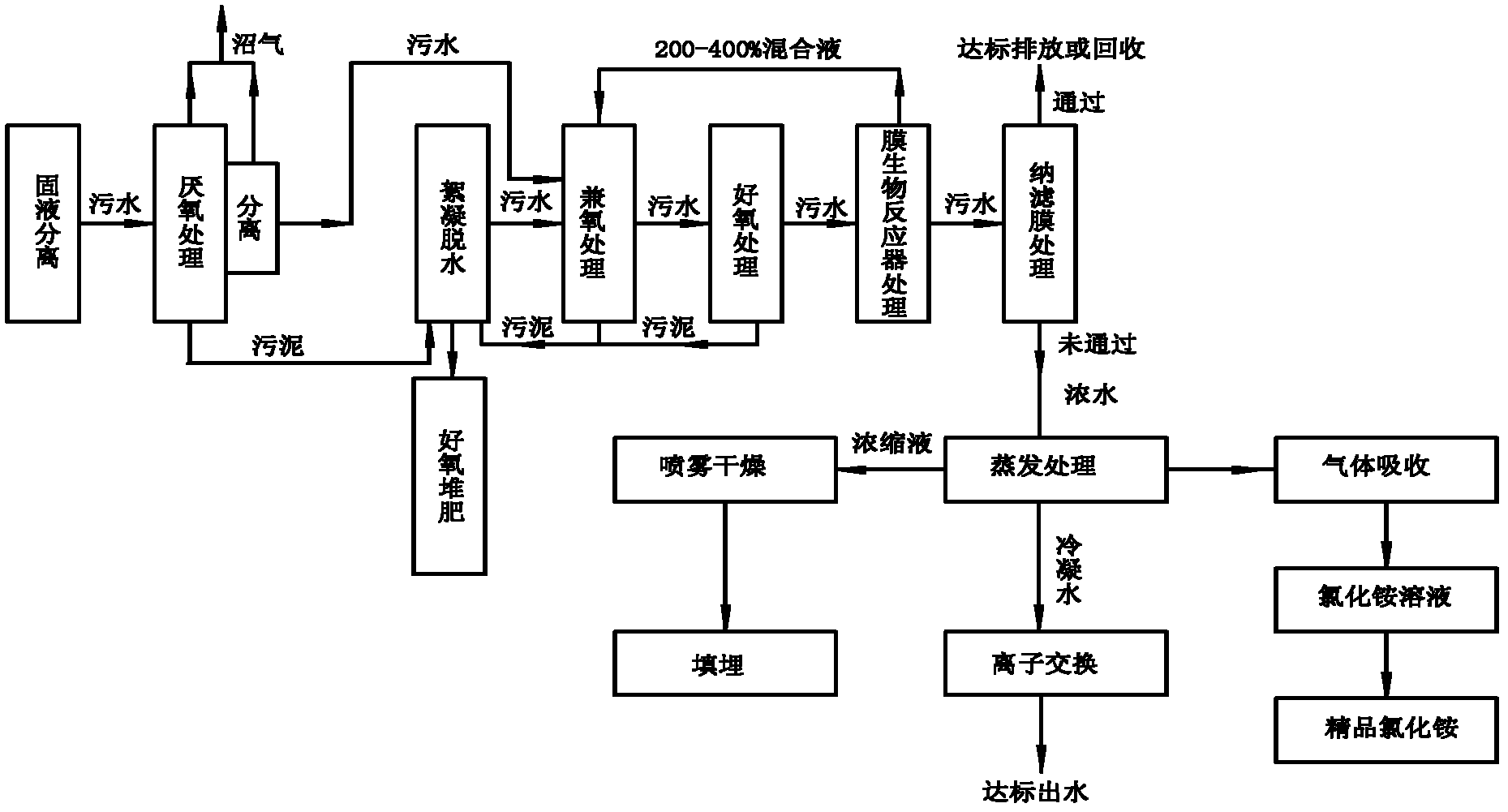

[0037] The following combination figure 1 and figure 2 , the processing method of landfill leachate of the present invention is described in detail:

[0038] (A) Solid-liquid separation: first pass the leachate through a 10mm grid to remove the floating and bulky substances, and the floating and bulky substances are sent to the landfill for harmless landfill treatment in a closed garbage truck , the sewage obtained is sent to step (B) for processing;

[0039] (B) Anaerobic treatment of sewage: the sewage obtained in step (A) is metered and sent to an anaerobic reactor, and the anaerobic treatment equipment includes an anaerobic reactor and a separation system. The anaerobic reactor is equipped with anaerobic sludge, the content of anaerobic sludge in the sewage is more than 30,000-40,000 mg / liter (weight / volume ratio), and the volume load of chemical oxygen consumption is 15-25kg / m 3 d. The anaerobic reactor is equipped with a stirrer, and the stirring speed is 30-50 rpm,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com