Seawater desalination process method for source water pretreatment by using biological method

A process method and pretreatment technology, applied in biological water/sewage treatment, energy wastewater treatment, seawater treatment, etc., can solve the problems of increasing the cost of seawater desalination, reducing the service life of the membrane group, and ineffective effect, and achieves a feasible The effect of sustainable development, prolonging service life and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

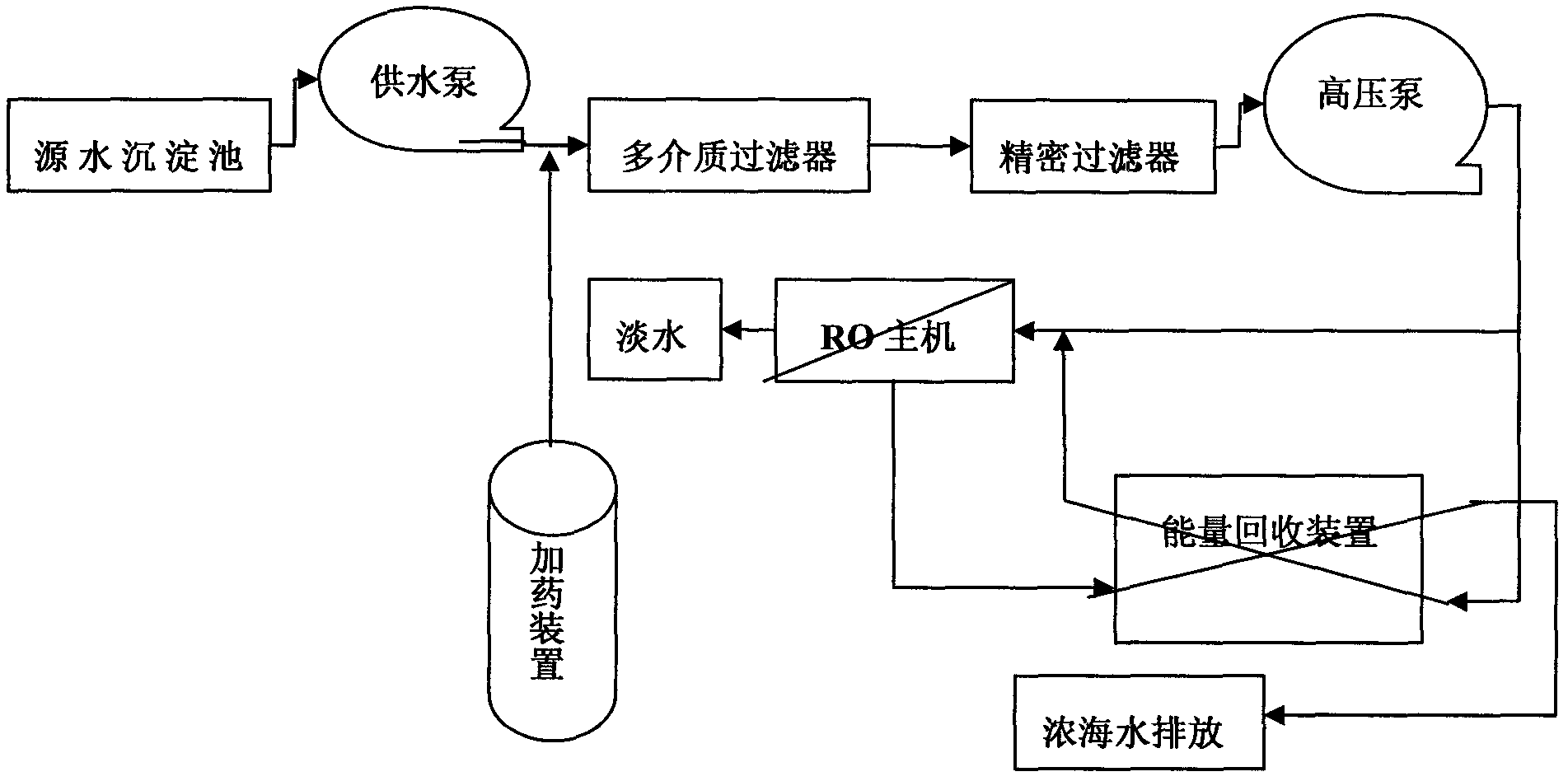

[0034] as attached figure 1 Shown is the traditional reverse osmosis (SWRO) seawater desalination process, which uses chemical agents for seawater pretreatment. The pretreatment system mainly includes pretreatment dosing devices, mechanical filtration, ion wells, and precision filtration; traditional Pretreatment methods include sterilization, sedimentation, filtration, softening and degassing, etc.; not only the treatment effect is not good, but also need to add various chemicals to kill various microorganisms and the reproductive cells and eggs of some marine organisms, etc., to prevent These substances scale and multiply on the reverse osmosis membrane, which ultimately affects the treatment capacity and effect of the reverse osmosis membrane; and these chemicals will eventually be discharged into the ocean after the seawater desalination treatment process is completed, causing damage to the marine environment Impact.

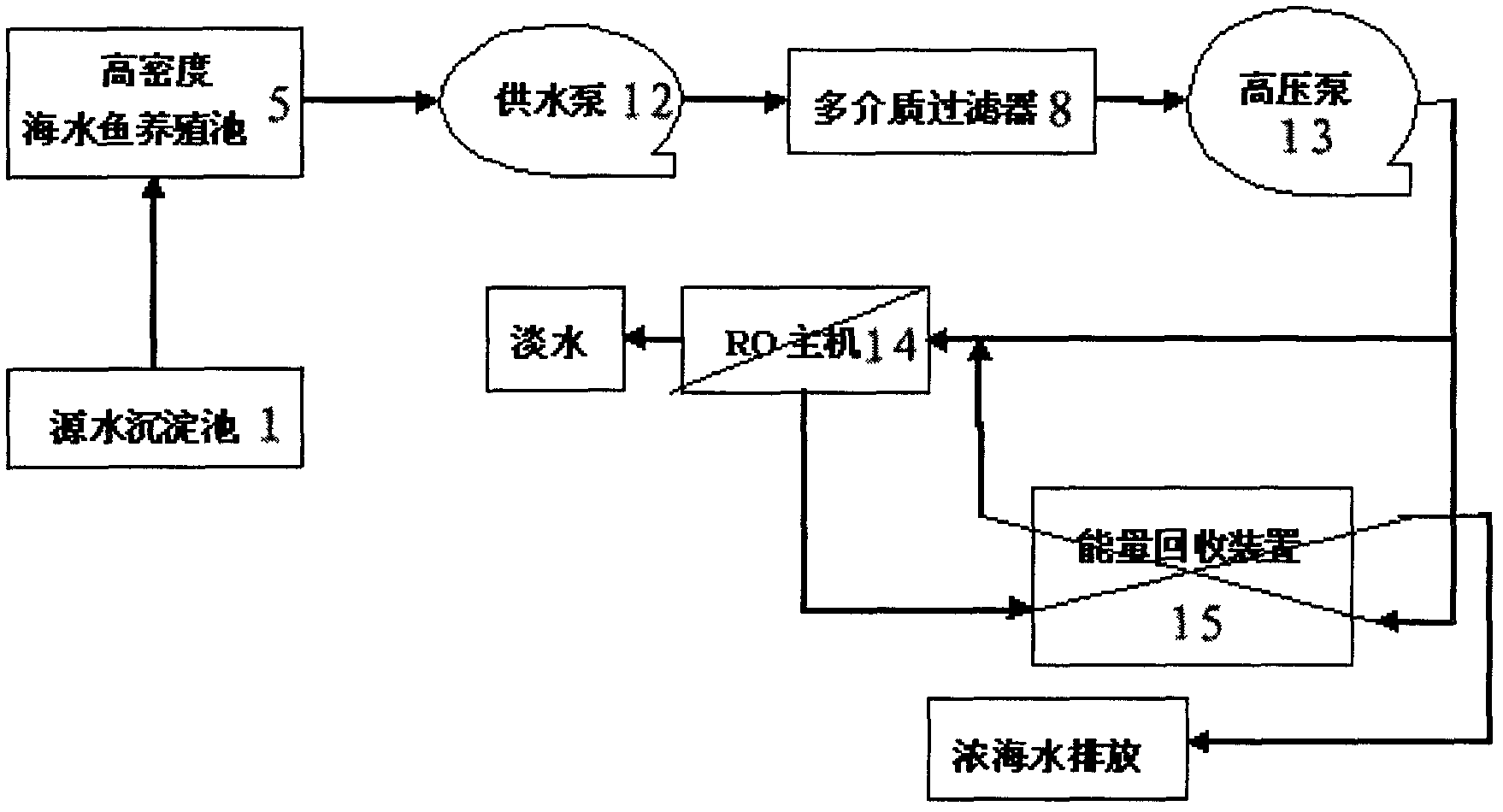

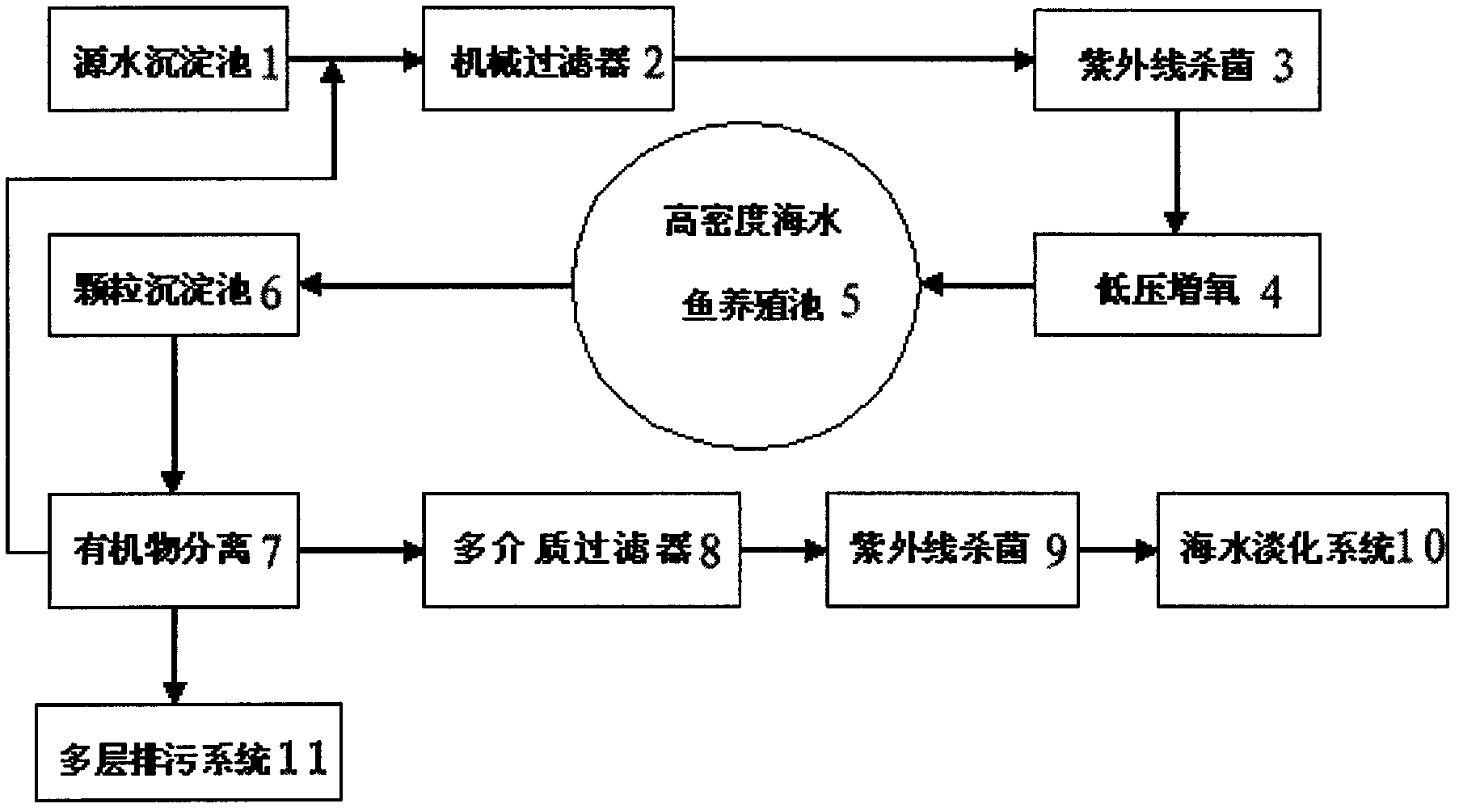

[0035] The embodiment of the present invention provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com