Hydroxyapatite hollow micro-carrier material and preparation method thereof

A technology of hydroxyapatite and carrier materials, applied in biochemical equipment and methods, tissue cell/virus culture devices, biochemical instruments, etc., can solve the problems of difficult removal of force, unfavorable immersion, etc., and achieve dense and uniform HA. Good cell adhesion, low material density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Take the hollow glass microspheres in the middle of the two meshes sieved with 100 mesh and 140 mesh sieves, then clean them with deionized water, and place them in a blast drying oven until dry after cleaning.

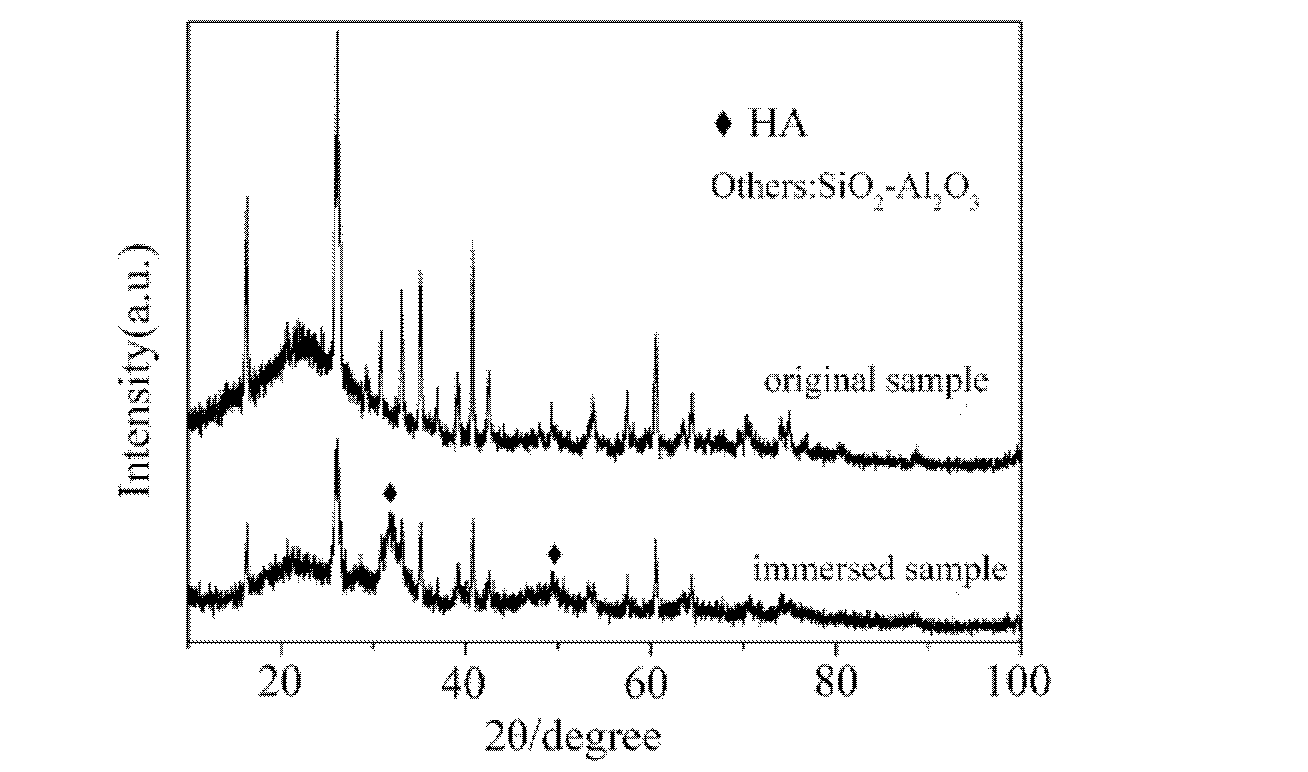

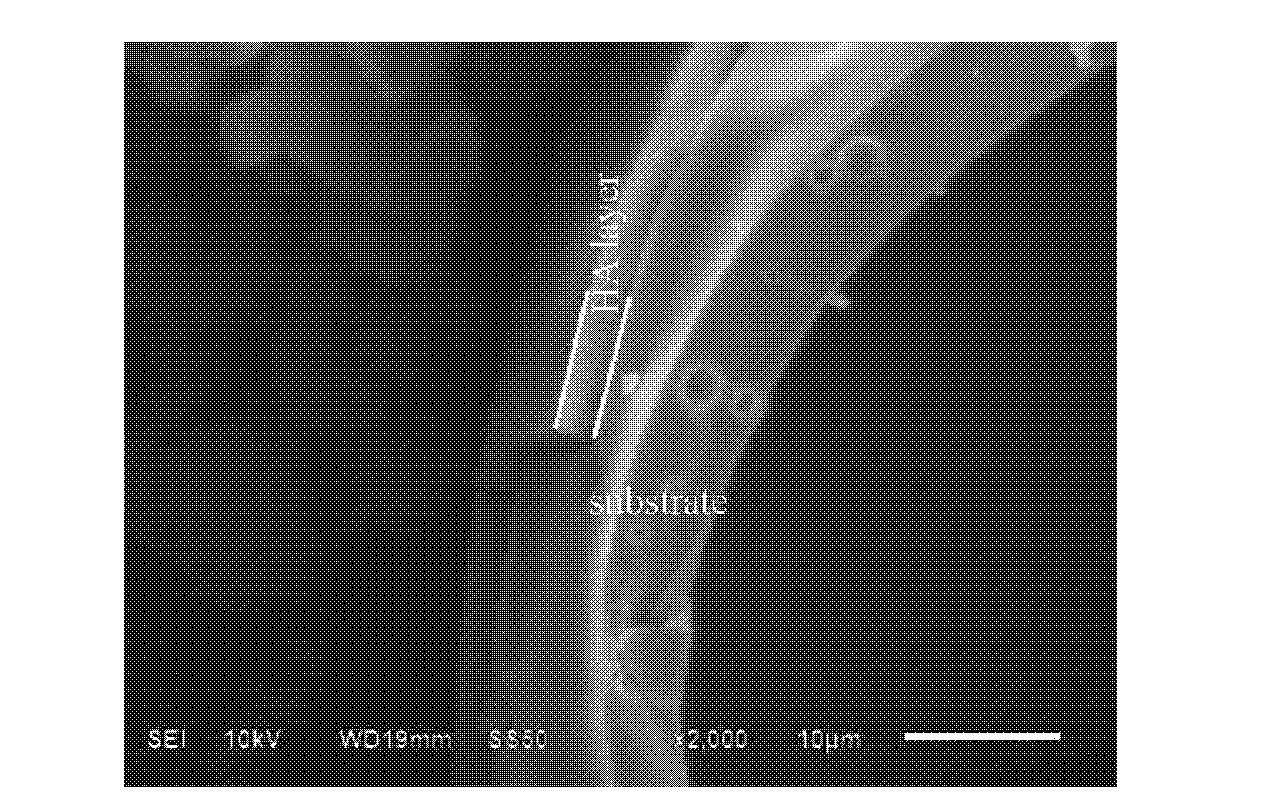

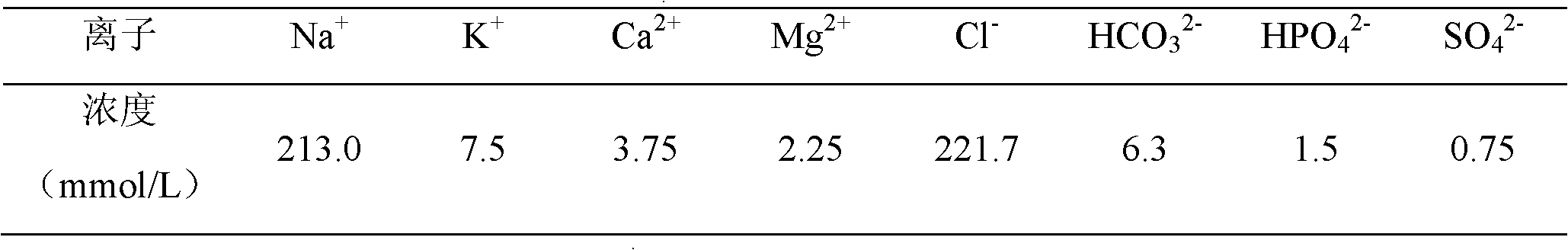

[0024] (2) Immerse the hollow glass microspheres cleaned and dried in step (1) in a 1mol / L NaOH solution, take them out after soaking for 2 hours under constant stirring, and take the complete microspheres and place them in a drying oven for drying. The dried hollow glass microspheres were immersed in a container containing 1.5×SBF solution of bioglass (the mass ratio of bioglass to hollow glass microspheres was 1:1), and placed in a constant temperature oscillator in a water bath, and the water temperature was adjusted to 36.5°C. The frequency is 80 times / min. After soaking for 2 days, take out and wash with deionized water and dry at room temperature.

[0025] (3) Immerse the hollow glass microspheres treated in step (2) into 1.5×SBF solution, put them i...

Embodiment 2

[0027] (1) Take the hollow glass microspheres in the middle of the two meshes sieved with 100 mesh and 140 mesh sieves, then clean them with deionized water, and place them in a blast drying oven until dry after cleaning.

[0028] (2) Immerse the hollow glass microspheres cleaned and dried in step (1) in a 1mol / L NaOH solution, take them out after soaking for 2 hours under constant stirring, and take the complete microspheres and place them in a drying oven for drying. The dried hollow glass microspheres were immersed in a container containing 1.5×SBF solution of bioglass (the mass ratio of bioglass to hollow glass microspheres was 0.2:1), and placed in a constant temperature oscillator in a water bath, and the water temperature was adjusted to 36.5°C. The frequency is 80 times / min. After soaking for 2 days, take out and wash with deionized water and dry at room temperature.

[0029] (3) Immerse the hollow glass microspheres treated in step (2) into 1.5×SBF solution, put them...

Embodiment 3

[0031] (1) Take the hollow glass microspheres in the middle of the two meshes sieved with 100 mesh and 140 mesh sieves, then clean them with deionized water, and place them in a blast drying oven until dry after cleaning.

[0032] (2) Immerse the hollow glass microspheres cleaned and dried in step (1) in a 1mol / L NaOH solution, take them out after soaking for 2 hours under constant stirring, and take the complete microspheres and place them in a drying oven for drying. The dried hollow glass microspheres were immersed in a container containing 1.5×SBF solution of bioglass (the mass ratio of bioglass to hollow glass microspheres was 0.2:1), and placed in a constant temperature oscillator in a water bath, and the water temperature was adjusted to 36.5°C. The frequency is 80 times / min. After soaking for 2 days, take out and wash with deionized water and dry at room temperature.

[0033] (3) Immerse the hollow glass microspheres treated in step (2) into 1.5×SBF solution, put them...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com