After-forging preheat treatment process of large turbine low-pressure rotor forging piece

A pre-heat treatment and low-pressure rotor technology, which is applied in the field of post-forging pre-heat treatment process, can solve problems such as difficult production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For a 300MW steam turbine low-pressure rotor forging made of 26Cr2Ni4MoV steel, its rough machining diameter is Φ1850mm, and the forging diameter is Φ1920mm. Firstly, the sample was subjected to 1250°C×1.5h roughening treatment and 350°C×10h bainite treatment to obtain coarse austenite grains and acicular lower bainite structure. After the treatment, the sample grains greater than level 1.

[0014] Then the above treated samples were subjected to high temperature pre-tempering (660°C×20h) + critical zone normalizing treatment (770°C×3h) + normal normalizing (950°C×1h) treatment.

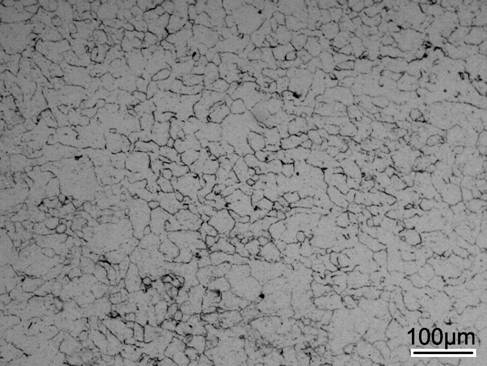

[0015] The treated sample was etched with supersaturated picric acid + sodium dodecylbenzenesulfonate solution to reveal austenite grain boundaries, and its grain size reached 7.5-8.0 grades.

[0016] Using high temperature pre-tempering + critical zone normalizing + normal normalizing process, the grain refinement effect is obvious, the heat treatment cycle is shortened, the heating temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com