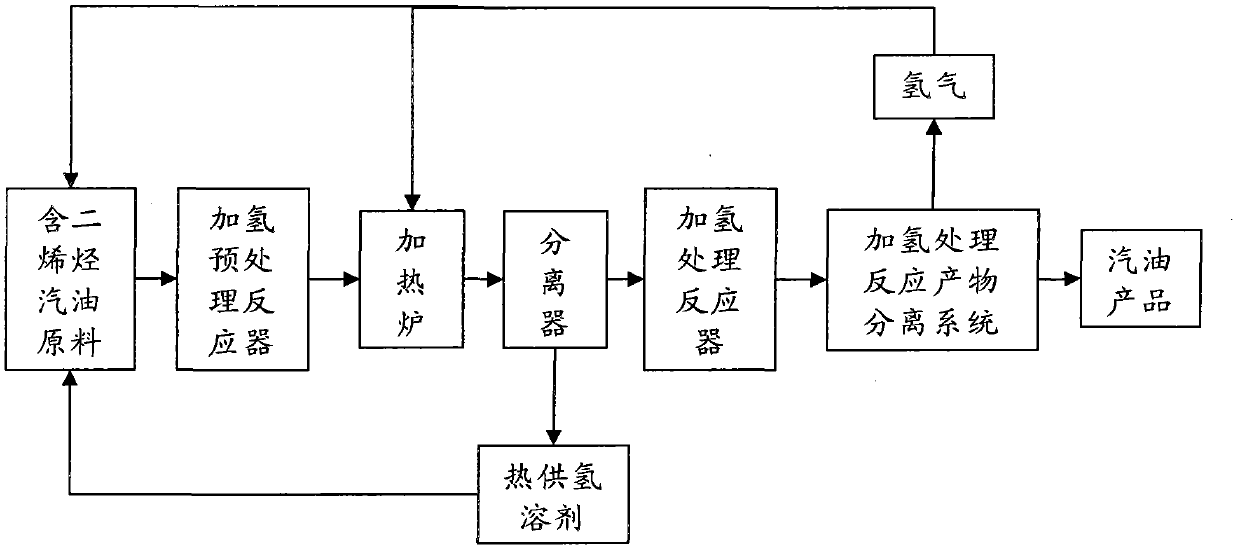

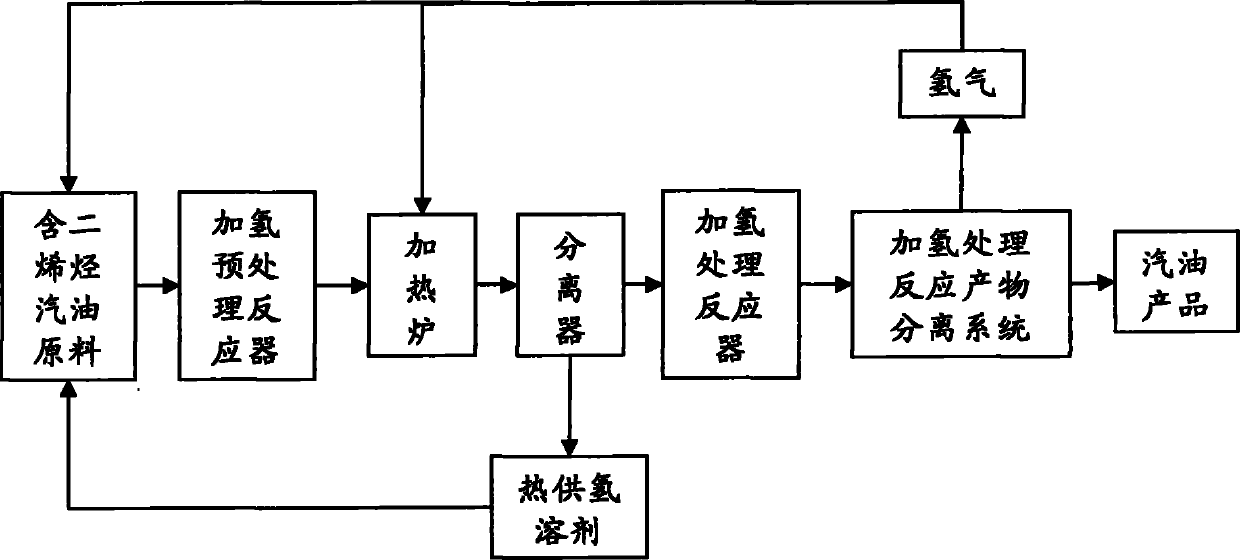

Dialkene-containing gasoline fraction hydrotreating method

A technology for hydrogenation treatment and gasoline fractionation, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc. It can solve the problems of coking of heat exchangers, etc., so as to increase the reaction speed of hydrogenation, improve the processing capacity, and improve the utilization of heat efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

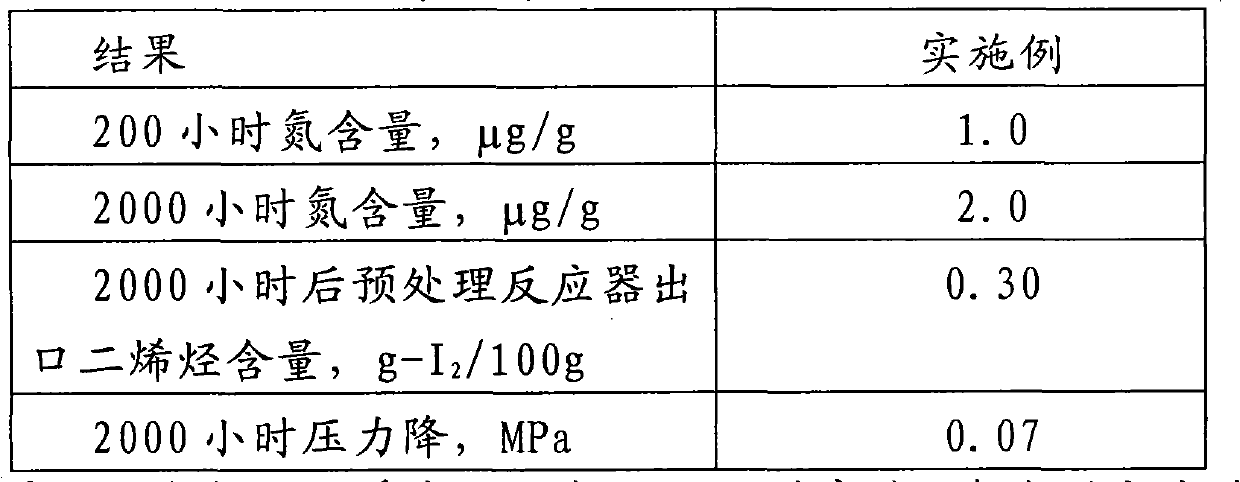

Examples

Example Embodiment

[0028] The present invention will be further described below in conjunction with preferred embodiments. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention. The embodiment adopts a small constant-temperature fixed-bed reactor in a laboratory, and the hydrogen supply solvent is tetralin.

[0029] Table 1 Feedstock oil properties

[0030] Raw oil name Coking gasoline fraction Density (20℃), g·cm -3 0.7210 Distillation range, ℃ 40~200 Sulfur content, wt% 0.79 Nitrogen content, wt% 0.02 Diolefin, g-I 2 / 100g 4.8 Bromine value, gBr.100g -1 71.0 Aromatics, v% 9.8

[0031] Table 2 The main composition and properties of the catalyst

[0032] catalyst Hydrotreating pretreatment catalyst Hydrotreating catalyst Catalyst composition MoO 3 +NiO / wt% 12 20 Carrier Alumina Alumina The main properties of the catalyst Specific surface, m 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap