Improved method for synthesizing ranolazine

A synthesis method and technology of ranolazine, applied in the field of medicinal chemistry, can solve the problems of low total yield, unsuitable for industrial production, many steps, etc., and achieve the effects of reducing production cost and reducing reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

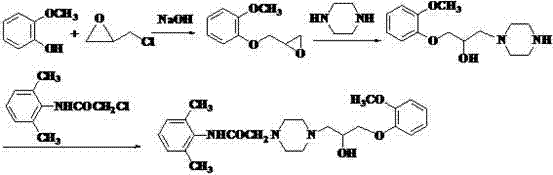

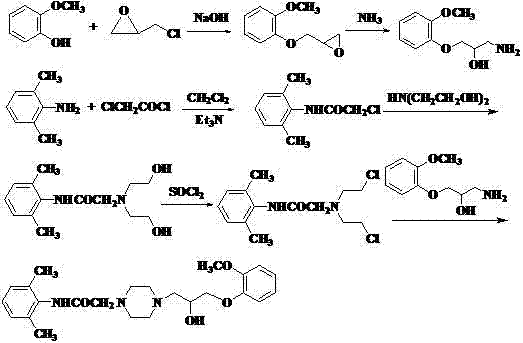

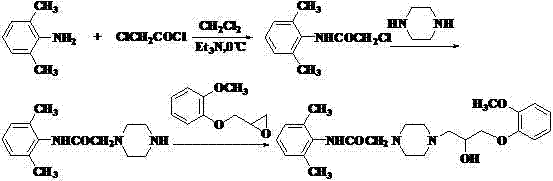

Method used

Image

Examples

Embodiment Construction

[0025] In order to better implement the present invention, the present invention is further described by giving examples, but the examples are not limitations of the present invention.

[0026] (1) Preparation of 2-(2-methylphenoxymethyl)oxirane

[0027] Add 49.6g (0.4mol) of o-methoxyphenol, 185g (2.0mol) of epichlorohydrin, 110.6g (0.4mol) of potassium carbonate, and 0.5g of benzyltriethylammonium chloride (TEBA) into a 500ml reaction bottle . Heat up to 70°C with stirring, react for 2 hours, cool to room temperature, filter, wash the filter cake with 60ml×2 epichlorohydrin, combine the filtrate, recover epichlorohydrin at 60-120°C / 50mmHg, collect 136.0-138.0°C / 30mmHg Distillation, the product 61.9g was obtained, the yield was 86.0%.

[0028] (2) Preparation of 2-chloro-N-(2,6 benzhydryl)acetamide

[0029] Put 36.4g (0.30mol) of 2,6-dimethylaniline, 600ml of dichloromethane, 31.8g (0.3mol) of sodium carbonate and 300ml of water into a 2000ml reaction bottle. Control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com