Graphite storage battery and preparation method thereof

A storage battery and graphite technology, which is applied in the direction of lead-acid battery, lead-acid battery construction, final product manufacturing, etc., can solve the problems of production environment and atmospheric environment pollution, and achieve the effects of shortening charging time, reducing lead consumption, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

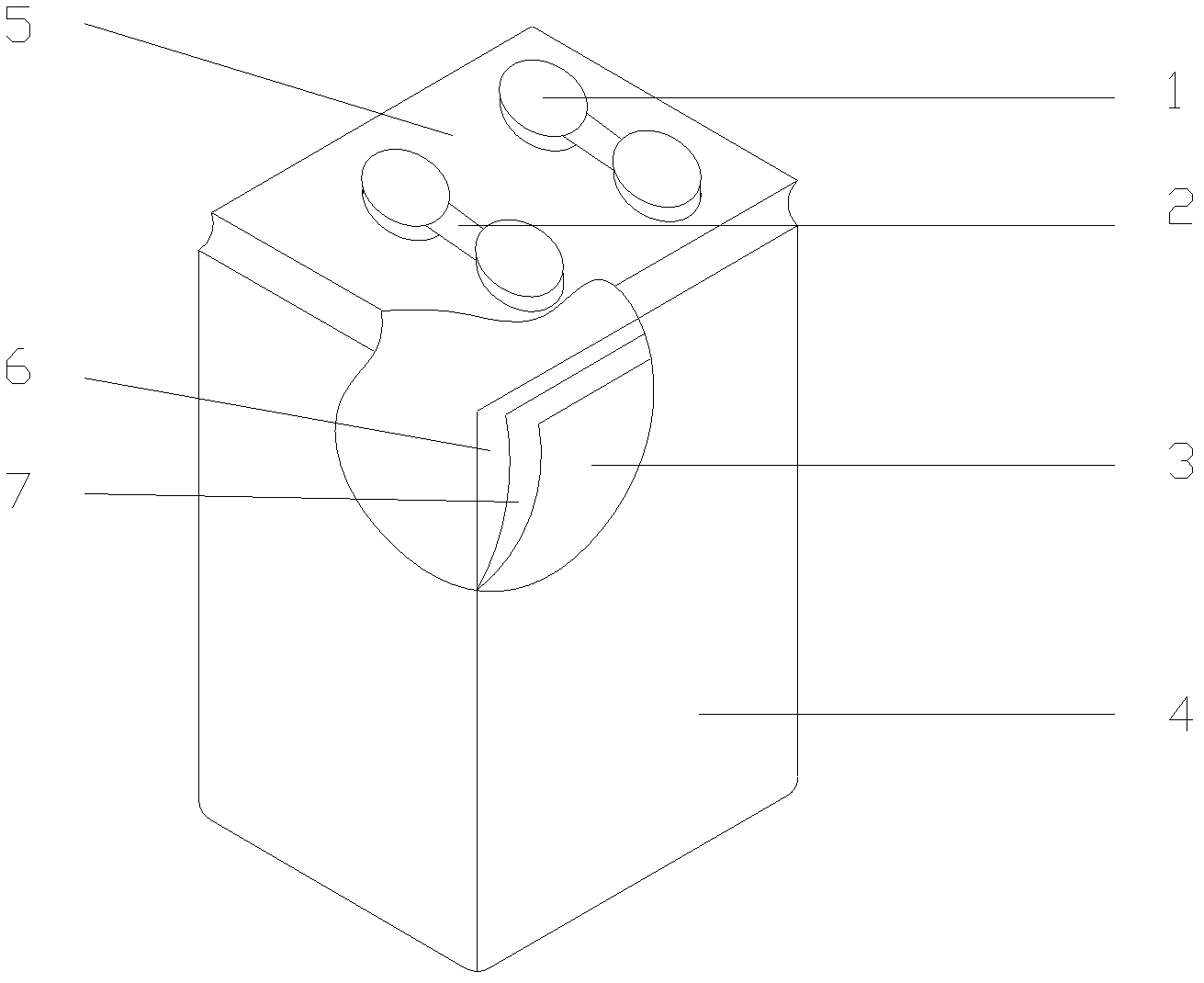

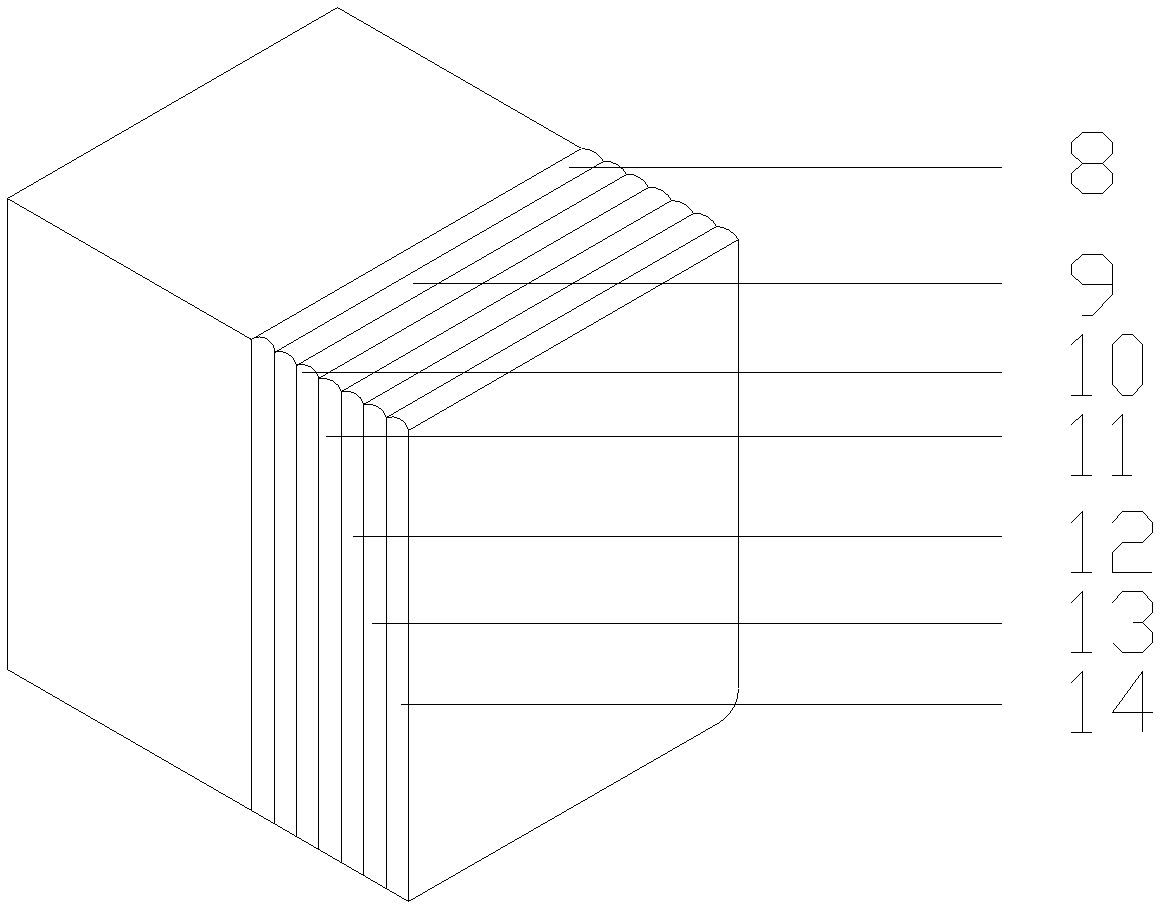

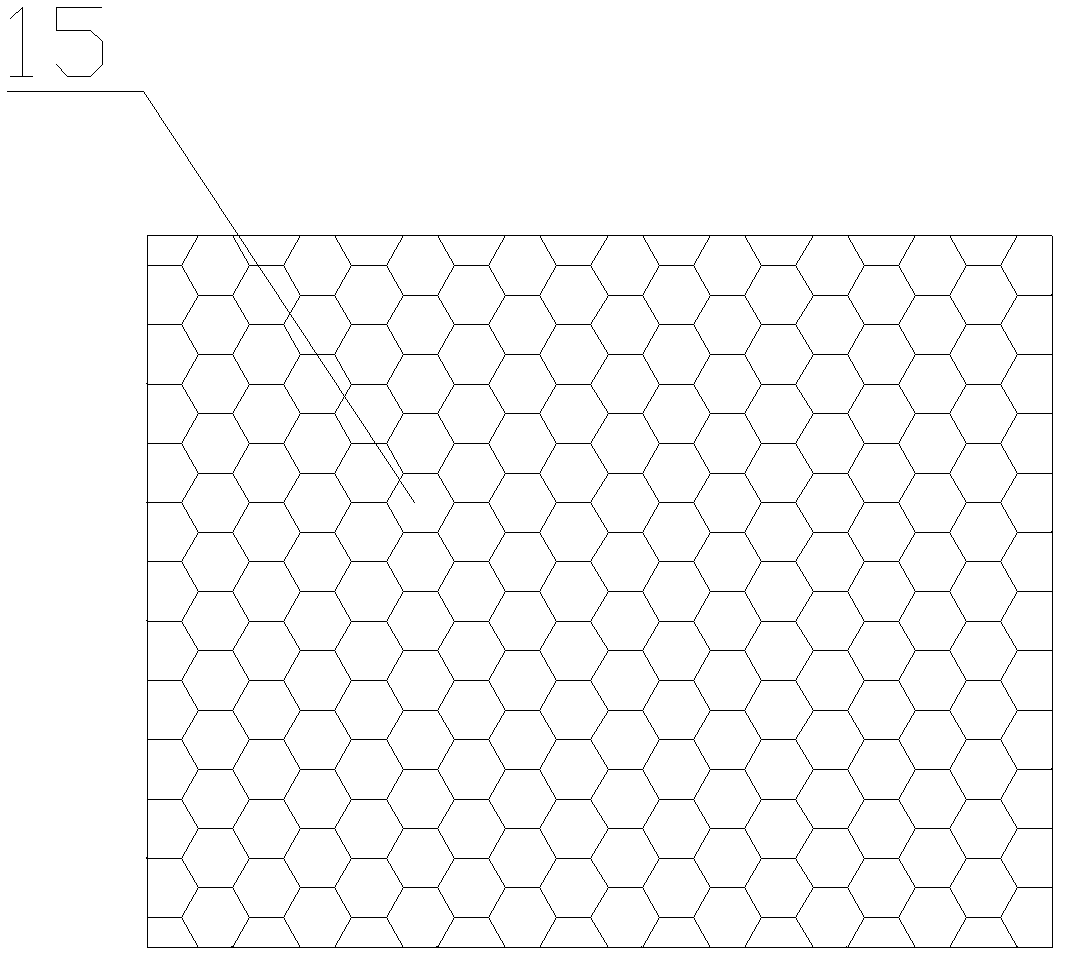

[0037] The utility model relates to a graphite accumulator, with a positive plate, a negative plate and an electrolyte in the battery case. The positive plate of the graphite battery is a positive grid structure, the positive grid is a mixed material of graphite and phenolic resin, and the mass ratio of phenolic resin to graphite powder is 1.3:1. The positive electrode grid is a honeycomb grid framework made by stamping and high-temperature sintering, and the thickness of the honeycomb grid framework is 3mm. The honeycomb grid framework of the positive grid is compounded with lead plating, with a thickness of 0.6mm. The negative plate is a negative grid structure, the negative grid is made of ABS engineering plastic material, and the honeycomb grid skeleton is made by injection molding, and the thickness of the honeycomb grid skeleton is 4mm. A polyaniline conductive coating is sprayed on the honeycomb grid skeleton of the negative electrode grid, and the thickness of the pol...

Embodiment 2

[0039] A preparation method of a graphite accumulator, comprising the preparation of a positive plate and a negative plate, paste coating, drying, assembling, pouring electrolyte, and packaging processes. The preparation process of positive plate and negative plate is as follows:

[0040] 1. Positive electrode grid preparation: The positive electrode plate is a positive electrode grid structure, and the positive electrode grid is made of graphite and phenolic resin mixed slurry to make a foaming material. The mass ratio of phenolic resin and graphite powder is 1.3:1 by stamping. After sintering at a high temperature of 300-600°C, the honeycomb grid skeleton is made, and the thickness of the honeycomb grid skeleton is 3mm.

[0041] 2. Lead-plating composite: the honeycomb grid skeleton of the positive grid is coated with lead powder on the honeycomb grid skeleton of the positive grid by spraying to make a composite positive grid; the thickness of the lead coating is 0.6mm .

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com