Radiation hardening material with insulation buried layer and preparation method of radiation hardening material

An insulating buried layer and radiation reinforcement technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as difficulty in recovery, affect device or circuit performance, damage the integrity of insulating buried layers, etc., and achieve precise control. , to avoid injection damage and the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] figure 1 Shown is a flow chart of the steps of Embodiment 1 of the preparation method of a radiation-reinforced material with an insulating buried layer provided by the present invention.

[0033] This embodiment provides a method for preparing a radiation-reinforced material with an insulating buried layer, including: step 101, providing a device substrate and a supporting substrate; step 102, forming a growing the first and second insulating layers respectively; step 103, depositing a nanocrystal composite layer on the exposed surface of the first insulating layer by chemical vapor phase; step 104, bonding the exposed surface of the second insulating layer to bonded to the exposed surface of the one nanocrystal composite layer; step 105, annealing the bonded first, second and third insulating layers; step 106, thinning or Increase thickness to target thickness.

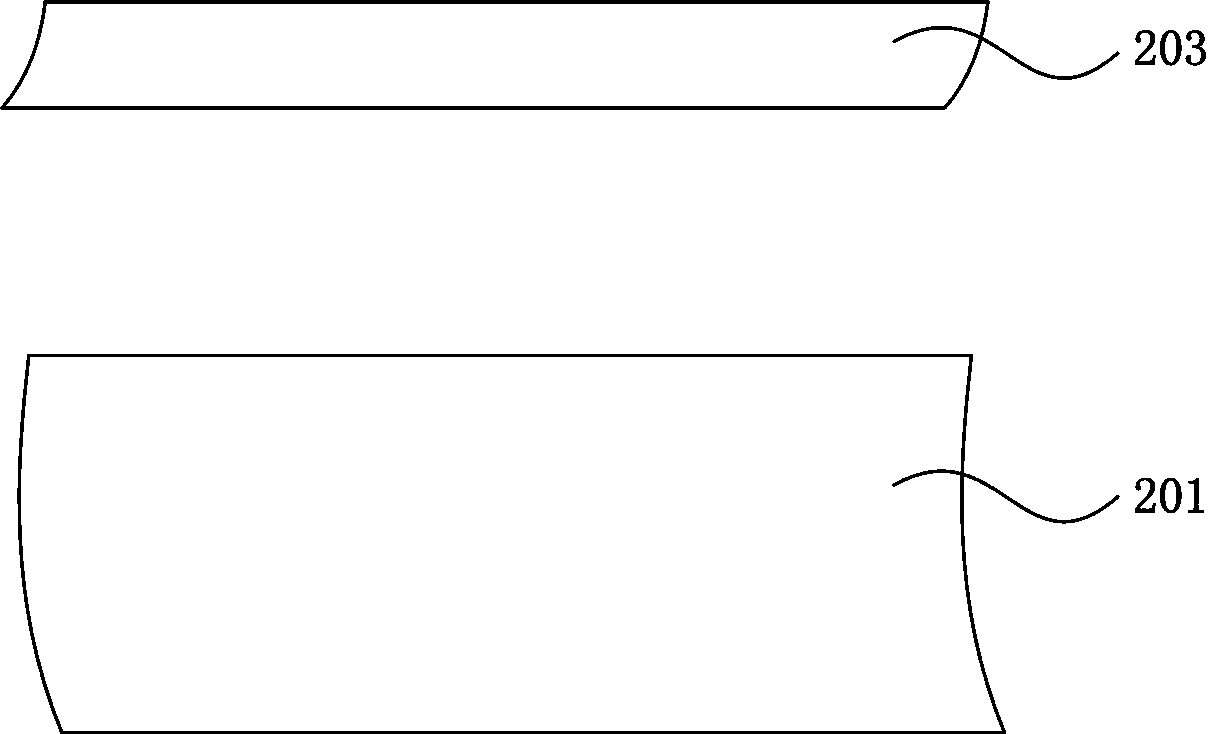

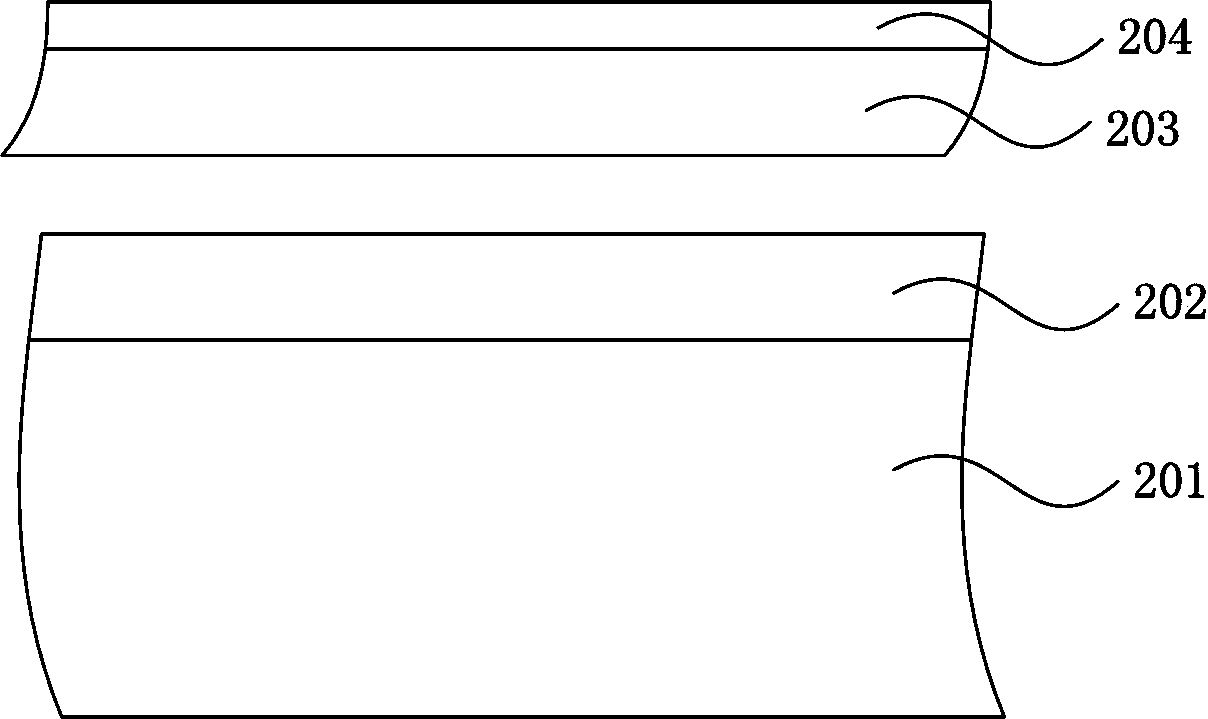

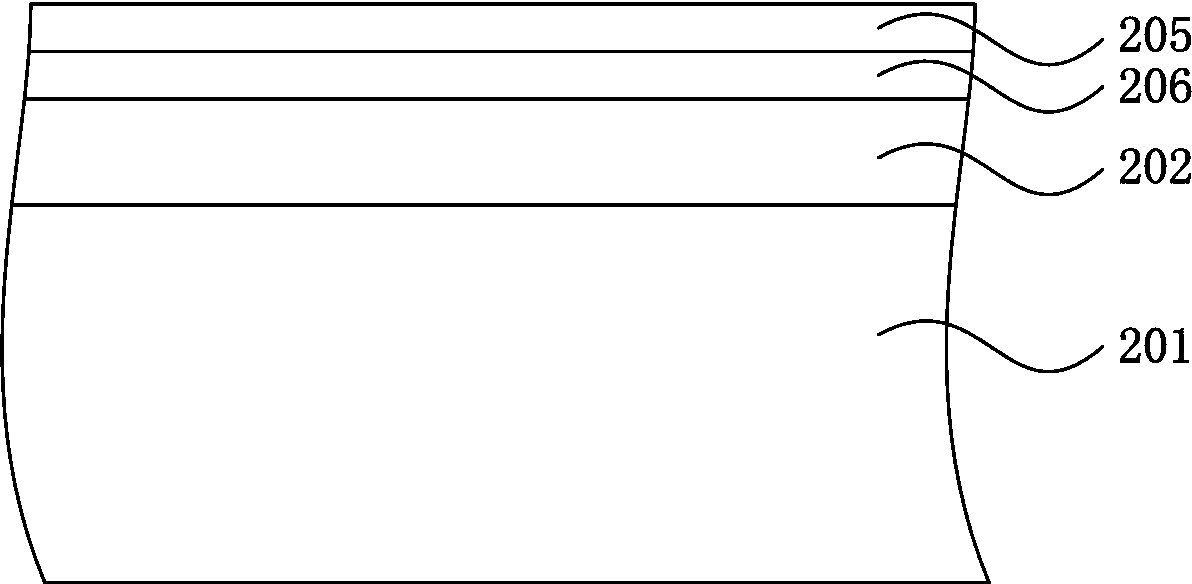

[0034] Figure 2A-2D Shown is a process flow chart of Embodiment 1 of the preparation method of a radia...

Embodiment 2

[0053] This embodiment provides a radiation-reinforced material with an insulating buried layer, the structure of which is as follows Figure 2D As shown, it is prepared by a bonding process, including a device substrate 201, an insulating buried layer and a supporting substrate 203 in sequence. The insulating buried layer includes a layer of nanocrystal composite layer placed in the insulating buried layer, and the nano The crystal composite layer sequentially includes a nanocrystal layer 206 and a third insulating layer 205, and the nanocrystal composite layer is formed by chemical vapor deposition, and the interface between the nanocrystal layer 206 and the first insulating layer 202 It is a bonding interface, and the interface between the nanocrystal layer 206 and the second insulating layer 204 is a bonding interface; the insulating buried layer further includes a first insulating layer 202, placed between the device substrate 201 and the layer Between the nanocrystal com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com