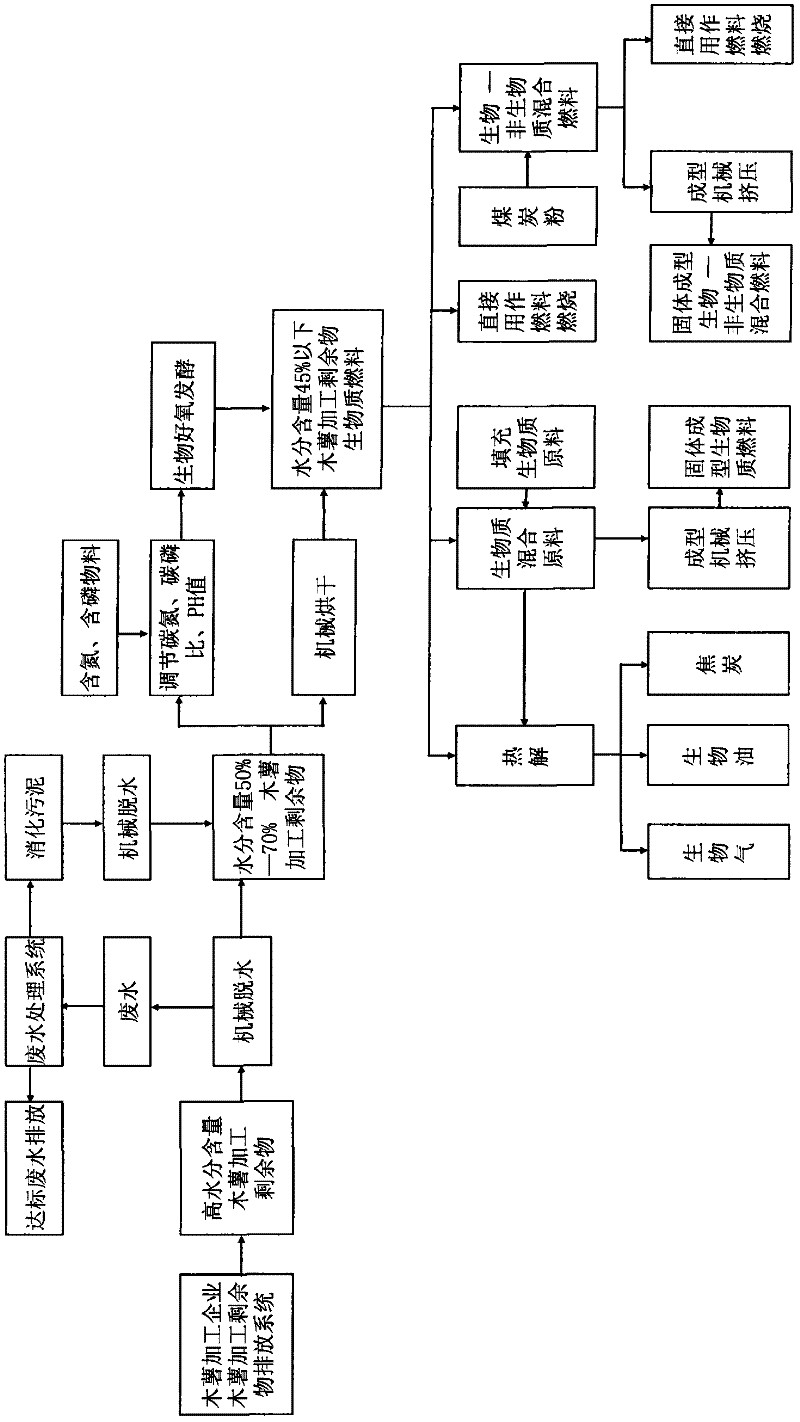

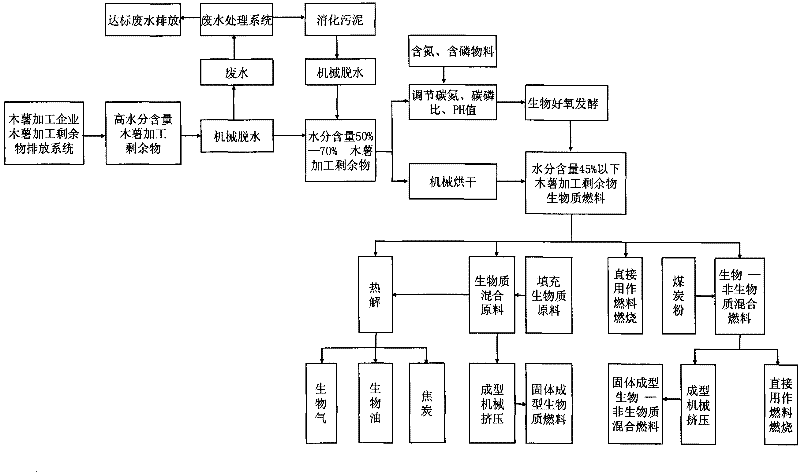

Method for preparing biomass fuel by utilizing processing residua of cassava

A technology for biomass fuel and processing residues, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of inability to timely process and use, breeding of large mosquitoes, waste of resources, etc., to avoid social resource waste, avoid The effect of secondary pollution and solving environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At the end of the cassava distiller's grains discharge pipeline of the cassava alcohol production enterprise, a centrifuge is installed to dehydrate the grains for the first time, and the cassava distillers' grains with a moisture content of about 85% are separated, and the cassava distiller's grains with a moisture content of about 85% are separated by a belt conveyor. The cassava distiller's residue is transported to the vacuum belt filter press for the second dehydration, reducing its moisture content to 60%, adjusting its carbon-nitrogen ratio to 25, carbon-phosphorus ratio to 100, and transporting it to the fermentation tank for 30 days. Type dynamic aerobic fermentation, make it dry until the water content is below 30%, and then transport it into a ring die extrusion granulator to extrude into cylindrical particles to prepare solid shaped biomass fuel.

[0026] During the preparation process, the wastewater separated during dehydration is discharged into the sewage...

Embodiment 2

[0028] At the end of the cassava slurry discharge pipeline of the cassava starch production enterprise, a centrifuge is installed to dehydrate the slurry for the first time, and the cassava starch residue with a moisture content of about 85% is separated, and the cassava with a moisture content of about 85% is separated by a belt conveyor. The starch slag is transported to the belt filter press for the second dehydration, and its moisture content is reduced to 65%. It is transported into the air dryer with a belt conveyor and dried to a moisture content of 30%. Sawdust with a moisture content of 10% is blended in a proportion and stirred evenly with a mixer to obtain a mixed biomass raw material with a moisture content of 24%, which is then transported into an extrusion granulator and extruded into cylindrical particles to prepare a solid shaped biomass fuel.

[0029] During the production process, the wastewater separated during dehydration is discharged into the sewage treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com