Laser-pumped flowing nano-particle rare-earth ion laser

A technology for pumping lasers and rare earth ions, applied in the field of lasers, can solve problems such as the difficulty of a single fiber laser to achieve a 100-kilowatt output, serious thermal effects of solid-state lasers, and non-recyclable fuels, achieving good heat dissipation effect, large mode volume, Less waste heat generation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

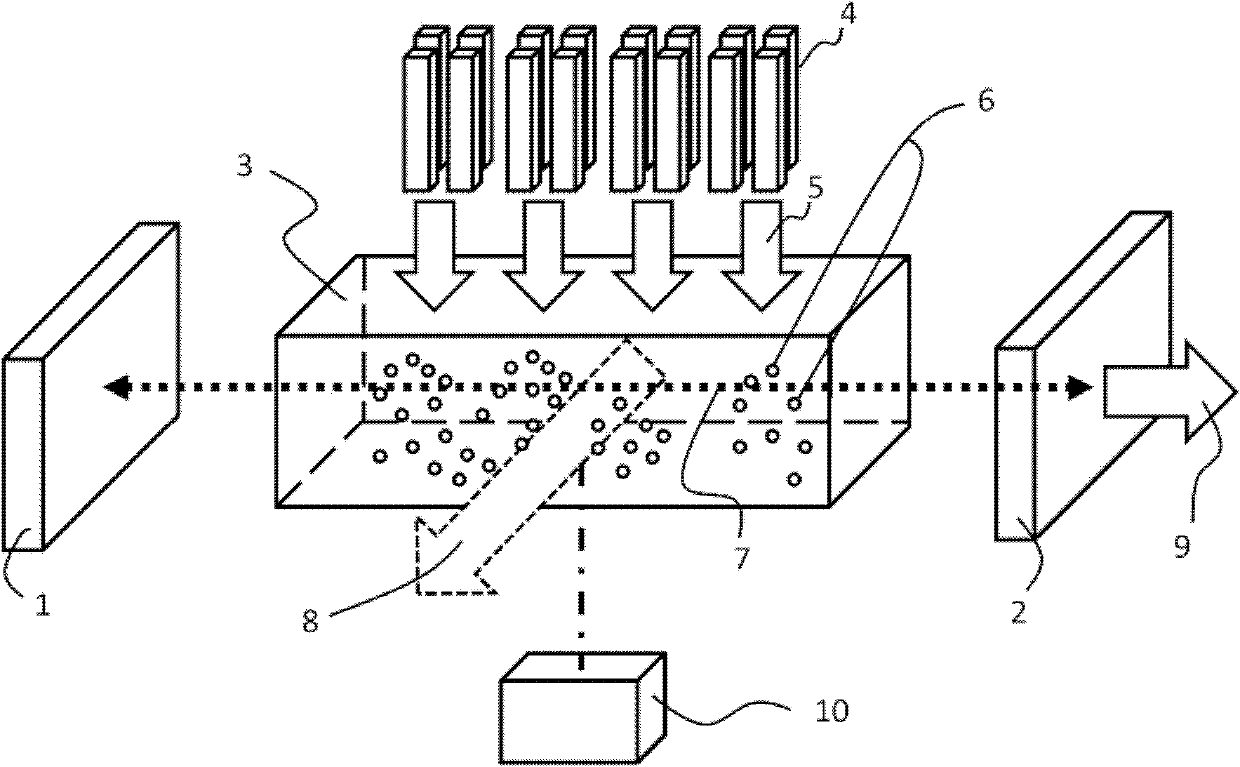

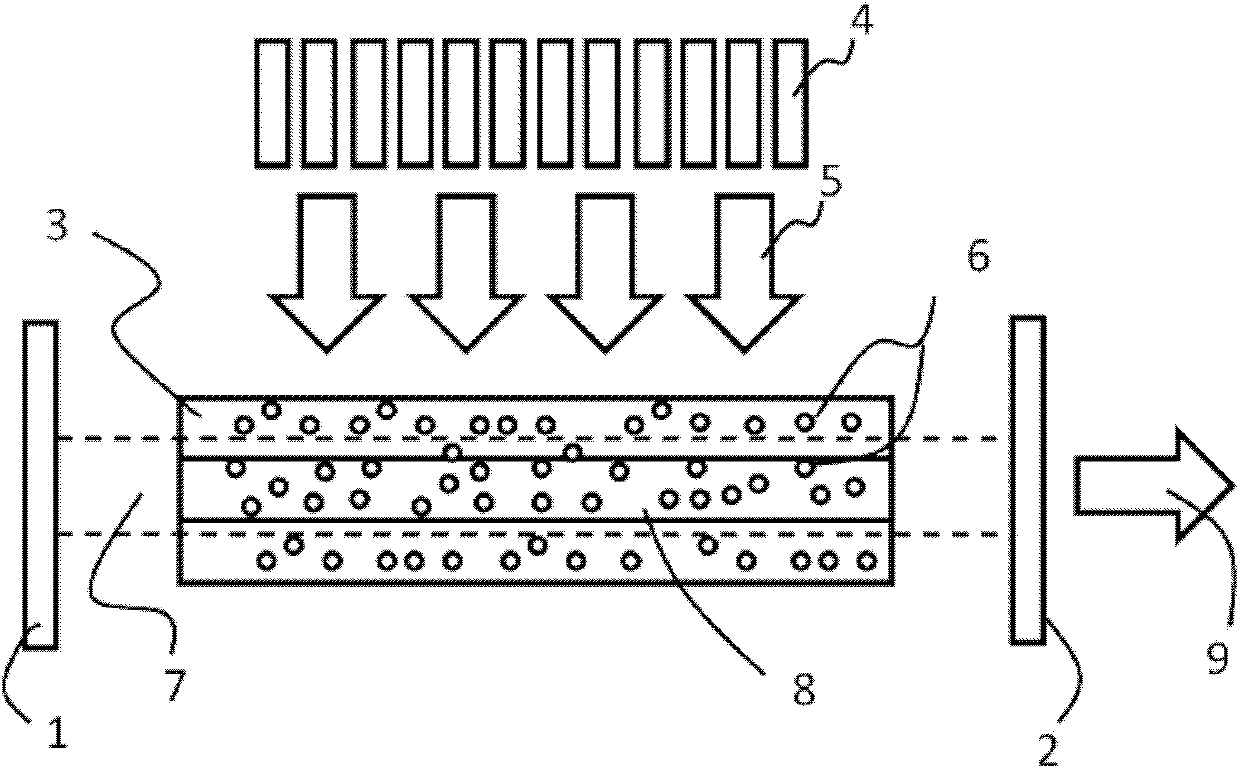

[0032] a kind of like Figure 1 ~ Figure 4 The laser-pumped flow nanoparticle rare earth ion laser of the present invention is shown, the laser includes a pump laser 4, a gas working chamber 3 and a resonant cavity.

[0033] The gas working chamber 3 of this embodiment is a rectangular parallelepiped of quartz glass coated with an anti-reflection film. The gas working chamber 3 is filled with a gain medium 6 that can be excited to a high energy state by the pump light 5 emitted by the pump laser 4. The gain medium 6 is mainly nanoparticles containing rare earth ions; the gain medium 6 in this embodiment is an average particle Yb with a diameter of 80nm 2 o 3 powder (the Yb 2 o 3 The powder was provided by Shanghai Institute of Ceramics with a purity of 99.9%). Nano Yb containing rare earth ions 2 o 3 After the powder is loaded into the gas working chamber 3, the circulation of the nano-rare earth ions, the oscillation output of the pump light 5 and the laser 7 can be co...

Embodiment 2

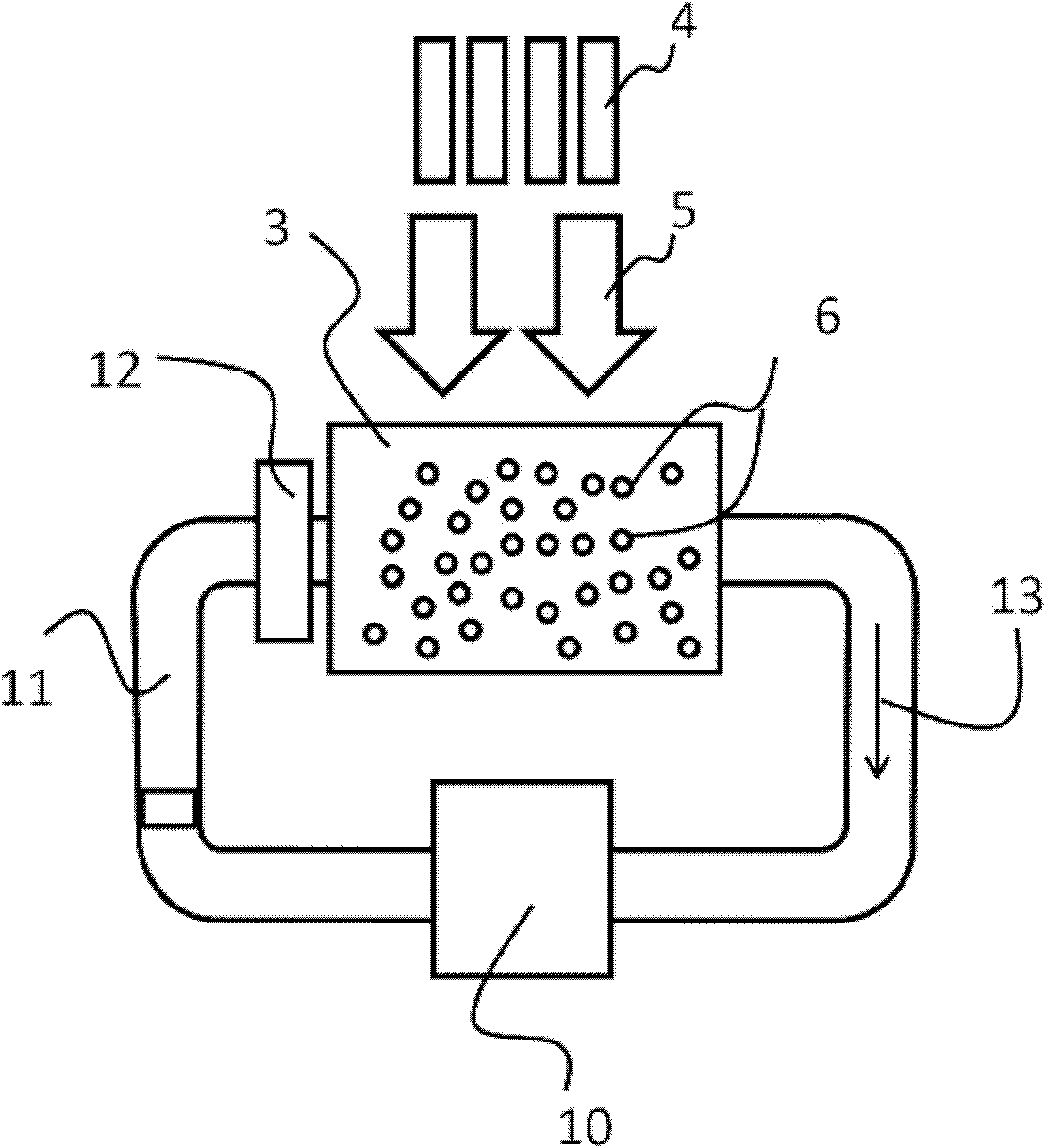

[0040] a kind of like Figure 4 The laser-pumped flow nanoparticle rare earth ion laser of the present invention shown, the gas laser includes a pump laser 4, a coupling mirror system 14, a gas working chamber 3 and a resonant cavity.

[0041] The gas working chamber 3 of this embodiment is a rectangular parallelepiped of quartz glass coated with an anti-reflection film. The gas working chamber 3 is filled with a gain medium 6 that can be excited to a high energy state by the pump light 5 emitted by the pump laser 4. The gain medium 6 is mainly nanoparticles containing rare earth ions; the gain medium 6 in this embodiment is an average particle Yb with a diameter of 80nm 2 o 3 powder (the Yb 2 o 3 The nanopowder was provided by Shanghai Institute of Ceramics with a purity of 99.9%). Nano Yb containing rare earth ions 2 o 3 After the powder is loaded into the gas working chamber 3, the circulation of the nano-rare earth ions can be controlled from a pair of working surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com