Ultraviolet (UV)/moisture dual-cured laminated adhesive and preparation method thereof

A moisture-curing, dual-curing technology, used in adhesives, adhesive types, polyether adhesives, etc., can solve problems such as inability to provide effective protection, and the glue cannot be UV cured, so as to avoid inability to cure and reduce production costs. , the effect of rapid curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific examples;

[0037] The present invention selects UV-curable (meth)acrylate resin, moisture-curable modified (meth)acrylate resin, (meth)acrylic reactive diluent, moisture-curable (meth)acrylic acid Reactive diluent, photoinitiator, catalyst, according to the appropriate formula ratio, to prepare UV / moisture dual curing film adhesive;

[0038] Below are the embodiments given by the inventor, but the present invention is not limited to these embodiments;

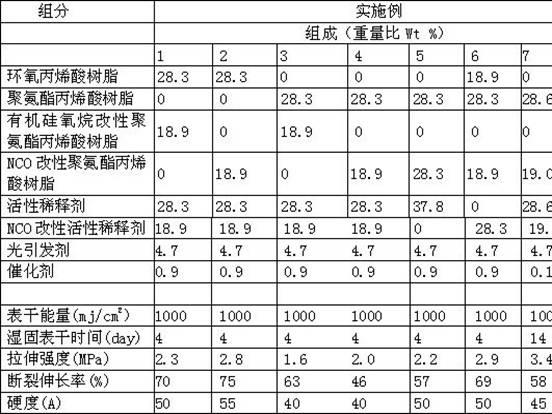

[0039]

[0040] Preparation method: Accurately weigh various raw materials according to the proportion of the formula, produce UV / moisture dual-curing film adhesive according to the aforementioned preparation process, test the surface-drying energy of the glue, the wet-cured surface-drying time, and the tensile strength and frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com