Method for controlling surface decarburization of spring steel wires

A control method and spring steel technology, applied in the field of spring steel production, can solve the problems of affecting fatigue life, affecting fatigue performance, reducing spring fatigue strength and service life, etc., and achieving the effect of easy implementation, stable quality and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

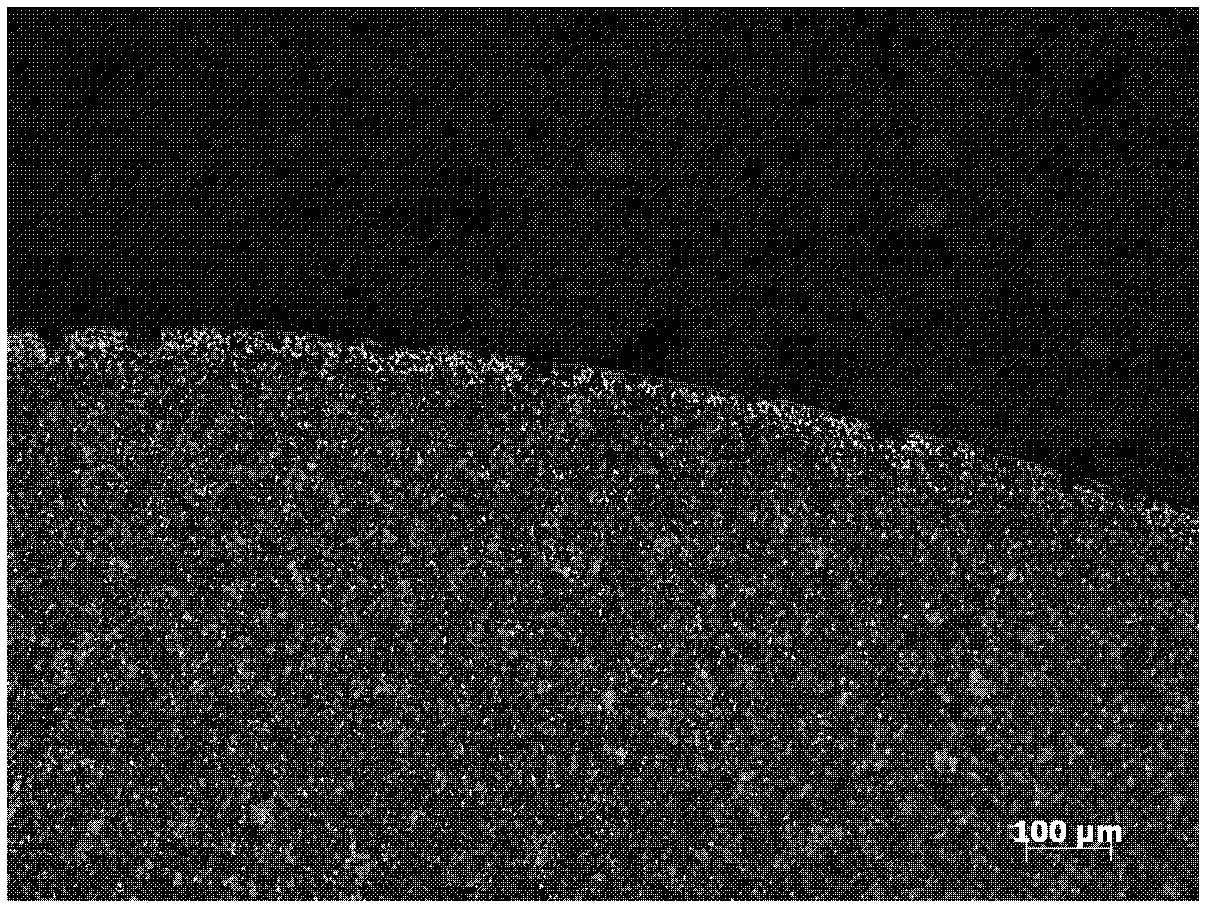

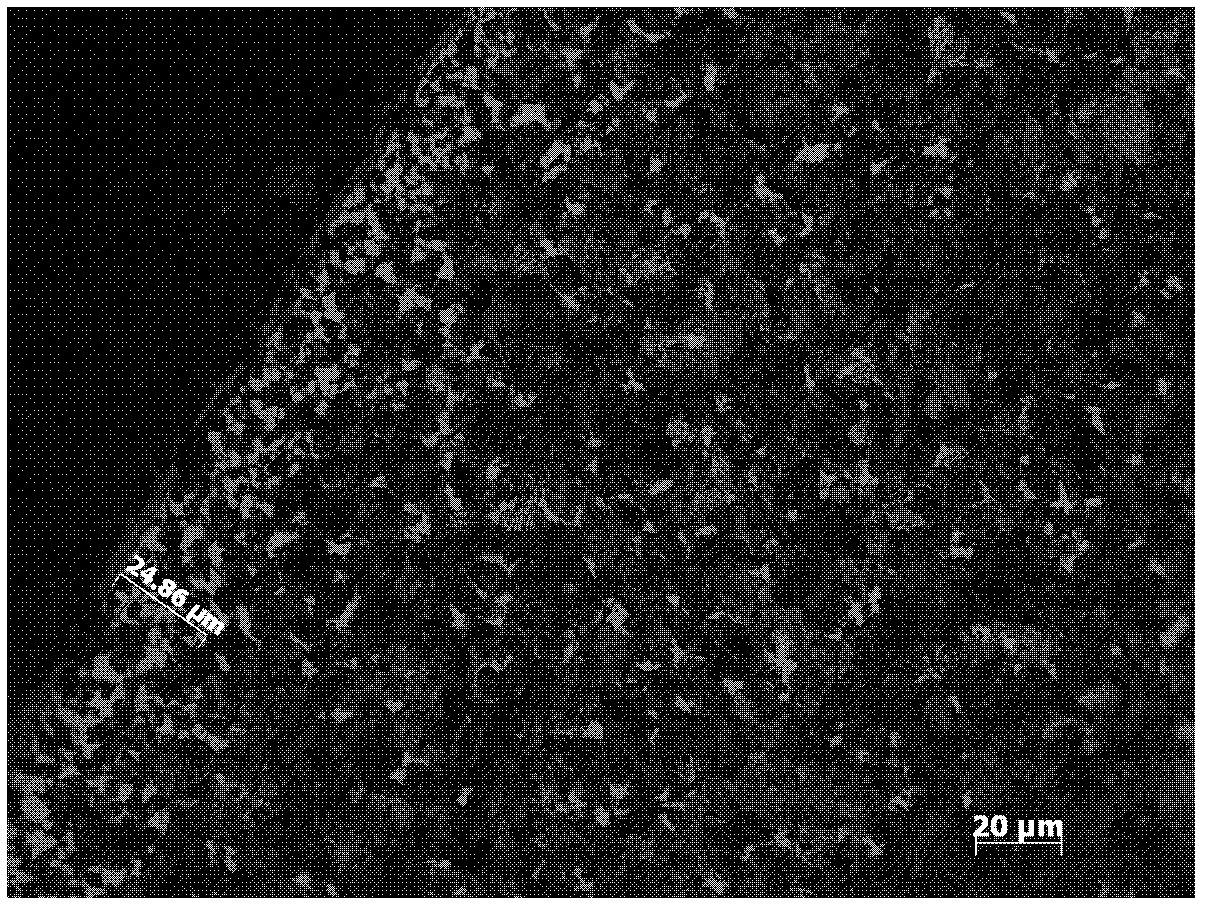

Image

Examples

Embodiment 1

[0022] Embodiment Example 1 The mass percentage of the chemical composition of the continuous casting slab is: C: 0.52%, Mn: 0.70%, Si: 1.50%, Cr: 0.72%, Ni: 0.35%, Cu: 0.25%, P: 0.0094%, S: 0.0023%, the balance is Fe.

[0023] The process flow of 55SiCr spring steel in this example is: acceptance of raw and auxiliary materials → batching → electric furnace smelting → LF refining → VD degassing → continuous casting → billet cooling inspection → billet acceptance → heating → descaling → rolling → spinning → cooling → Finished product inspection → bundling mark → weighing storage → delivery.

[0024] This embodiment is a continuous casting slab with a cross-sectional size of 150mm×150mm, rolling a 55SiCr spring steel wire rod with a diameter of 12mm, and the decarburization control method on the wire rod surface is as follows:

[0025] Heating furnace heating process: In order to reduce the thickness of the oxidation and decarburization layer during the heating process of the b...

Embodiment 2

[0030] Implementation Example 2 The mass percentage of the chemical composition of the continuous casting slab is: C: 0.52%, Mn: 0.68%, Si: 1.48%, Cr: 0.70%, Ni: 0.3%, Cu: 0.2%, P: 0.0076%, S: 0.0015%, the balance is Fe.

[0031] The process flow of 55SiCr spring steel in this example is: acceptance of raw and auxiliary materials → batching → electric furnace smelting → LF refining → VD degassing → continuous casting → billet cooling inspection → billet acceptance → heating → descaling → rolling → spinning → cooling → Finished product inspection → bundling mark → weighing storage → delivery.

[0032] This embodiment is a continuous casting slab with a cross-sectional size of 150mm×150mm, rolling a 55SiCr spring steel wire rod with a diameter of 10mm, and the decarburization control method on the wire rod surface is as follows:

[0033] Heating furnace heating process: In order to reduce the thickness of the oxidation and decarburization layer during the heating process of the...

Embodiment 3

[0038] Implementation Example 3 The mass percentage of the chemical composition of the continuous casting slab is: C: 0.54%, Mn: 0.67%, Si: 1.49%, Cr: 0.69%, Ni: 0.25%, Cu: 0.15%, P: 0.0096%, S: 0.0034%, the balance is Fe.

[0039] The process flow of 55SiCr spring steel in this example is: acceptance of raw and auxiliary materials → batching → electric furnace smelting → LF refining → VD degassing → continuous casting → billet cooling inspection → billet acceptance → heating → descaling → rolling → spinning → cooling → Finished product inspection → bundling mark → weighing storage → delivery.

[0040] This embodiment is a continuous casting slab with a cross-sectional size of 150mm×150mm, rolling a 55SiCr spring steel wire rod with a diameter of 18mm, and the decarburization control method on the wire rod surface is as follows:

[0041] Heating furnace heating process: In order to reduce the thickness of the oxidation and decarburization layer during the heating process of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com