Method for improving anaerobic digestion performance of biomass wastes by biological phase separation and optimization technology

A technology of biomass waste and anaerobic digestion, which is applied in the field of solid waste treatment and resource utilization, can solve the problems that hinder the industrialization of two-phase anaerobic digestion technology, start-up technology and phase separation optimization technology have not been solved, and achieve reduction Small reactor volume, good system stability, and reduced treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

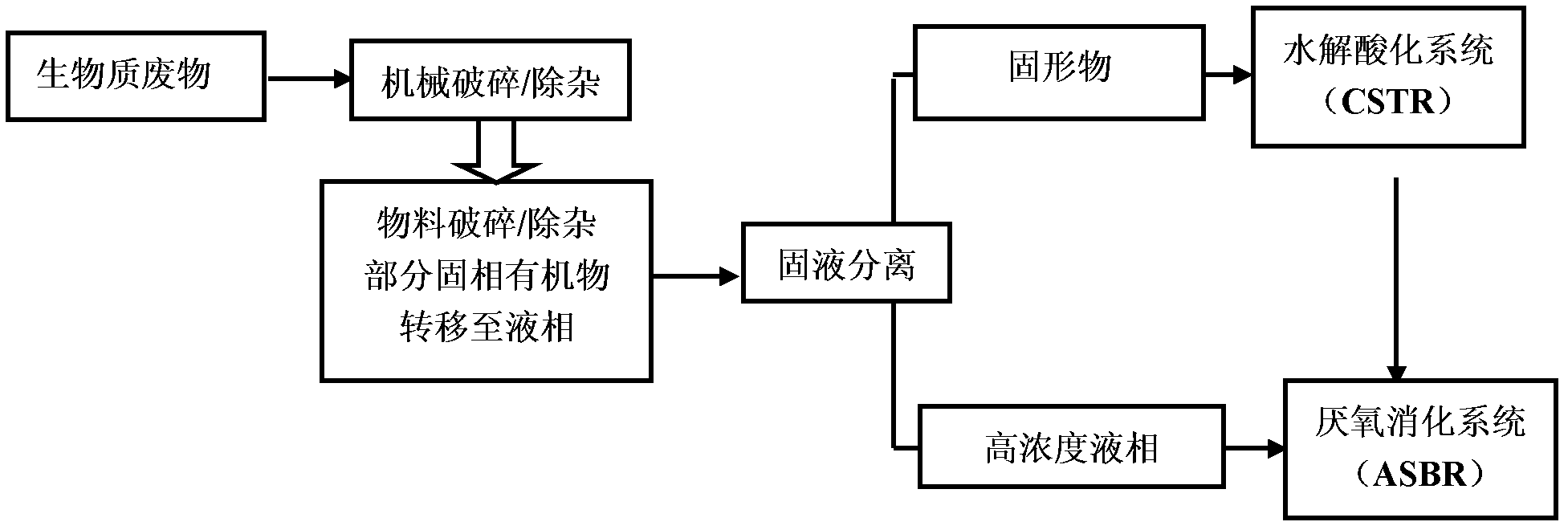

[0025] A method for improving the biogas yield of anaerobic digestion of biomass waste through biological phase separation optimization technology, comprising the following process steps:

[0026] 1. Raw material pretreatment: use a pulverizer and a juicer to crush the fruit and vegetable waste into a slurry, and realize solid-liquid separation. The screen aperture of the juicer is 1mm, the extrusion force is 300-600N, and the total juice volume is b ;

[0027] 2. Start-up and operation of the acidification phase: the acidification phase reactor adopts a complete mixing anaerobic fermentation reaction device (CSTR), the effective working volume is 5L, the reaction temperature is controlled at 35±1°C, and the stirring intensity is 120r·min -1 , stirring for 5min every 3h. The acidification phase starts with an organic load of 20gvs·L -1 , F / M=2, after 4 days of batch reaction, when the pH value of the system is stabilized in the range of 4.5 to 5.5, H 2 The content is around...

Embodiment 2

[0031] Embodiment 2: the specific implementation method is as follows:

[0032] A method for improving the biogas yield of anaerobic digestion of biomass waste through biological phase separation optimization technology, comprising the following process steps:

[0033] 1. Raw material pretreatment: crush fruit and vegetable waste into pulp with a shredder and a juicer, and realize solid-liquid separation. The screen aperture of the juicer is 1mm, and the extrusion force is 300-600N;

[0034] 2. Start-up and operation of the acidification phase: the acidification phase reactor adopts a complete mixing anaerobic fermentation reactor (CSTR), the effective working volume is 5L, the reaction temperature is controlled at 35±1°C, and the stirring intensity is 120r·min -1 , stirring for 5min every 3h. The acidification phase starts with an organic load of 20gvs·L -1 , F / M=2.5, after 3 days of batch reaction, when the pH value of the system is stabilized in the range of 4.5 to 5.5, H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com